Wet-type permanent magnet belt high-intensity magnetic-field magnetic separator

A technology of strong magnetic field and magnetic separator, which is applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem that the weak magnetic mineral separation index is not as good as that of the electromagnetic high gradient magnetic separator, the dry separation has large dust, Difficulty in large-scale application and other problems, to achieve the effect of saving equipment space, saving manufacturing costs, and uniform ore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention clearer, the device will be described in detail below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

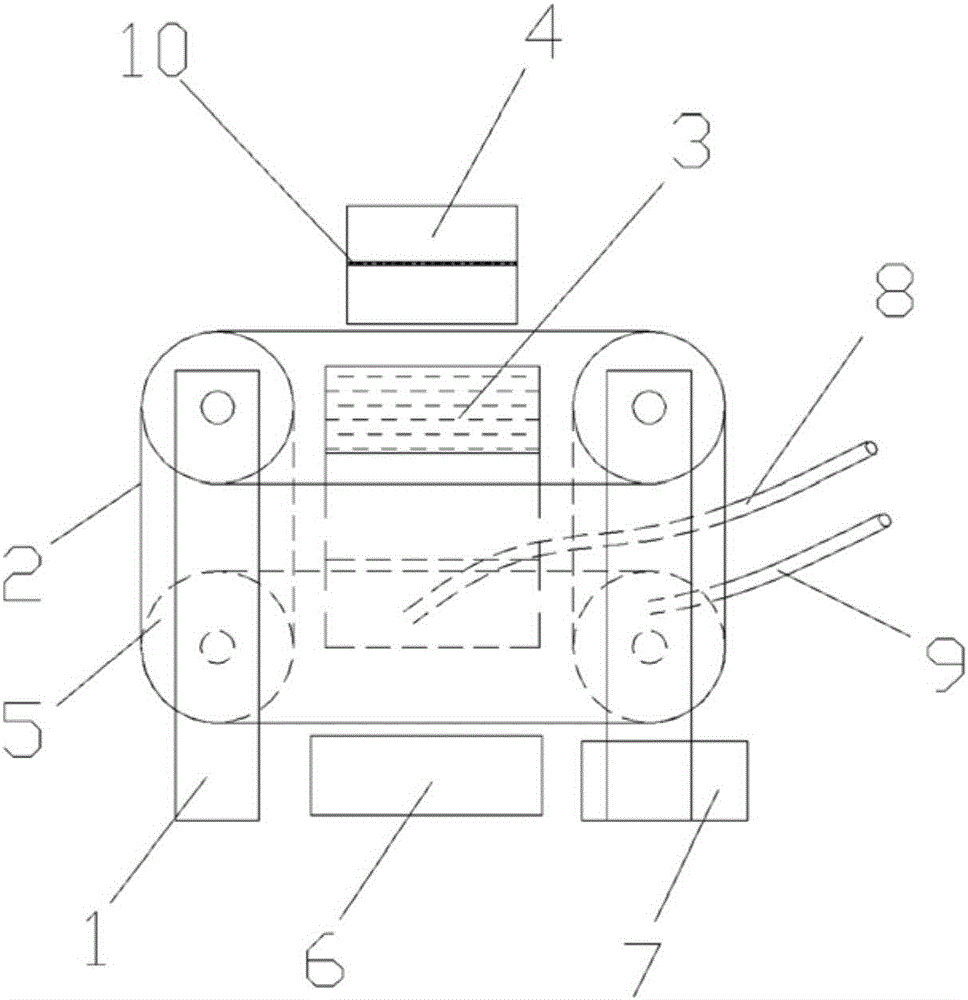

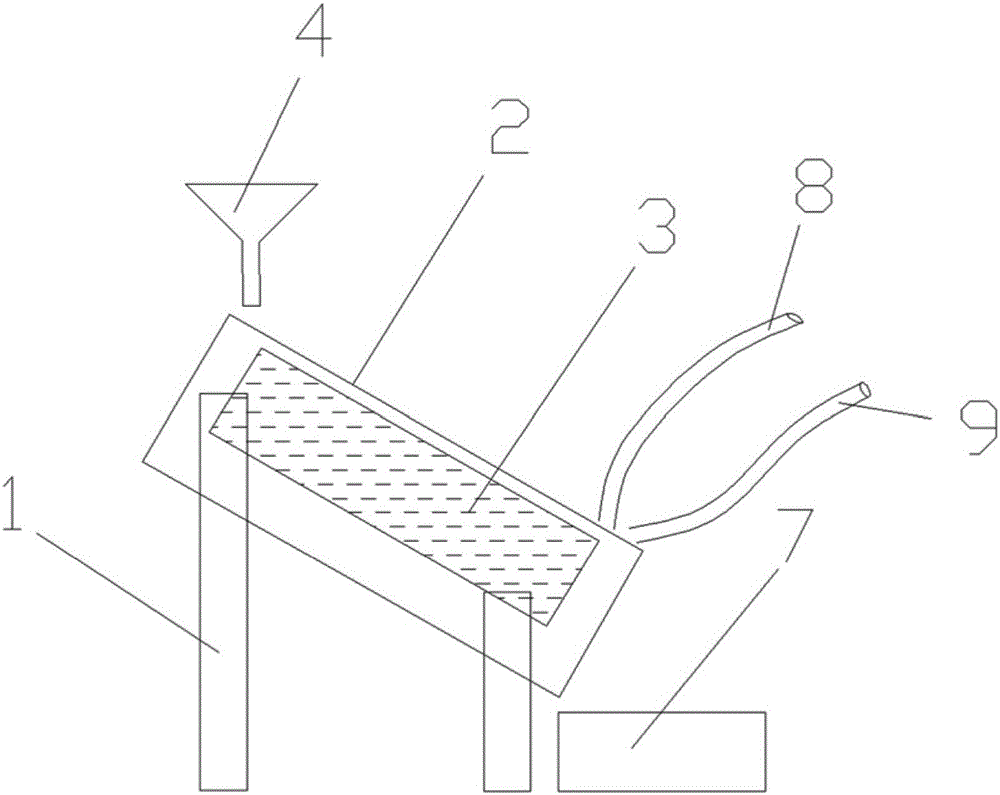

[0016] Such as figure 1 and figure 2 As shown, a kind of wet type permanent magnetic tape type high magnetic field magnetic separator provided by the present invention comprises frame 1, on frame 1 obliquely connects sorting plate 2, and sorting plate 2 is non-magnetic stainless steel, and it not only magnetic The resistance is small and wear-resistant, and the production cost is low. The inclination angle of the sorting plate 2 is 0-30°. In this solution, it is preferably 8°, 10°, 15°, 18°, 20°, 25° and 28°. Adjust and connect the magnetic system 3 in the sorting plate 2, the width of the sorting plate 2 is greater than the magnetic system 3, the magnetic pole surface of the magnetic syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com