Drill pipe double-clamping system for pile driver

A technology for pile drivers and drill pipes, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., which can solve problems such as the inability to guarantee the verticality of drill pipes, the impact on the continuity of drilling work, and the limited length of telescopic drill pipes, etc., to achieve operational efficiency Improve, ensure verticality, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

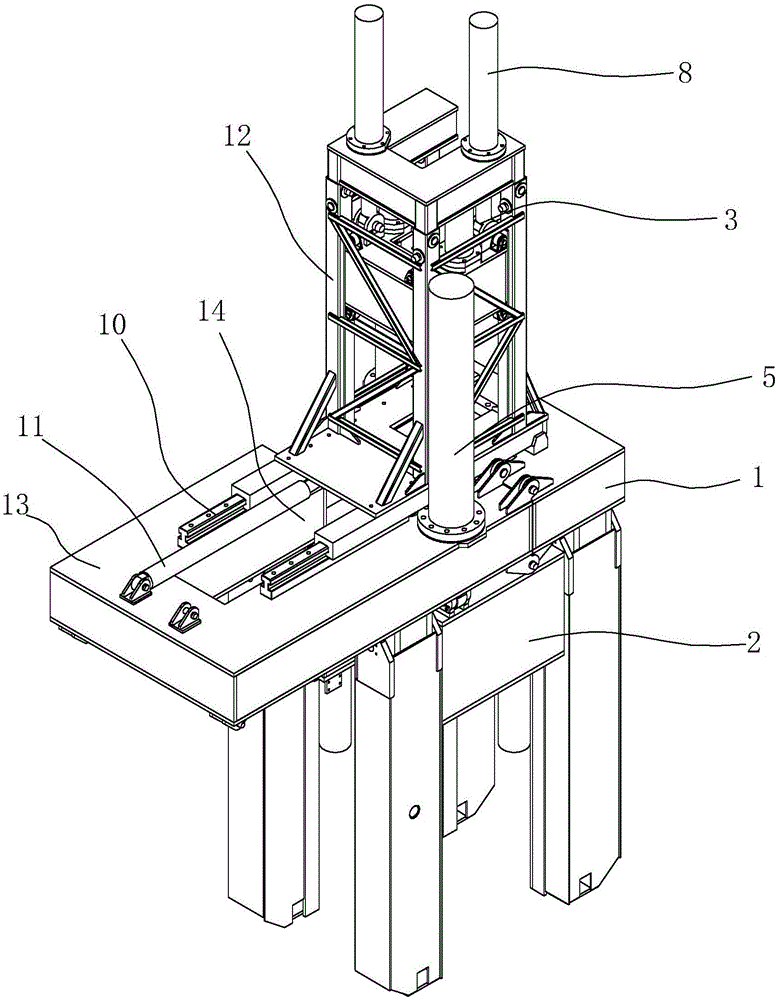

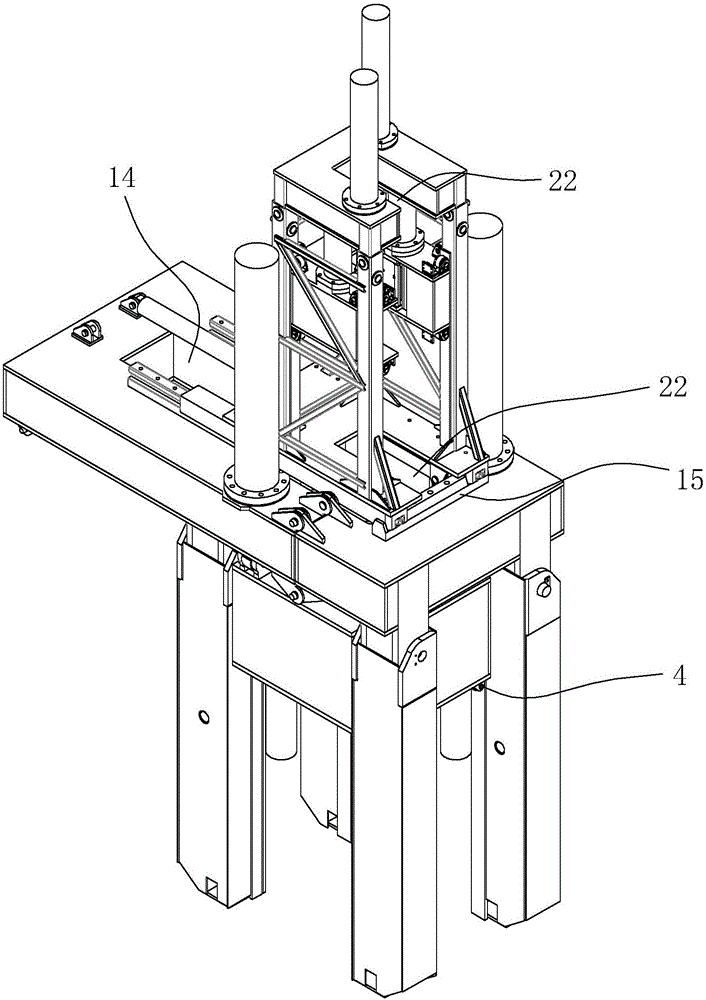

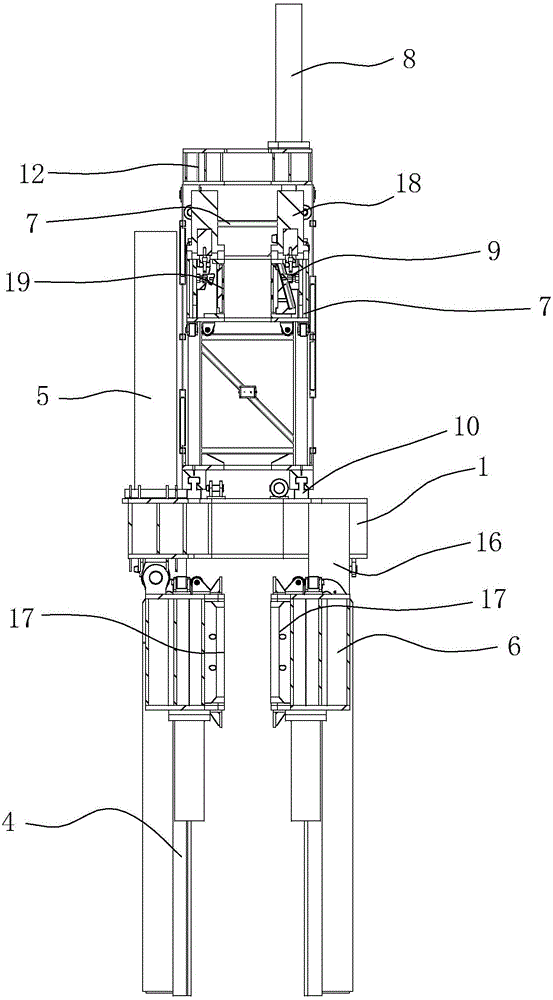

[0028] Such as figure 1 and Figure 6 As shown, a drill pipe double-hugging pressure system for a pile driver includes a pressure-hugging platform 1. The pressure-hugging platform 1 is provided with a tool for holding the drill pipe 100 and can drive the drill pipe in the vertical direction. The primary holding pressure mechanism 2 of the movement, the holding pressure table 1 is also provided with a secondary holding pressure mechanism 3 that can hold the drill pipe 100 tightly and drive the drill pipe to move in the vertical direction, and when the above described When the secondary holding pressure mechanism 3 tightly hugs the drill pipe, the axis line of the secondary holding pressure mechanism 3 coincides with the axis line of the primary holding pressure mechanism 2 .

[0029] Those skilled in the art should understand that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com