Electric multifunctional tea and material packaging machine based on numerical control technology

A multi-functional, packaging machine technology, applied in packaging, transportation packaging, packaging protection and other directions, can solve the problems of pollution, low reliability, hidden safety hazards, etc., to achieve the effect of good continuity and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

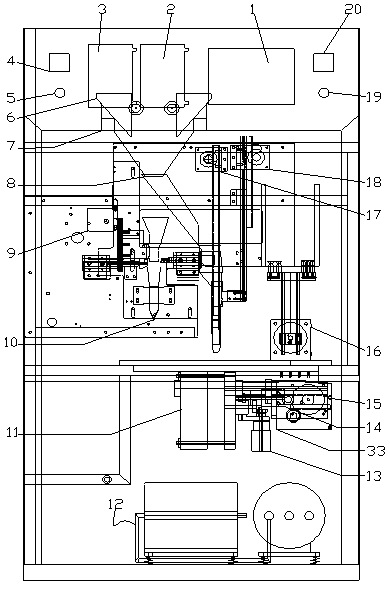

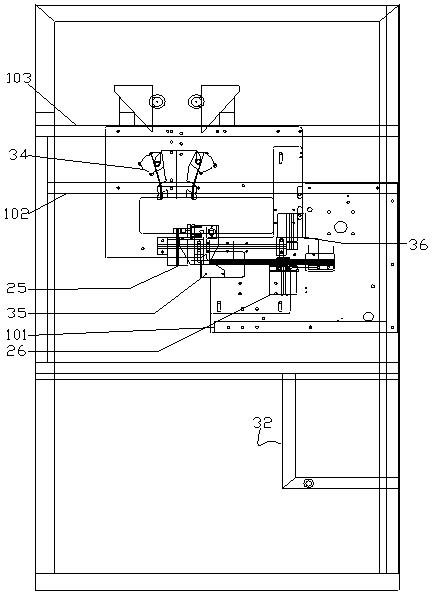

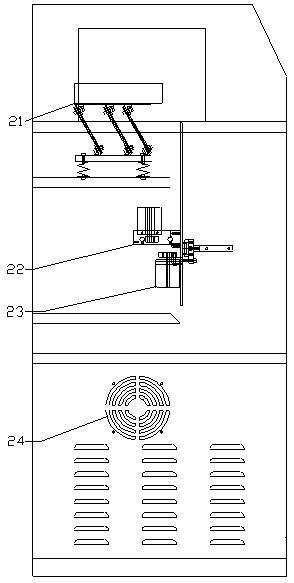

[0062] Such as Figure 1-20 As shown, it shows a specific embodiment of the present invention. As shown in the figure, the electric multifunctional tea packaging machine based on numerical control technology disclosed by the present invention includes a bracket on which a feeding component is arranged for packaging tea to The inner film-packing component of the inner film, the outer package component for packaging tea to the outer package, and the vacuum chamber mechanism 11 for packaging the outer package;

[0063] The inner membrane assembly includes an inner membrane drive assembly, a front and back inner membrane sealing and cutting inner membrane mechanism 23, and a DC motor pulling the inner membrane mechanism 9;

[0064] The inner membrane pulling mechanism of the DC motor is located directly below the outlet of the feeding assembly; the inner membrane driving assembly includes an inner membrane pulling stepper motor mechanism; the inner membrane is driven to feed through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com