Method for preparing graphene quantum dot from asphalt

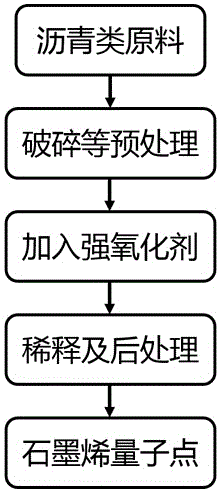

A technology of graphene quantum dots and pitch, which is applied in new preparation fields, can solve problems such as unfavorable large-scale production, difficulty in obtaining precursors, cumbersome preparation process, etc., and achieve the effect of reducing preparation difficulty, good water solubility, and simple processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 0.5 g NaNO 3 , 4 g KMnO 4 Added to 35 mL concentrated H 2 SO 4 Stirring and mixing for 30 min is worth the oxidant mixed solution. Simultaneously mix 1 g of mesophase pitch powder with 5 mL of concentrated H 2 SO 4 Add them together to a 100 mL three-neck flask and wait for processing.

[0032] After 30 min, the oxidant mixture solution was added dropwise into the three-necked flask at a rate of 60 d / min under an ice-bath environment using an atmospheric separatory funnel, and stirring was started.

[0033] After 35 min, the temperature of the water bath was increased to 35 °C, and the oxidation reaction was continued to stir for 6 h to obtain the product solution.

[0034] Then the reaction solution was poured into 250 mL deionized water, and H 2 o 2 After reaching 400 mL, stir for 24 h to remove unreacted oxidant. The above solution was centrifuged at 10,000 rpm for 5 min to obtain the supernatant and then dialyzed to obtain the graphene quantum dot solution....

Embodiment 2

[0036] Concentrated H 2 SO 4 with H 2 o 2 (30%) were mixed and stirred for 30 min at a volume ratio of 7:3 to obtain a mixed solution of oxidant. At the same time, 1 g of mesophase pitch powder was added to a 100 mL three-neck flask for processing.

[0037] After 30 min, 40 mL of the oxidant mixed solution was added dropwise into the three-necked flask at a rate of 60 d / min under an ice-bath environment using an atmospheric separatory funnel, and stirring was started. React in ice bath for 24 h.

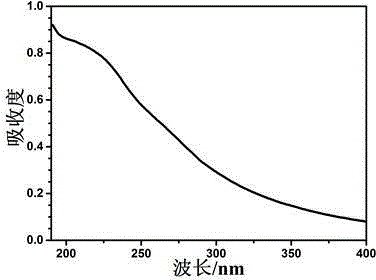

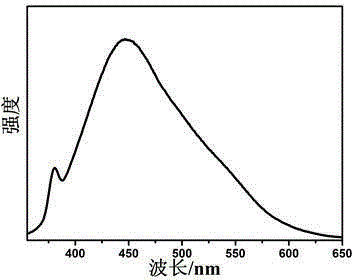

[0038] Then the reaction solution was poured into 300 mL deionized water and stirred for 24 h. The above solution was centrifuged at 10,000 rpm for 5 min to obtain the supernatant and then dialyzed to obtain the graphene quantum dot solution. Its UV absorption and fluorescence emission spectra are shown in Figure 4 with Figure 5 shown.

Embodiment 3

[0040] Mix 1 g of mesophase pitch powder, 30 mL of concentrated H 2 SO 4 and 10 mL concentrated HNO 3 Added into a three-necked flask, stirred and reacted at 85 °C for 24 h.

[0041] Then the reaction solution was poured into 250 mL deionized water, and H 2 o 2 After reaching 400 mL, stir for 24 h to remove unreacted oxidant. The above solution was centrifuged at 10,000 rpm for 5 min to obtain the supernatant and then dialyzed to obtain the graphene quantum dot solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com