Special track conveying device for poultry processing assembly line

A conveying device and assembly line technology, applied in poultry transfer/conveyor, poultry processing, processed meat, etc., can solve the problem of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0015] This embodiment provides a scalding and plucking line dedicated to slaughtering poultry, and the present invention is used as a track conveying device.

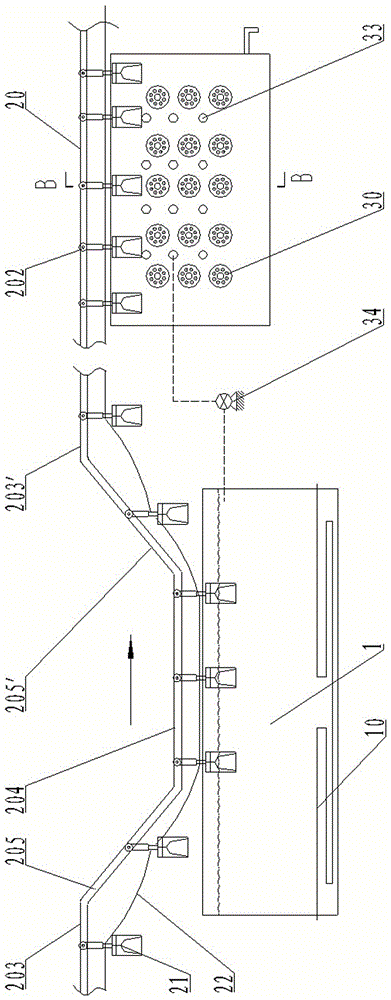

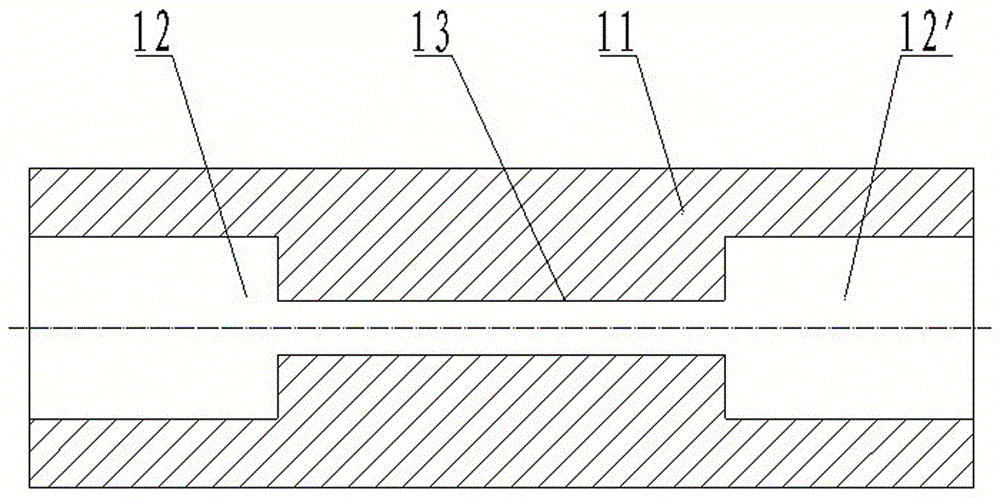

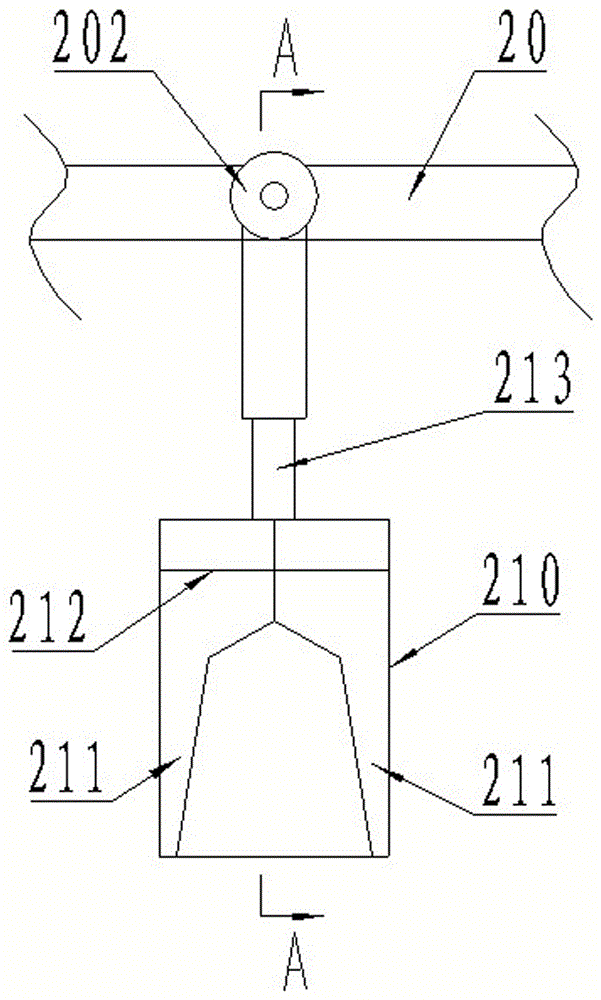

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the scalding and plucking line dedicated to slaughtering poultry in this embodiment includes a boiling water scalding device and a plucking device, and also includes a track 20 connecting the boiling water scalding device and the plucking device; the boiling water scalding device The device includes a boiling pool 1, a heating coil 10 is arranged in the boiling pool 1, a plurality of poultry racks 21 are movably arranged on the track 20, and a plurality of poultry racks 21 are driven along the track 20. Walking transmission belt 22; the plucking device includes a box body 3, the two ends of the box body 3 are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com