Unscrewing mold stripping mechanism

A demoulding mechanism and undercut technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of increasing the production cost of product parts, increasing the overall size of the mold, and reducing the service life of the mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

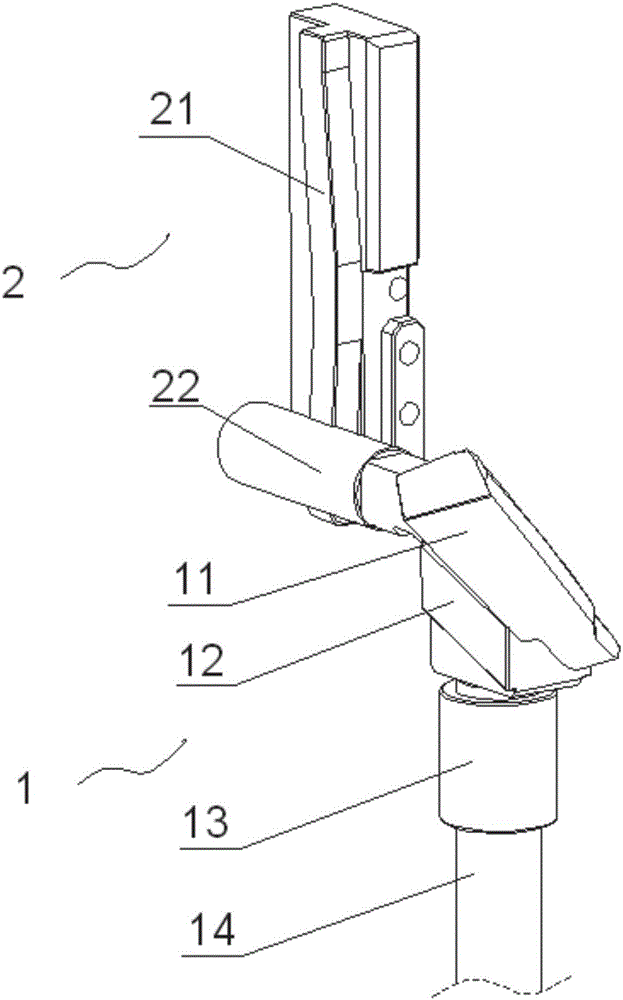

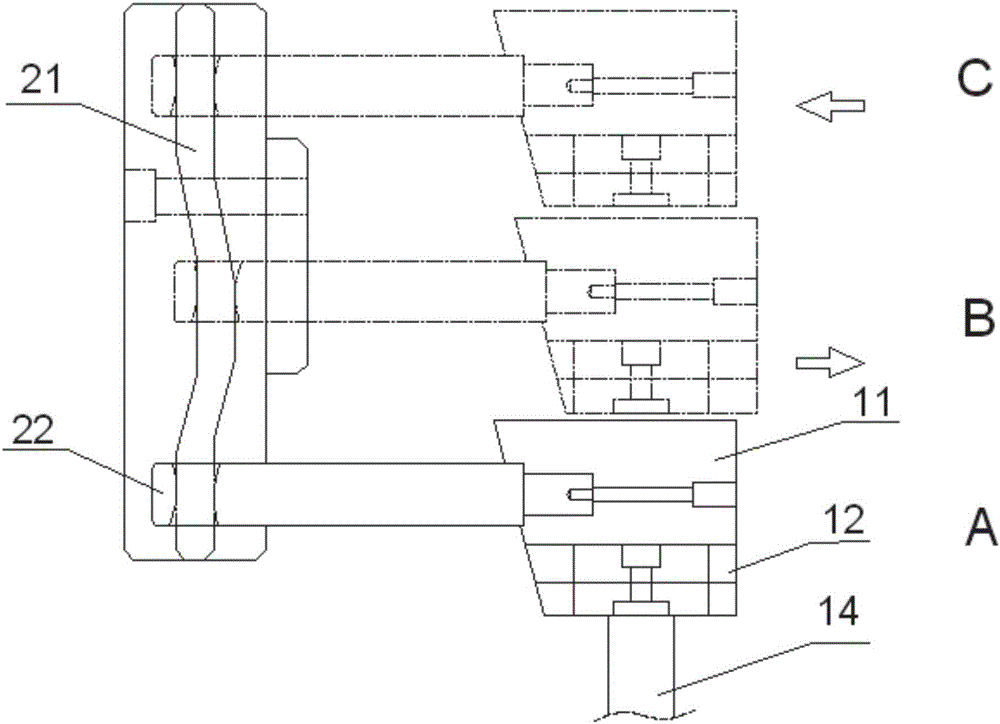

[0022] Embodiment: This embodiment provides a specific embodiment of an undercut demoulding mechanism, which can be used for demolding some products with relatively complex structures, such as the demoulding of automobile bumpers. Because when designing a car bumper, not only its mechanical properties during use must be considered, but also its aesthetic appearance. However, a car bumper is relatively large and has a relatively complicated structure, so it is difficult to demould, especially when When the undercut surface is released from the mold, it is easy to cause damage to the appearance.

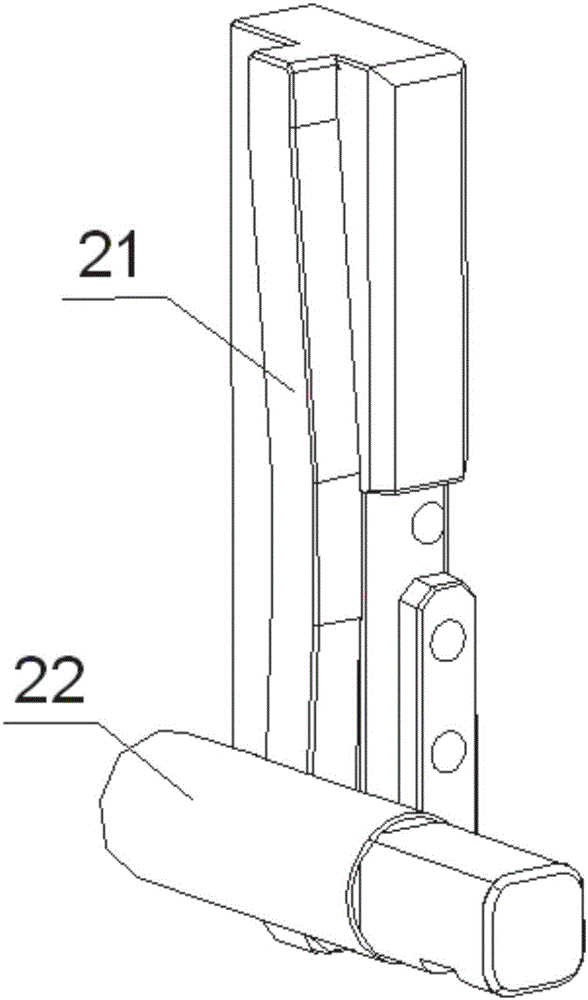

[0023] Such as figure 1 As shown, the undercut demoulding mechanism provided in this embodiment includes an ejection part 1 and an auxiliary guide part 2 mated with the ejection part 1 . When the automobile bumper is demolded, the ejection part 1 and the auxiliary guide part 2 cooperate with each other to finally complete the demoulding of the product.

[0024] Specifically, the ejec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com