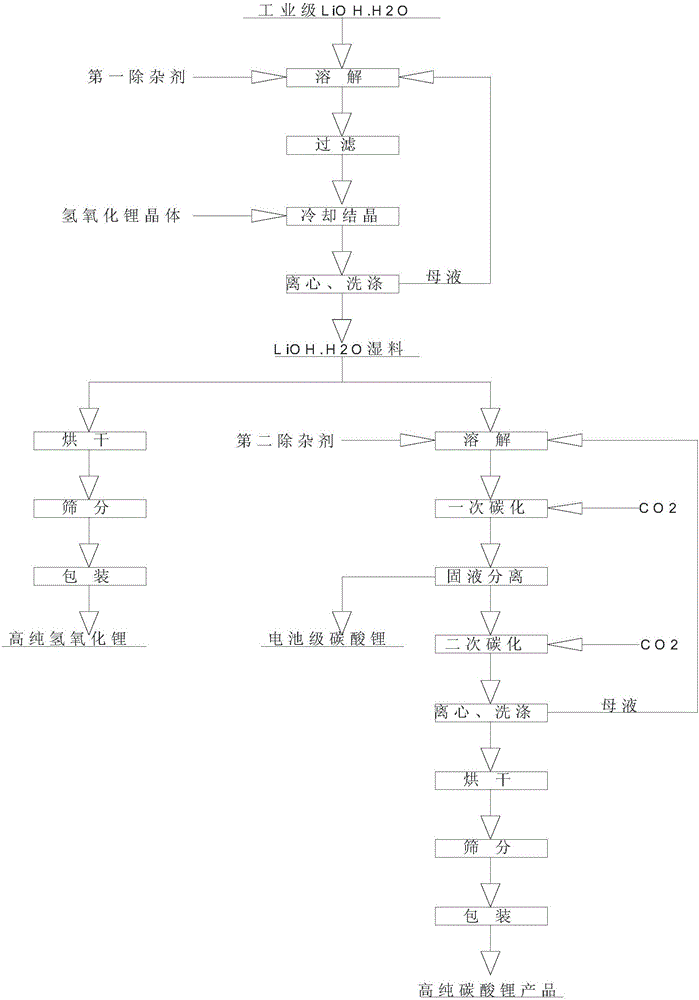

Method for composite production of high-purity lithium hydroxide monohydrate, high-purity lithium carbonate and battery grade lithium carbonate

A technology of lithium hydroxide monohydrate and high-purity lithium carbonate, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, carbonate preparations, etc., can solve the problems affecting yield, low reaction speed, and utilization rate Low-level problems, to achieve the effect of low equipment investment, low cost, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

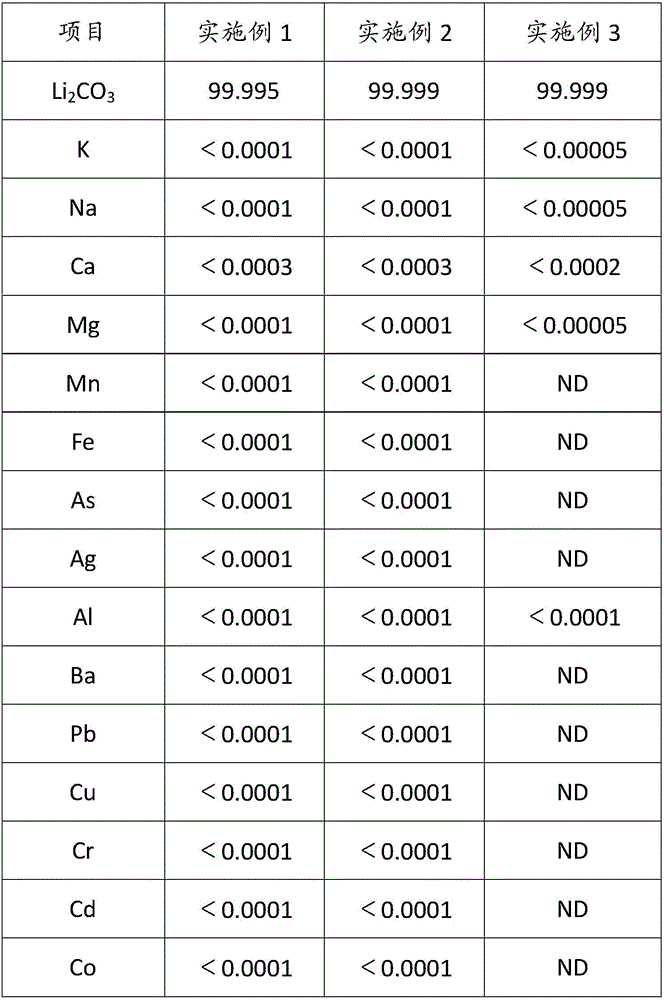

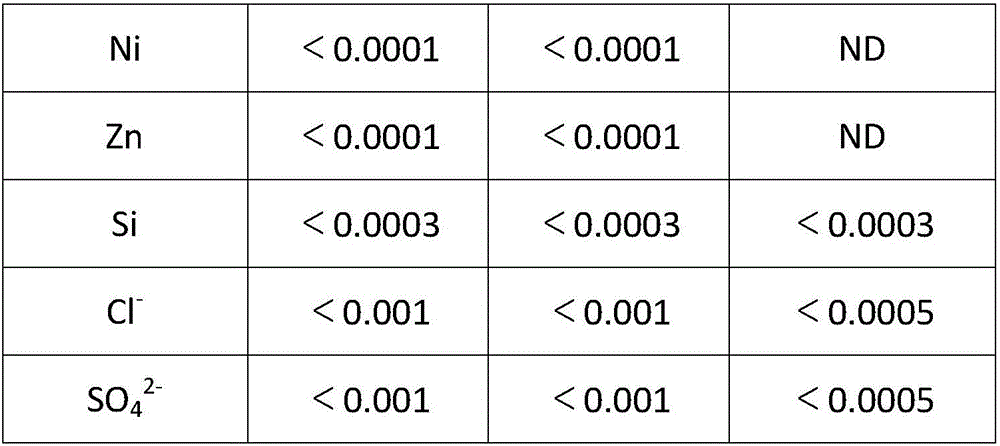

Examples

Embodiment 1

[0068] Dissolve industrial-grade lithium hydroxide monohydrate in deionized water at 80°C to prepare a first solution with a LiOH concentration of 160g / L; add 0.5% of lithium hydroxide input into the first solution prepared above The first impurity remover, oxalic acid, was incubated and reacted for 15 minutes, then filtered, the filtrate was pumped into the crystallizer, and high-purity lithium hydroxide monohydrate crystals with 10% lithium hydroxide mass were added, cooled and crystallized, and solid-liquid separation was carried out when the solution temperature dropped to 50°C , the obtained solid is rinsed with 15% pure water of lithium hydroxide mass to obtain high-purity lithium hydroxide monohydrate wet material and crystallization mother liquor; part of the high-purity lithium hydroxide monohydrate wet material is dried and sieved Finally, high-purity monohydrate lithium hydroxide product is obtained.

[0069] In a stainless steel carbonization reaction kettle, the h...

Embodiment 2

[0072] Dissolve industrial-grade lithium hydroxide monohydrate in deionized water at 90°C to prepare a first solution with a LiOH concentration of 165g / L; add 0.8% of the mass of lithium hydroxide to the first solution prepared above and wherein The first impurity remover with a mass ratio of oxalic acid to EDTA of 2:1, heat preservation reaction for 15 minutes and then filter, the filtrate enters the crystallizer, add high-purity lithium hydroxide monohydrate wet material with 20% lithium hydroxide mass, cool and crystallize, when the solution When the temperature drops to 45°C, solid-liquid separation is carried out, and the obtained solid is rinsed with 20% pure water of lithium hydroxide mass to obtain high-purity lithium hydroxide monohydrate wet material and crystallization mother liquor; high-purity lithium hydroxide monohydrate wet material After drying and sieving, a high-purity lithium hydroxide monohydrate product is obtained.

[0073] Dissolve the high-purity monoh...

Embodiment 3

[0076]Dissolve industrial-grade lithium hydroxide monohydrate in deionized water at 100°C to prepare a first solution with a LiOH concentration of 170g / L; add 1% of the mass of lithium hydroxide and lithium oxalate The first impurity remover with a mass ratio of 1:1 to EDTA was kept and reacted for 20 minutes, then filtered, the filtrate was pumped into a crystallizer, and high-purity lithium hydroxide monohydrate wet material with a mass of lithium hydroxide of 30% was added, cooled and crystallized. When the temperature of the solution drops to 40°C, solid-liquid separation is carried out and the resulting solid is rinsed with 30% pure water of lithium hydroxide mass to obtain high-purity monohydrate lithium hydroxide wet material and crystallization mother liquor; high-purity monohydrate hydrogen Lithium oxide wet material is dried and sieved to obtain high-purity lithium hydroxide monohydrate product.

[0077] Dissolve the high-purity lithium hydroxide monohydrate wet mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com