Laser vision guided automatic welding track tracking system and method

A vision-guided and automatic tracking technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, poor versatility, and low flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

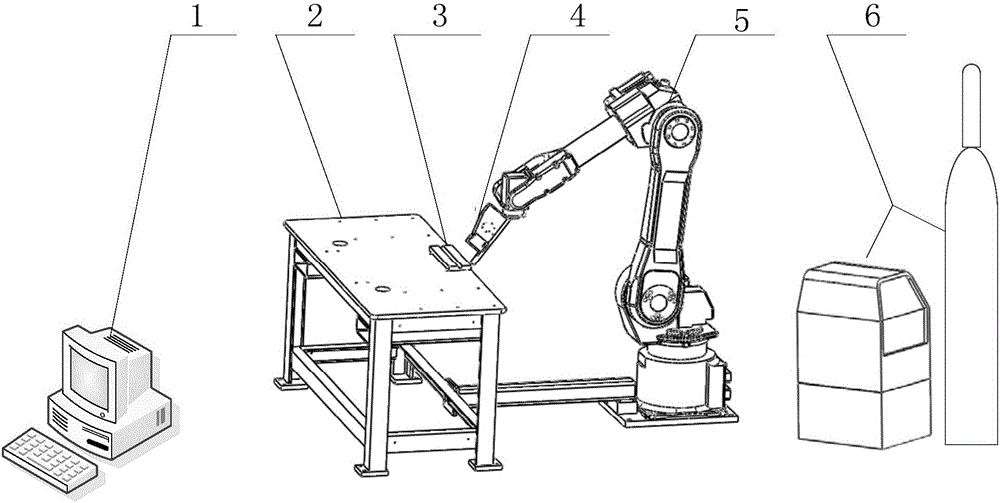

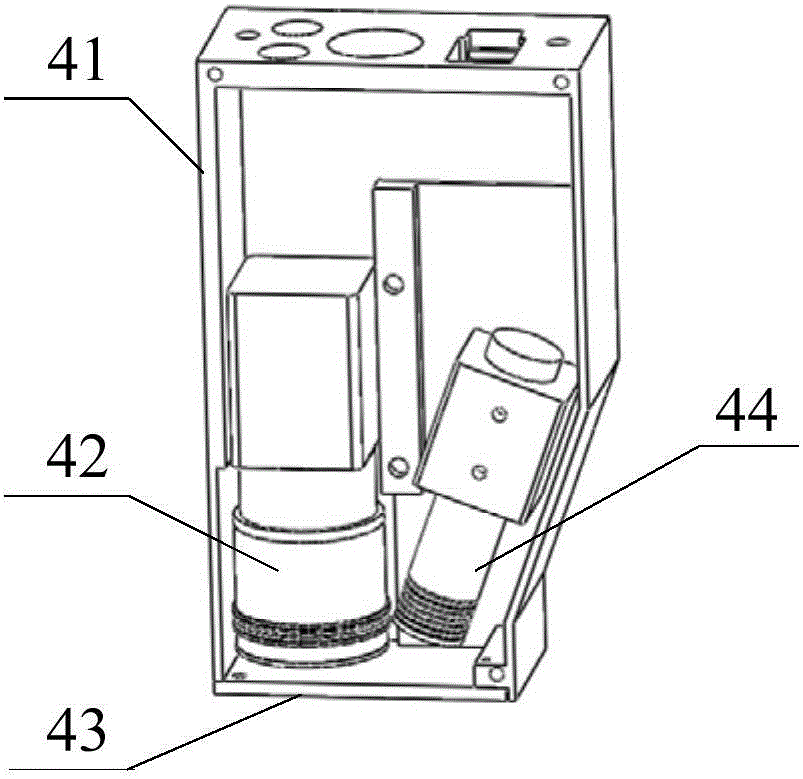

[0068] like figure 1 As shown, a laser vision-guided welding trajectory automatic tracking system includes an embedded industrial computer 1 with an image processing device, a laser vision sensor 4, a welding robot 5, supporting welding equipment 6 and a workpiece clamping workbench 2, and a workpiece 3 Fixed on the clamping workbench 2, the laser vision sensor 4 is installed on the welding torch in advance in the welding direction through the laser sensor fixing element, and the welding torch is installed on the end flange of the welding robot 5 through the welding torch fixing element. The sensor 4 and the welding torch change its position in space through the movement of each axis of the welding robot 5. The supporting welding equipment 6 provides energy and materials for welding, and the embedded industrial computer 1 is connected with the laser vision sensor 4. Based on the image recognition and tracking of objects acquired by the laser vision sensor 4 and the accurate de...

Embodiment 2

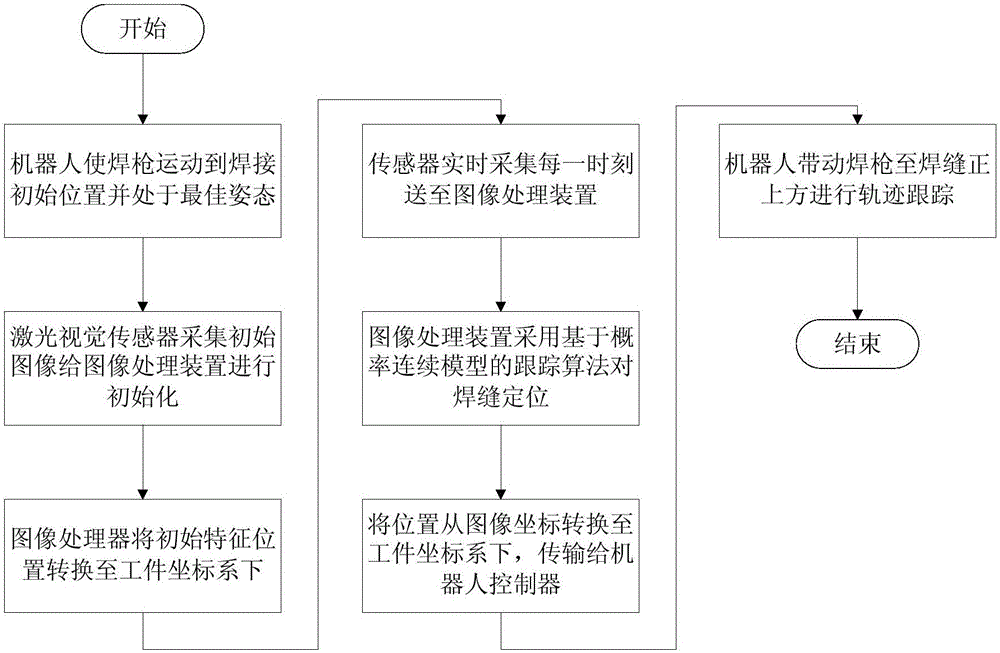

[0074] like image 3 Shown, a kind of welding track automatic tracking method based on the laser vision guidance of described system, comprises steps:

[0075] S1. Adjust the spatial position and posture of the welding robot 5 so that the welding gun with the fixed laser vision sensor 4 is in the initial welding position, and the laser line is within the field of view of the camera 42, and it is also necessary to ensure that during the continuous automatic welding seam recognition and tracking process, The workpiece will not interfere with the laser vision sensor 4;

[0076] S3, before the welding starts, the camera 42 in the laser vision sensor 4 first collects the characteristic fringe image and sends it to the image processing device, and performs initialization detection and positioning by calling the library function of the Halcon software to obtain the starting position of the weld seam;

[0077] S4, after the welding starts, the camera 42 of the laser vision sensor 4 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com