Multifunctional installation equipment for steel pipe column

A technology for installing equipment and steel pipe columns, which can be used in infrastructure engineering, construction, building construction, etc., and can solve the problems of high safety risks for workers, high costs, and low positioning accuracy of steel pipe columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

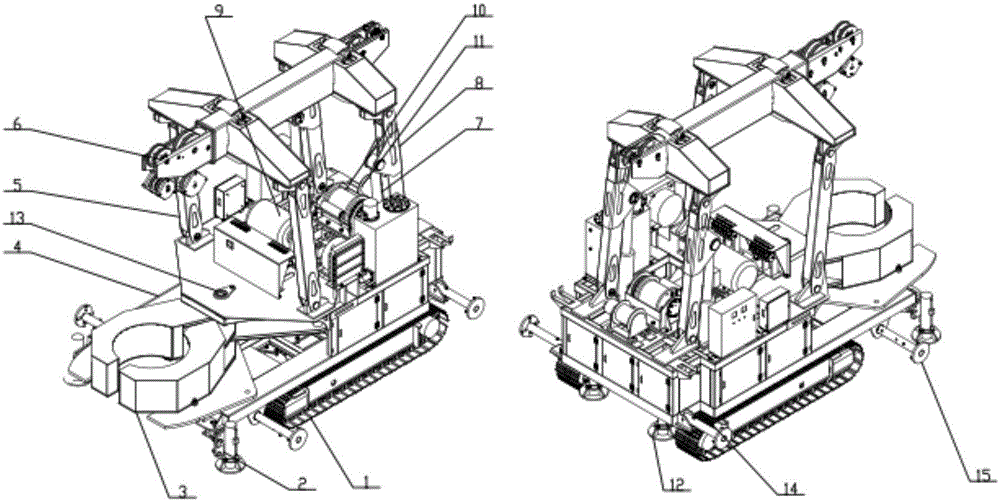

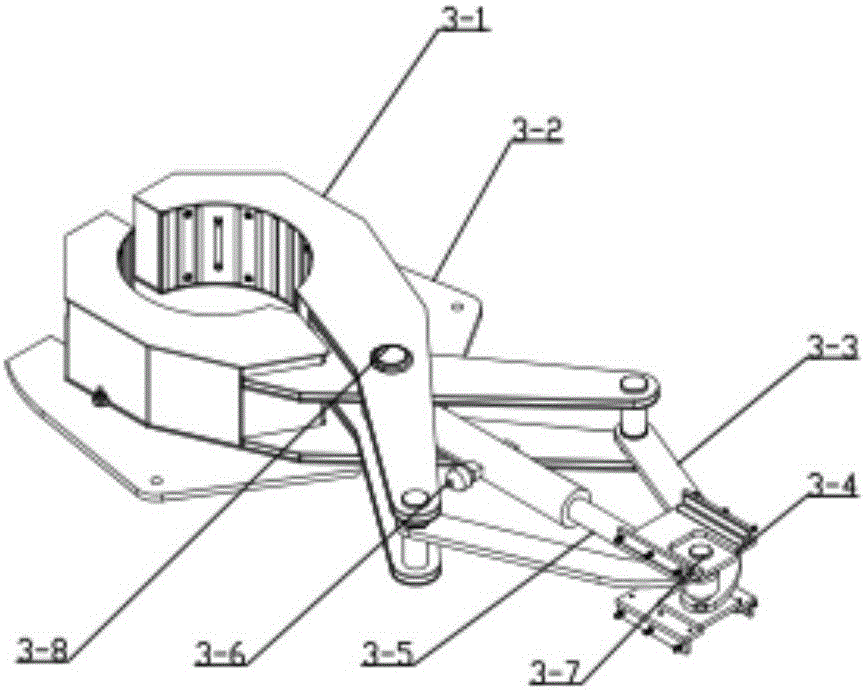

[0023] see figure 1, the chassis assembly 1 is connected to the upper vehicle assembly 4 through bolts, and the brake fixed upper plate 4-10 and the brake fixed lower plate 4-6 of the upper vehicle assembly 4 are connected to the brake assembly 3 through the brake fixed shaft 13 , the slider 3-4 in the brake assembly 3 slides between the upper slideway 4-4 and the glideway 4-7 in the boarding assembly 4; The luffing link lug 4-3 of the assembly 4 is connected by a pin, the pin hole on the front luffing link 5 is connected with the luffing link front wing 6-4 of the boom assembly 6 by a pin, and the rear The lower pin hole of the luffing link 8 is connected with the luffing link lug 4-3 of the upper vehicle assembly 4 through a pin shaft, and the upper pin hole of the rear luffing link 8 is connected with the luffing link of the boom assembly 6 The rear wing 6-3 is connected by a pin shaft; the cylinder body of the luffing cylinder 7 is connected with the luffing cylinder ear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com