Method for improving strength and intercrystalline corrosion resisting performance of aluminum alloy

An intergranular corrosion, aluminum alloy technology, applied in the field of aluminum alloy material manufacturing, can solve the problems of low strength of 6000 series aluminum alloy, sensitivity to intergranular corrosion, affecting aircraft life and safety, etc., and achieve high extrusion deformation strengthening effect. Effect

Inactive Publication Date: 2017-01-11

张家港市丰乐汽车设备有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, so far, the proportion of 6000-series aluminum alloys used in aircraft manufacturing is significantly lower than that of 7000-series and 2000-series aluminum alloys

The primary reason for this phenomenon is the relatively low strength of 6000 series aluminum alloys.

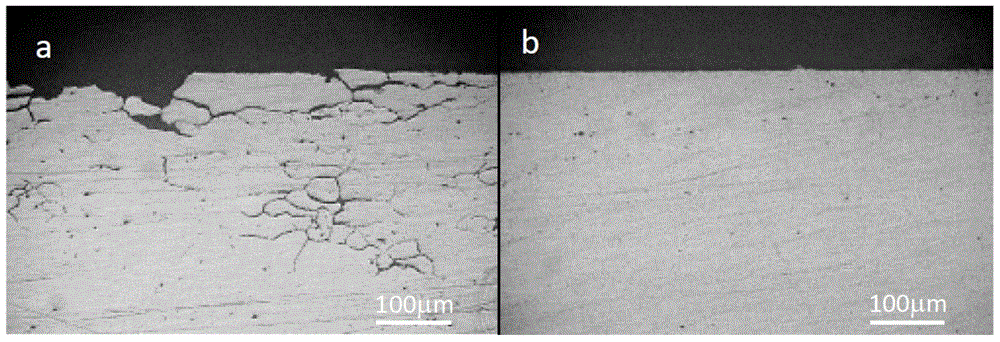

Although artificially aged to the peak state (T6), the strength of 6000-series aluminum alloys is still much lower than that of 7000-series and 2000-series aluminum alloys, which cannot reflect the advantages of weight reduction; at the same time, 6000-series aluminum alloys still have serious Inter-corrosion sensitivity, which seriously affects the life and safety of aircraft

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] The present invention is further illustrated by the following examples: According to the following examples, the present invention can be better understood. However, those skilled in the art can easily understand that the specific material ratios, process conditions and results described in the examples are only used to illustrate the present invention, and should not and will not limit the present invention described in the claims.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

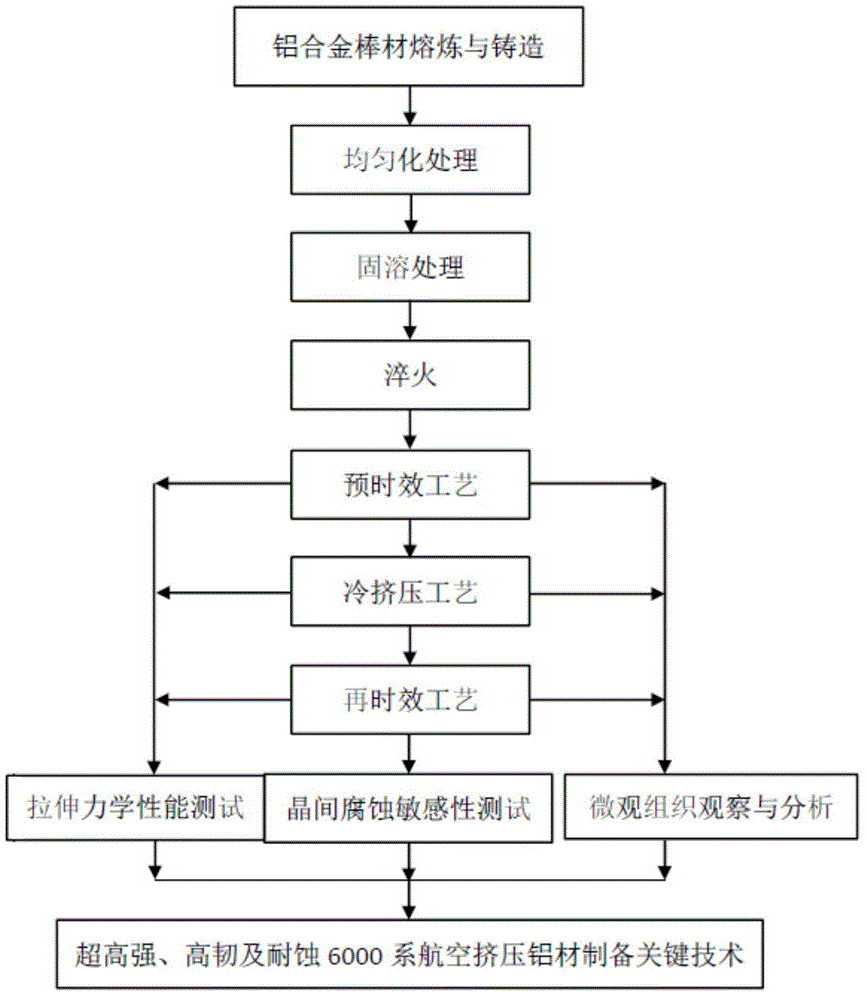

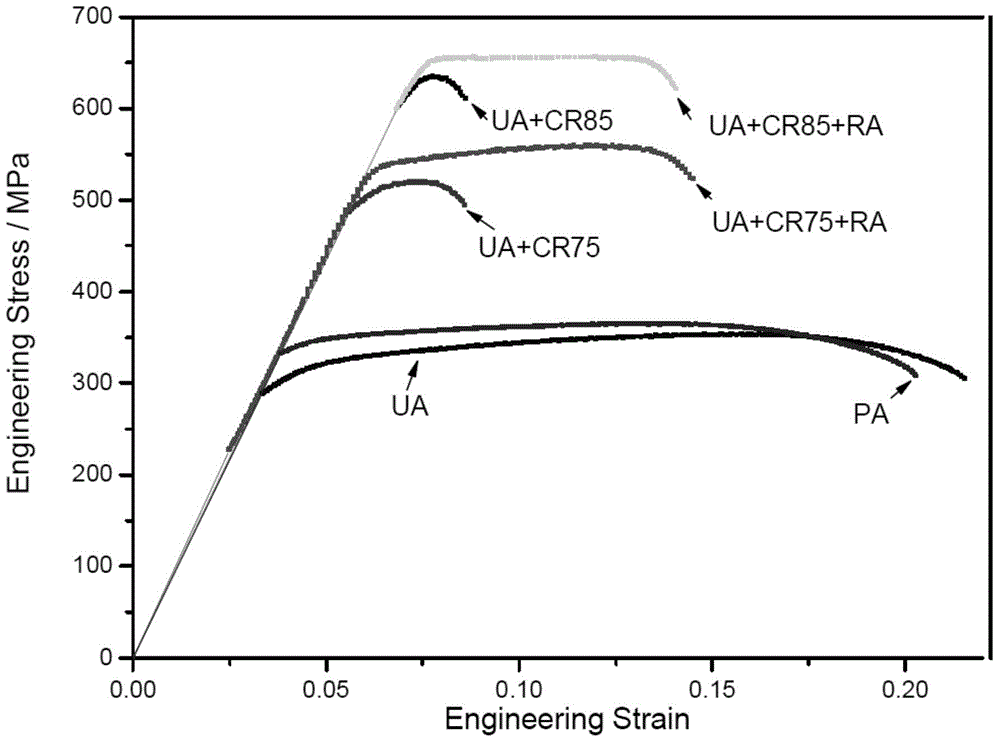

The invention discloses a method for improving the strength and intercrystalline corrosion resisting performance of an aluminum alloy. The 6061 aluminum alloy serves as a raw material, 550 DEG C / 1h solution treatment and water quenching, 180 DEG C / 2h under ageing, 75% rolling reduction cold rolling and 100 DEG C / 48 h low-temperature re-ageing are conducted, and the aluminum alloy with the high strength and intercrystalline corrosion resisting performance is obtained. The tensile strength of the aluminum alloy is 560 MPa, the yield strength of the aluminum alloy is 542 MPa, the elongation at break is 8.5%, and the average ductility is 7%.

Description

technical field [0001] The application belongs to the field of aluminum alloy material manufacturing, and in particular relates to a method for improving the strength and intergranular corrosion resistance of aluminum alloy. Background technique [0002] Age-hardening aluminum alloy has low density, high specific strength, good corrosion resistance and plastic formability, and is an important lightweight structural material widely used in aircraft manufacturing, mainly including ultra-high strength 7000 series Al-Zn-Mg-Cu alloy (500-700MPa), high-strength 2000 series Al-Cu-Mg alloy (400-500MPa) and medium-strength 6000 series Al-Mg-Si-Cu alloy (300-400MPa), the representative alloy grades are 7075, 2024 and 6056. Compared with the 7000 series and 2000 series aluminum alloys, although the 6000 series aluminum alloys have the advantages of low material density and cost, ingot formability, plastic processing performance, excellent surface treatment performance and low tendency...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22F1/043

Inventor 赵英

Owner 张家港市丰乐汽车设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com