Low-strain double-speed signal averaging detection method for building hollow pile

A speed signal and detection method technology, applied in the field of building detection, can solve the problems of eccentric torque shear wave without in-depth consideration of three-dimensional interference signals, and no clear low-strain test plan, etc., to achieve the elimination of three-dimensional interference signals and eccentric effect shear wave, the effect of accurate pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

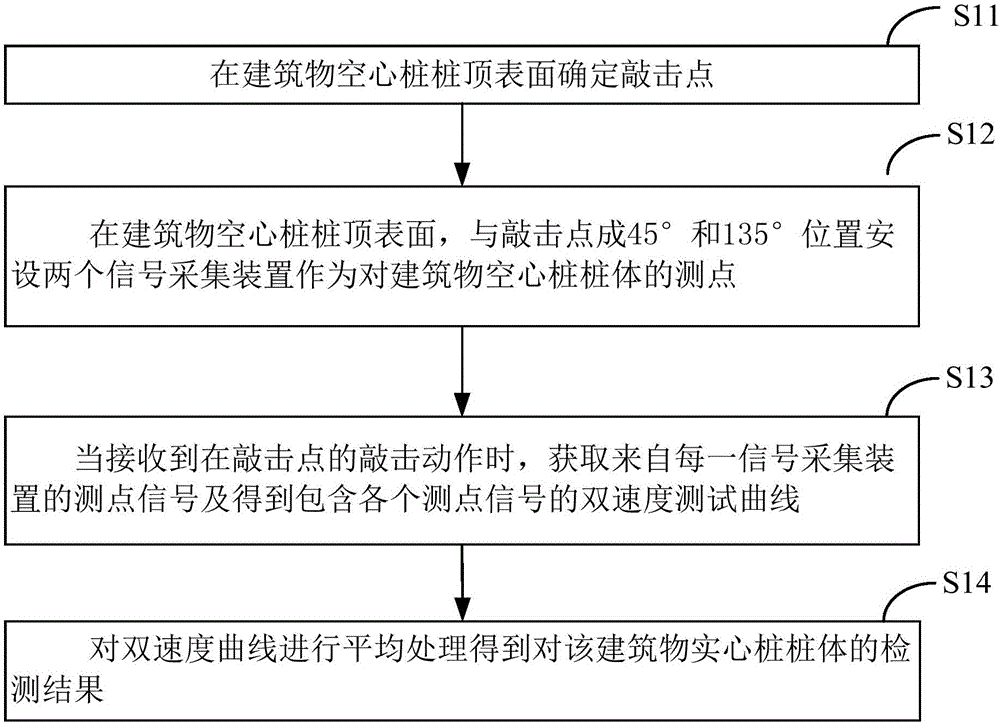

[0050] figure 1 It is a schematic flowchart of a low-strain double-velocity signal average detection method for building hollow piles of the present invention. The low-strain double-velocity signal average detection method of the hollow pile of the building is applied to the hollow pile of the building, and the method includes the following steps:

[0051] In step S11, the knocking point is determined on the top surface of the hollow pile of the building.

[0052] Specifically, the building hollow pile body can be a circular, square or polygonal hollow pile. The knocking action is vertical knocking with a force hammer or a force bar. For circular hollow piles, the knocking point is located at any position on the top surface of the pile at 1 / 2 of the pile wall thickness. For square and polygonal hollow piles, the knocking point is located at 1 / 2 of the pile wall thickness on the top surface of the pile, the midpoint of the side length or the intersection of two adjacent side...

Embodiment 2

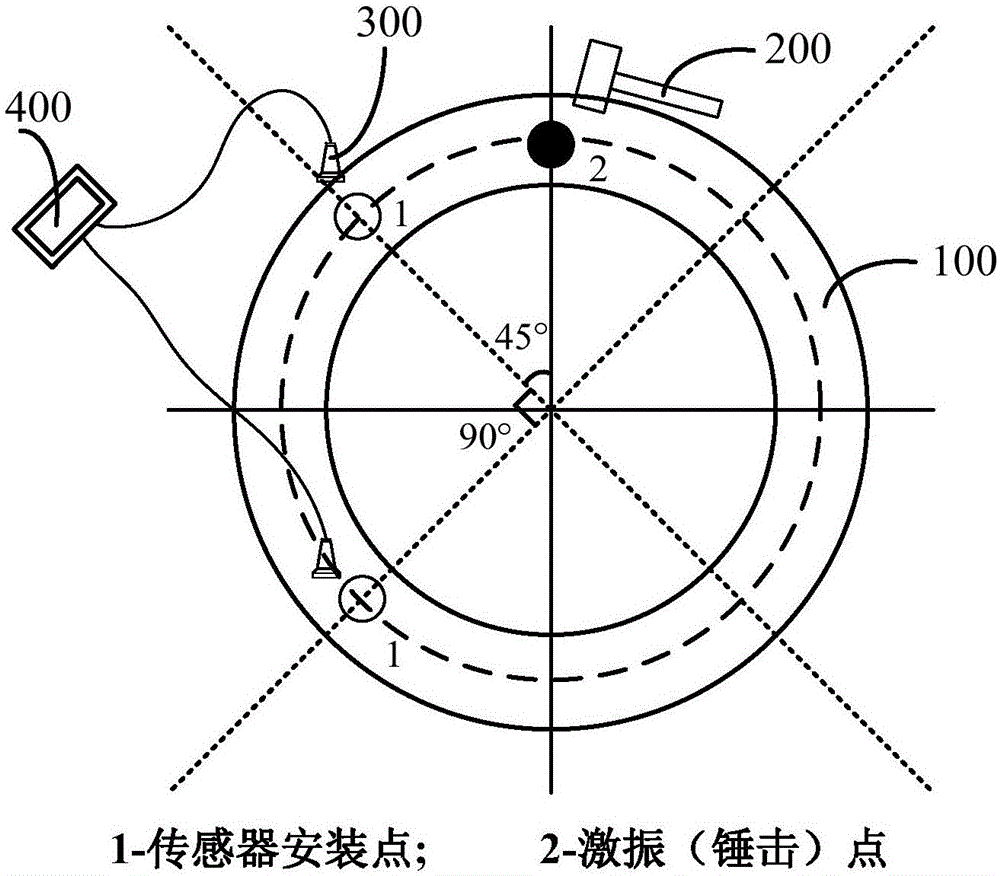

[0066] figure 2 It is a first structural schematic diagram of a low-strain double-velocity signal average detection method for building hollow piles in the present invention. In this embodiment, the building hollow pile is a circular hollow pile.

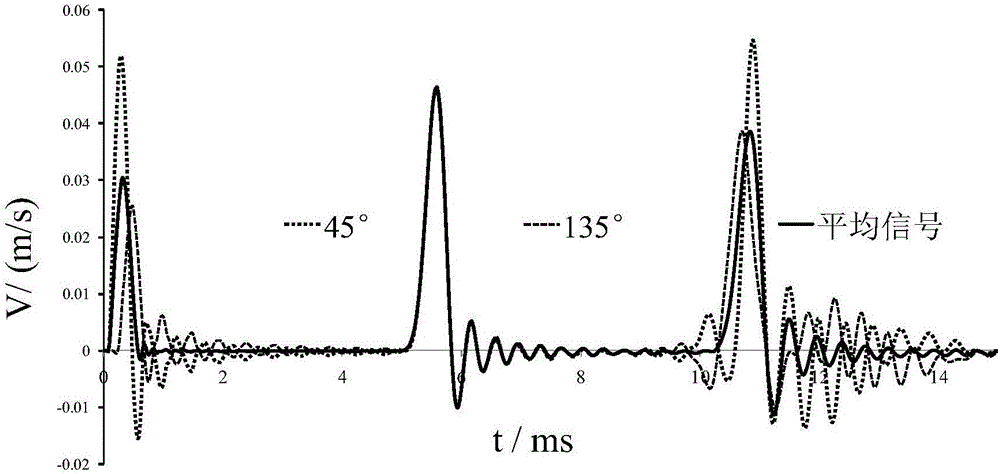

[0067] The vibration excitation device 200 generates a percussion action at any point on the pile top surface of the circular hollow pile 100, at 1 / 2 of the wall thickness, at 1 / 2 of the pile top surface wall thickness of the circular hollow pile 100, and Two signal acquisition devices are installed at the 45° and 135° positions of the knocking point as the measuring points for the hollow pile body. The information processing device 400 is a low-strain detector with a dual-speed mode, and the test mode adopts the dual-speed mode.

[0068] When the vibration excitation device 200 generates a knock action on the pile top surface of the circular hollow pile 100, a dual-velocity signal including two velocity curves can be obtained th...

Embodiment 3

[0078] Figure 8 It is a second structural schematic diagram of a low-strain double-velocity signal average detection method for building hollow piles in the present invention. In this embodiment, the building hollow pile is a square hollow pile.

[0079] The vibration excitation device 200 produces a knocking action at 1 / 2 of the pile wall thickness on the pile top surface of the square hollow pile 100, and at the midpoint of the side length, and at 1 / 2 of the pile top surface wall thickness of the square hollow pile 100, and Two signal acquisition devices are installed at the 45° and 135° positions of the knocking point as the measuring points for the hollow pile body. The information processing device 400 is a low-strain detector with a dual-speed mode, and the test mode adopts the dual-speed mode.

[0080] For specific tapping and sampling steps, see Example 2, which will not be repeated here.

[0081] Please also refer to Figure 9 , Figure 9 Yes Figure 8 The seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Pile diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com