Negative-pressure suction type electronic cigarette atomizing core structure

A technology of electronic smog and atomizing core, which is applied in the direction of smoker’s supplies, tobacco, application, etc. It can solve the problems of affecting cleaning and feeling, easy to scald the mouth of smokers, and reduce the service life of atomizing core, so as to prevent excessive liquid intake Liquid leakage, avoiding the effect of insufficient liquid supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

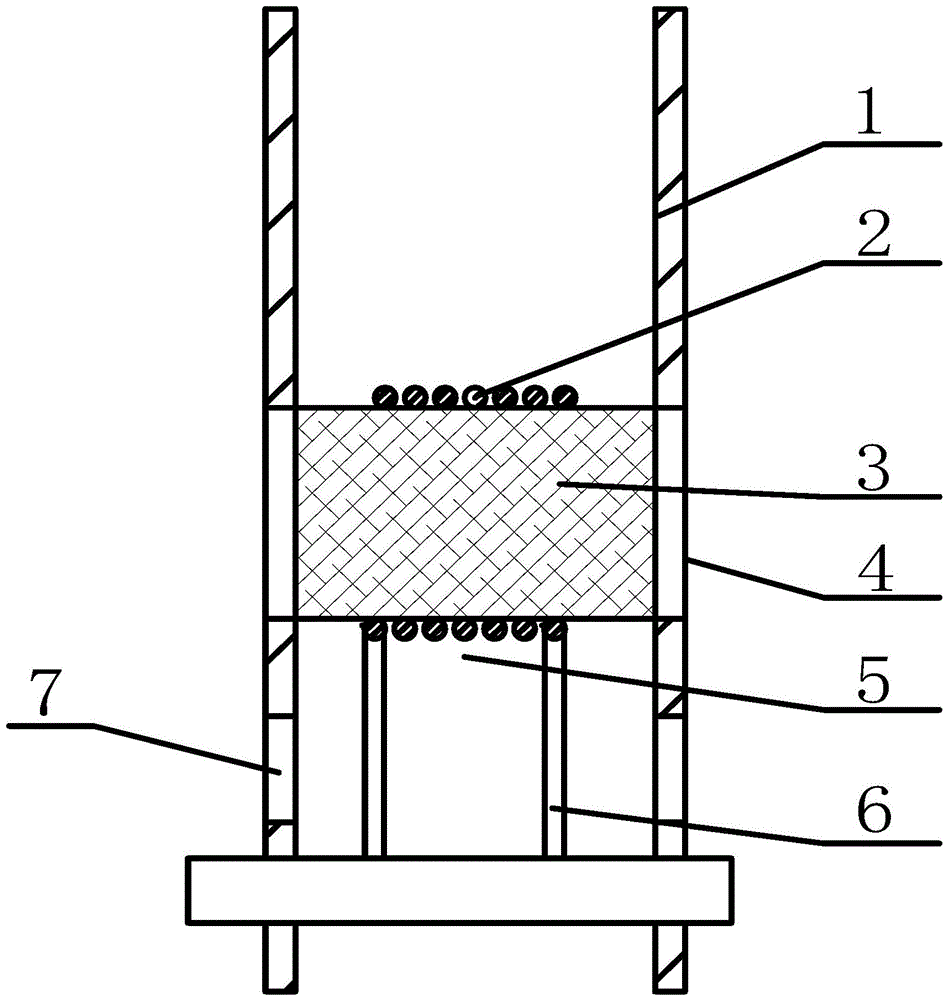

[0025] Such as figure 2 As shown, it is the negative pressure suction type electronic cigarette atomizing core structure of the present invention. The atomizing core includes a cylindrical atomizing core shell 1, and an electric heating wire 2 is arranged inside the atomizing core shell. The electric heating wire 2 It is arranged in a spiral shape, and the liquid-conducting fiber cotton 3 is arranged inside the spiral-shaped electric heating wire 2, and the atomizing core shell 1 is set as an inwardly protruding annular belt at a position corresponding to the liquid-conducting fiber cotton 3, due to The inner protrusion reduces the internal cross-sectional area, and here becomes the throat 8, that is to say, this is the throat mentioned in the Venturi principle. Offer liquid inlet 4 at the housing position of this throat 8, the shape of this liquid inlet 4 is circular opening (as image 3 shown), but its opening area is less than the cross-sectional area of the liquid-guid...

Embodiment 2

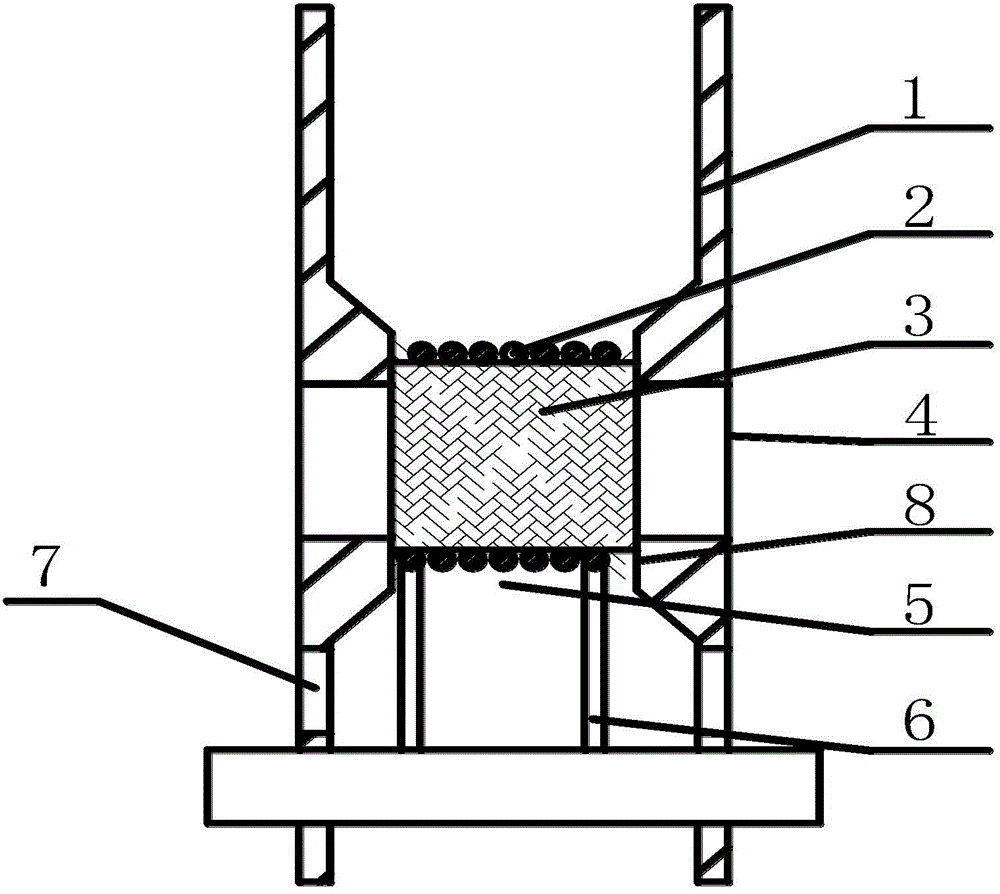

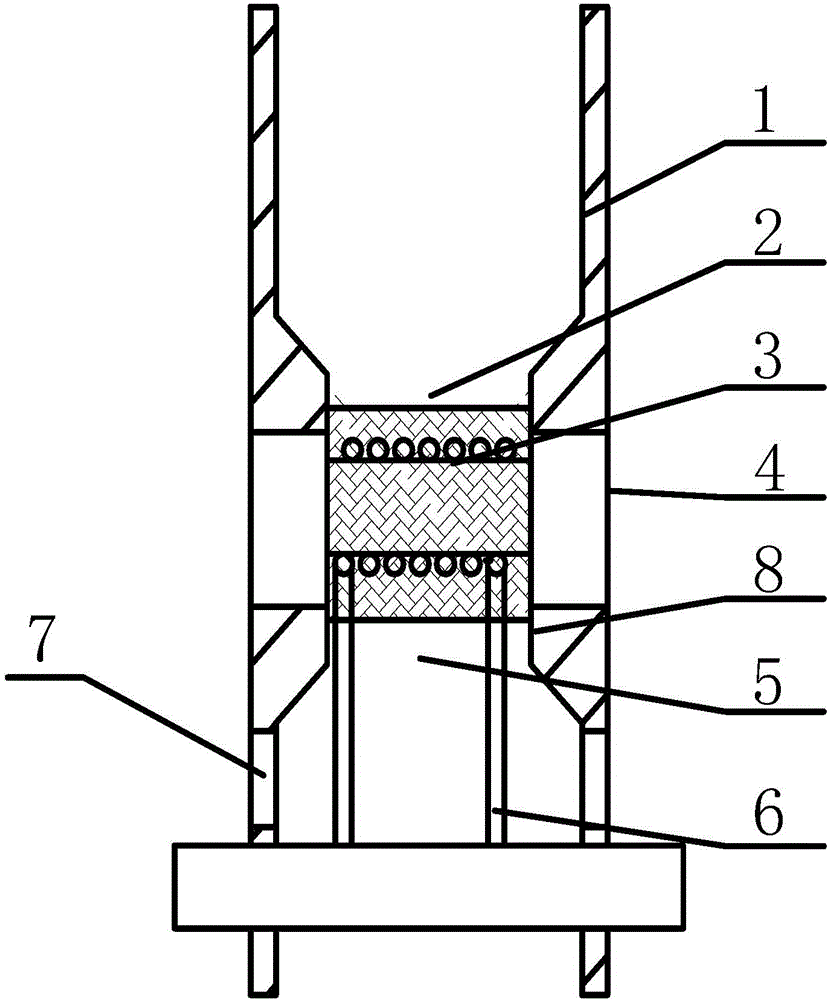

[0030] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that in order to make better use of the heat generated by the heating wire 2 to atomize the e-liquid more quickly, the inside and outside of the heating wire are equipped with liquid guides Fiber cotton3. Such as image 3 In the state shown, in addition to setting rope-shaped liquid-conducting fiber cotton inside the spiral-shaped heating wire, the outer periphery of the heating wire 2 is also provided with coated liquid-conducting fiber cotton.

[0031] At the same time, in order to prevent the seepage and leakage of the e-cigarette liquid when it is not inhaled, the shape of the liquid inlet 4 is further changed. As shown in 5, the liquid inlet 4 is set in a mesh shape, so that the e-cigarette liquid With a certain surface tension, a layer of tension film can be formed in a smaller mesh under normal pressure, instead of directly penetrating into the liquid-conducting fiber c...

Embodiment 3

[0033] The difference between this embodiment and embodiment 2 is that the screen-shaped liquid inlet hole is set as a grid-shaped liquid inlet hole, such as Image 6 The shown array of strip-shaped grid holes forms liquid inlet holes, and can also form a tension film, and meanwhile, the grid holes themselves can have a larger area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com