Horizontal continuous electroplating production line and its production process

A technology of electroplating production line and production process, applied in the direction of plating tank, electrolytic components, electrolytic process, etc., to achieve the effect of reducing decomposition, reducing disturbance and avoiding mutual pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

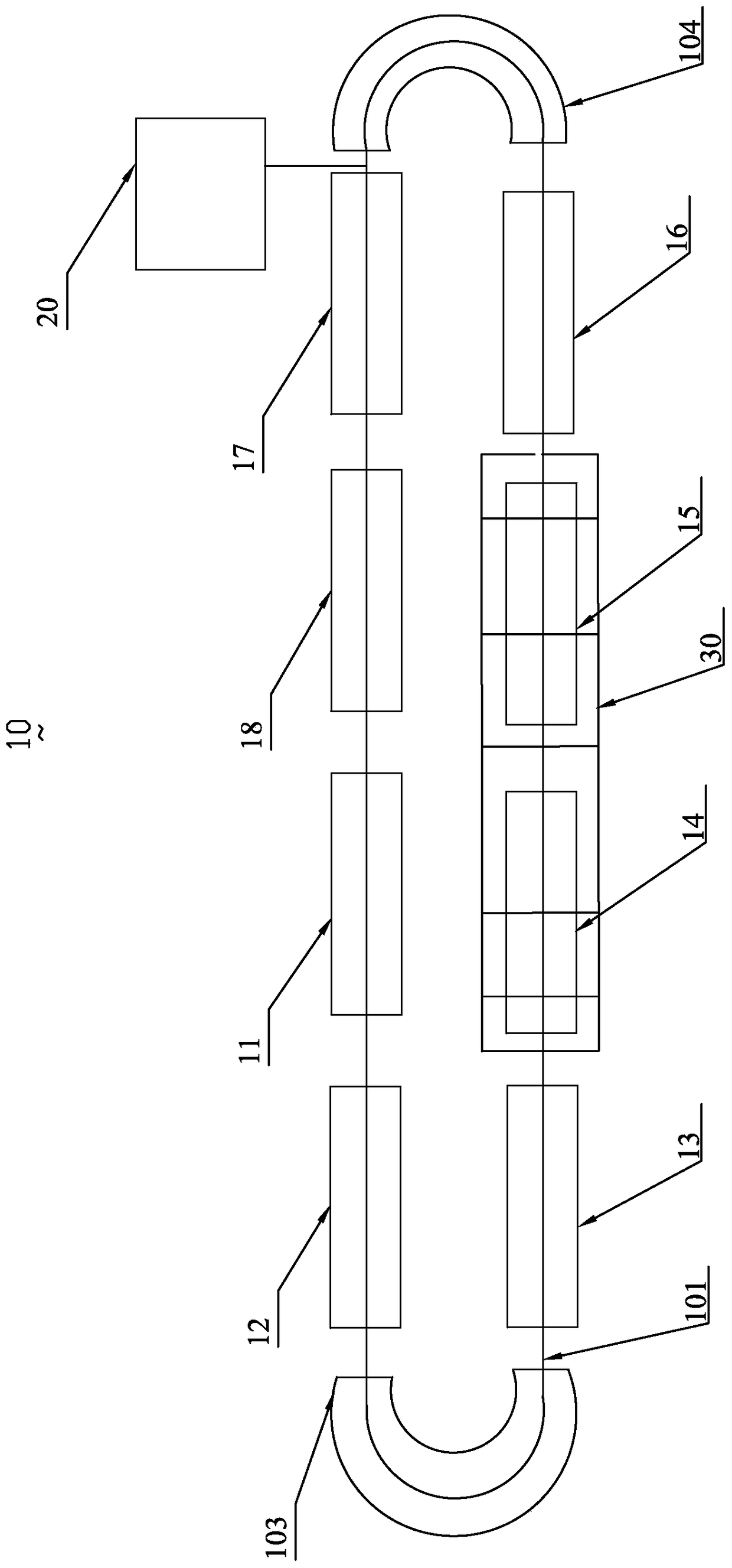

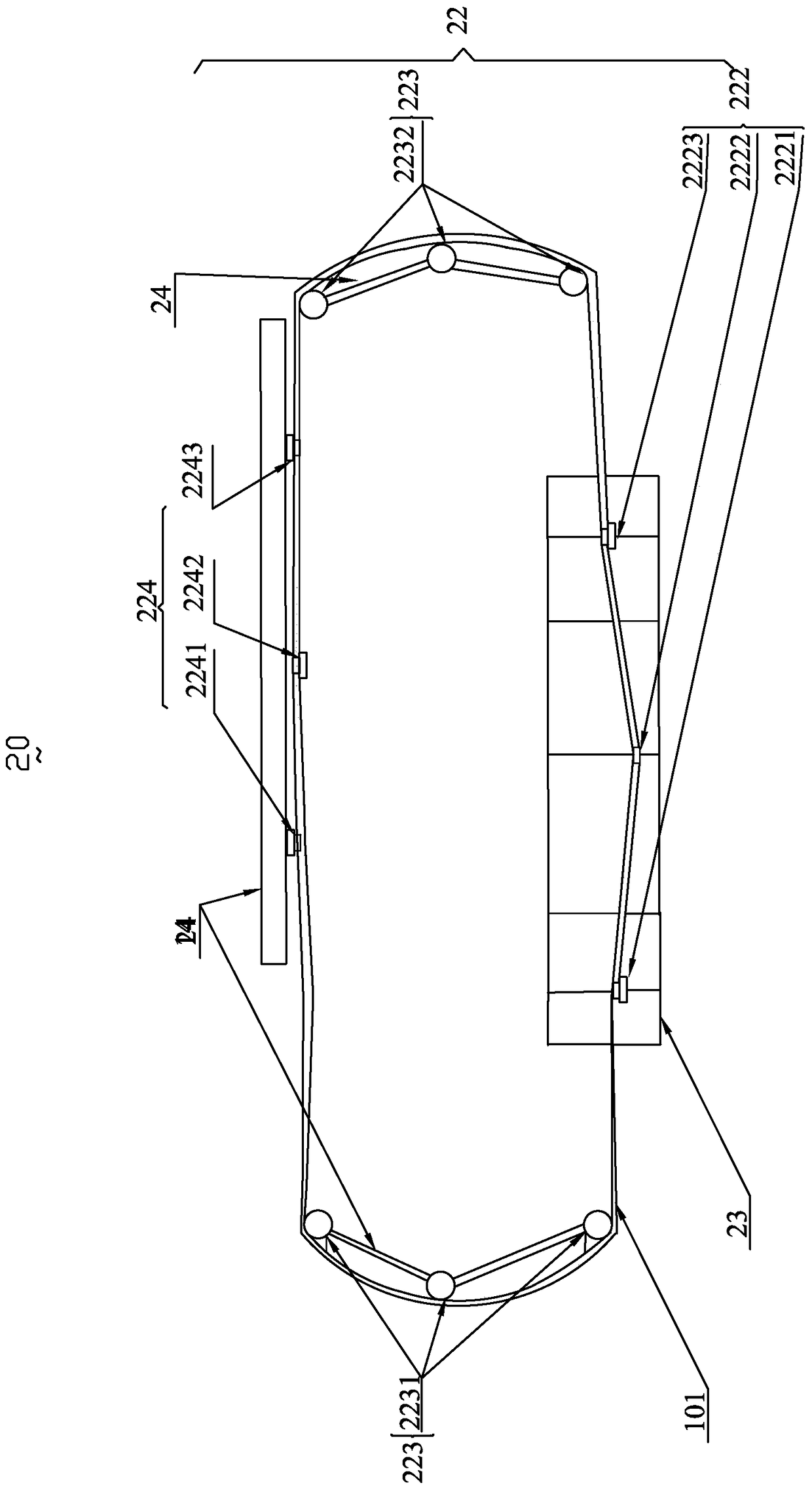

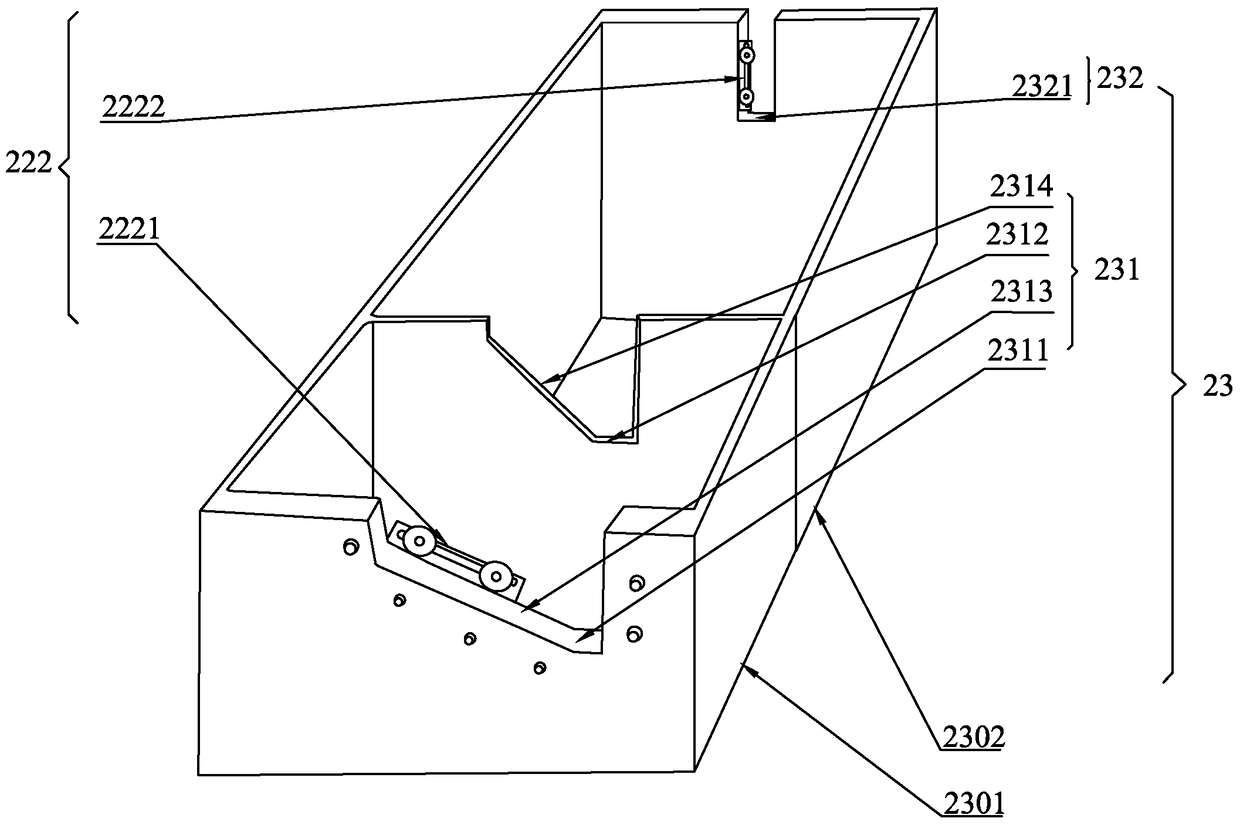

[0086] see Figure 11 , the second embodiment of the present invention provides a horizontal continuous electroplating production process, please refer to the appended Figure 1-10 , which includes the following steps:

[0087] Step S40, providing a horizontal continuous electroplating production line 10, the horizontal continuous electroplating production line 10 is consistent with the horizontal electroplating production line 10 provided in the first embodiment of the present invention, which includes a steel strip 101, a steel strip turning device 22, and the steel strip 101 is arranged in a closed Ring structure, the steel belt turning device 22 drives the steel belt 101 to circulate and close the circular motion, and successively pass through the hanging area 11, the degreasing area 12, the pre-treatment turning area 103, the impact nickel area 13, the sand nickel area 14, and the nickel-cobalt alloy area 15. After cleaning the sealing area 16, post-processing turning ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com