Loudspeaker for reducing vibration wave of vibrating diaphragm

A loudspeaker and vibration technology, applied in the direction of sensors, electrical components, etc., can solve problems such as large-amplitude bad residual vibration, improved speaker design, and affecting the sound quality of the speaker, so as to reduce the generation of residual vibration and improve the sound quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

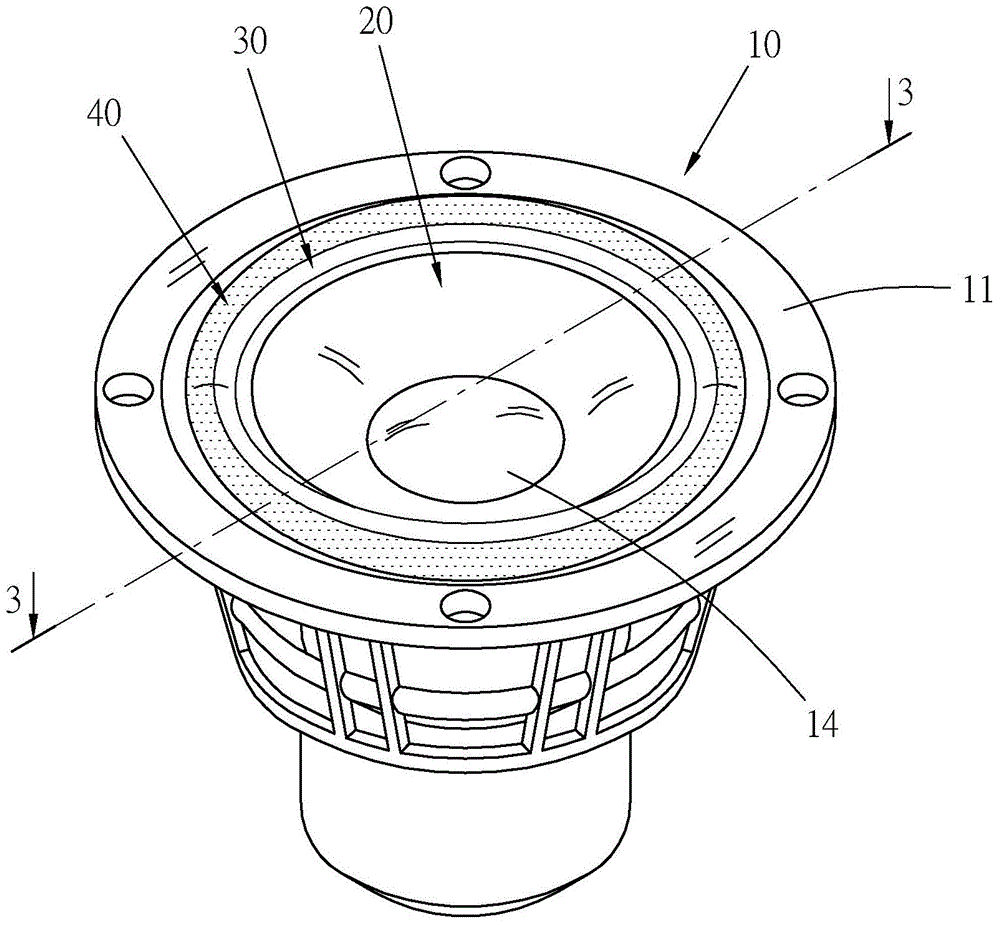

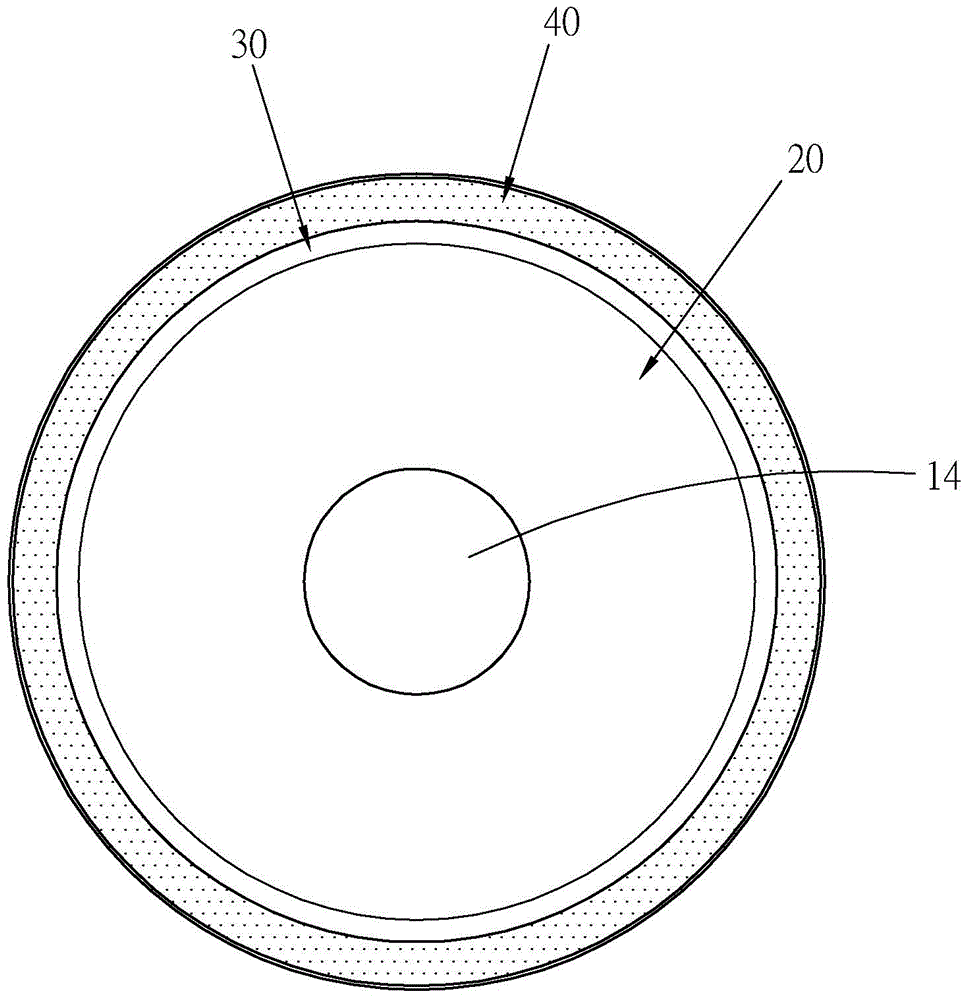

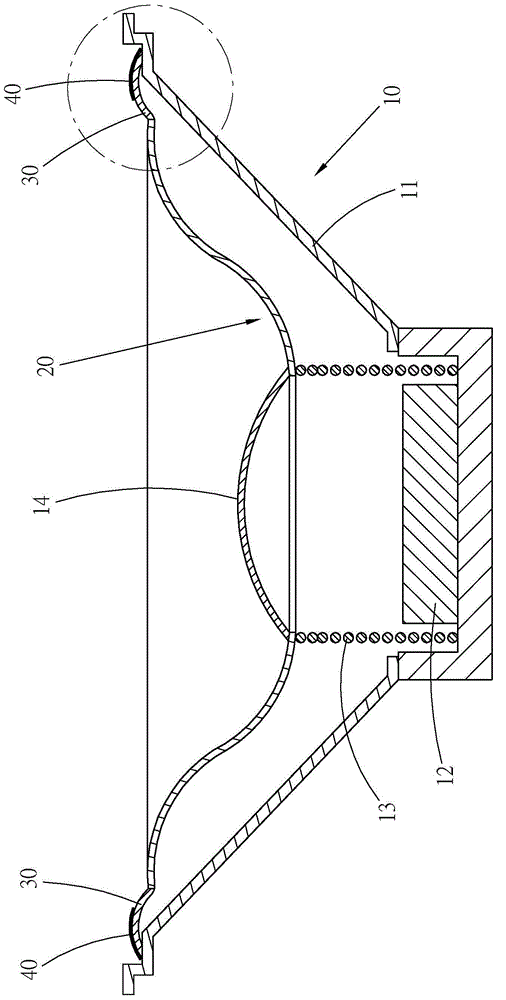

[0038] see Figure 1 to Figure 4 , is the speaker 10 for reducing the diaphragm vibration wave provided by the first preferred embodiment of the present invention, which has a diaphragm 20 installed in the speaker 10, and the diaphragm 20 and the speaker 10 are connected by a hanging edge 30.

[0039] The vibrating membrane 20 is a cone-shaped thin object, which is flexible and can be made of materials such as metal, polymer material, paper or fiber (carbon fiber or glass fiber).

[0040] In detail, the loudspeaker 10 has a frame 11 , a magnetic component, a hanging edge 30 , a diaphragm 20 and a dustproof cover 14 . The magnetic assembly is installed between the frame 11 and the vibrating membrane 20 , and includes a magnet 12 and a coil 13 to generate magnetic forces that attract or repel each other to push the vibrating membrane 20 to move in the axial direction of the coil 13 . The hanging edge 30 is ring-shaped, its outer periphery is connected to the frame 11 , and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com