Positioning system and method for punching of bolt holes in root portion of wind turbine blade

A technology of wind power blades and positioning system, applied in metal processing and other directions, can solve problems such as unfavorable blade weight control, take up a lot of time, reduce blade production efficiency, etc. The effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

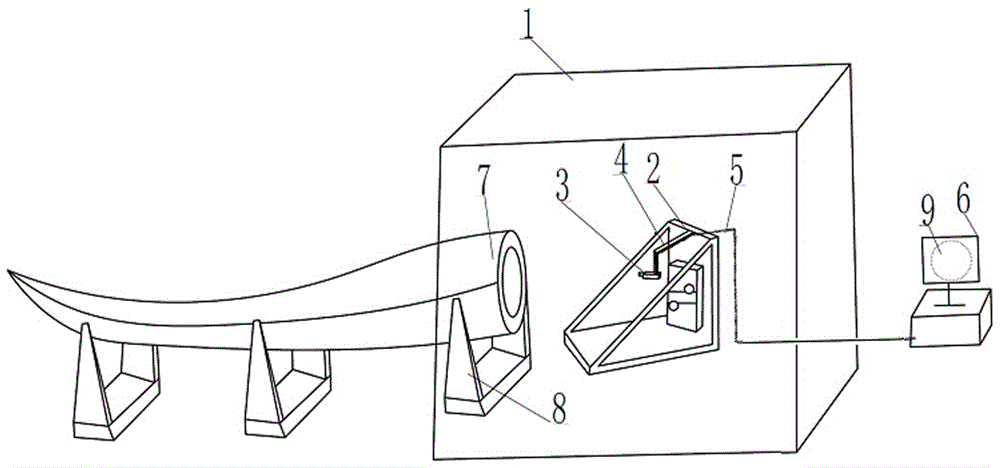

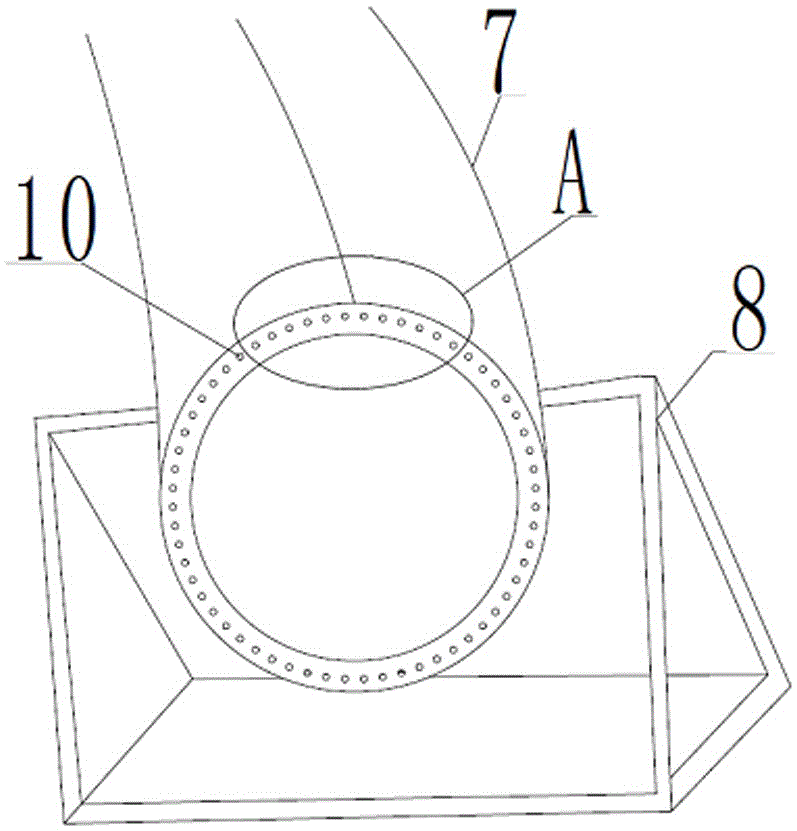

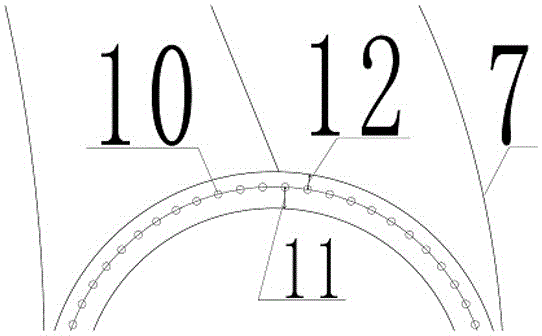

[0023] As shown in the figure: a positioning system for punching bolt holes at the root of wind power blades, including a computer 6, an imaging room 1, a root adjustment bracket 8, an optical imager 3, an imager bracket 4 and a punching hole set in the imaging room 1 The equipment bracket 2, the surroundings of the imaging chamber 1 are made up of opaque partitions, one of which is provided with a through hole for the root of the wind power blade 7 and the root adjustment bracket 8 to be inserted into the imaging chamber 1, so that the imaging chamber 1 Surrounding the punching equipment and the root of the wind turbine blade 7, the root adjustment bracket 8 is used to adjust the vertical and horizontal positions of the root of the wind turbine blade 7;

[0024] The optical imager 3 is fixedly arranged on one end of the imager support 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com