Method for controlling outlet air temperature of direct-combustion hot blast stove

A technology of air outlet temperature and hot blast stove, which is applied in steel manufacturing technology, furnaces, blast furnaces, etc. It can solve problems such as differences in hot blast stove structure and control logic, and achieve the effects of stable air outlet temperature, energy saving, and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

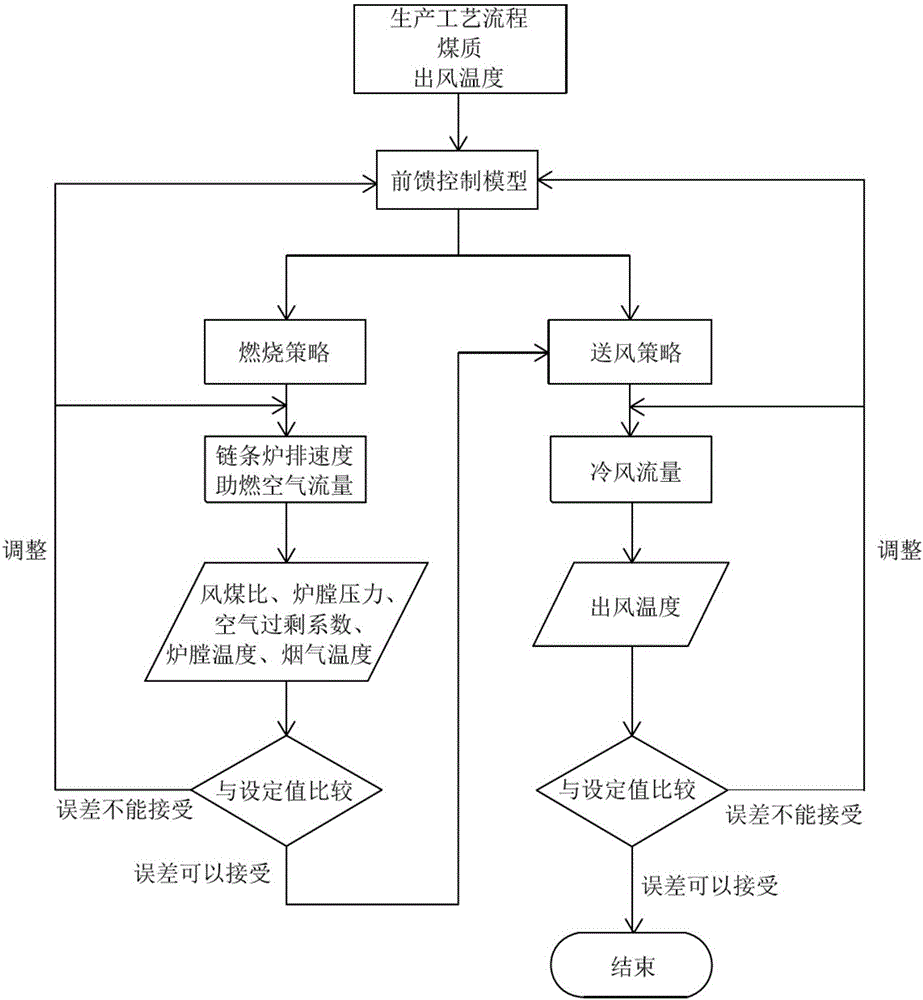

[0028] Please refer to figure 1 As shown, a method for controlling the outlet air temperature of a coal direct-fired hot blast stove adopts a combination of feedforward control and process control, including two stages of preliminary preparation and online operation, and is characterized in that:

[0029] The preparatory stage includes the following steps:

[0030] 1) Extract the historical operating data of the coal direct-fired hot blast stove, and use the applicable principles to identify and analyze the parameters involved in the system, specifically including the following steps:

[0031] ① Analyze the influence of different coal qualities on the combustion process in the combustion chamber, and find out the relationship between coal quality and air-to-coal ratio, where the air-to-coal ratio is determined by chain grate speed, coal thickness, and combustion-supporting air flow;

[0032] ② Find out the relationship between the air-to-coal ratio, the furnace temperature in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com