A switch matrix driving circuit and method

A drive circuit and switch matrix technology, applied in electronic switches, electrical components, pulse technology, etc., can solve the problems of small expandable space of switch matrix, board-level resource occupation, difficulty in adapting to test requirements, etc., to achieve versatility and reliability Scalability, reduction of occupied resources and space, and the effect of meeting miniaturization design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] In the prior art, each driver chip uses separate chip selection, switch level, and address data to realize the operation. However, with the expansion of the scale of the switch matrix, a huge number of control signals will be required to control the switch matrix. Therefore, In order to minimize the utilization of control circuit resources, the present invention provides a switch matrix driving circuit and method, which can realize effective utilization of control circuit resources.

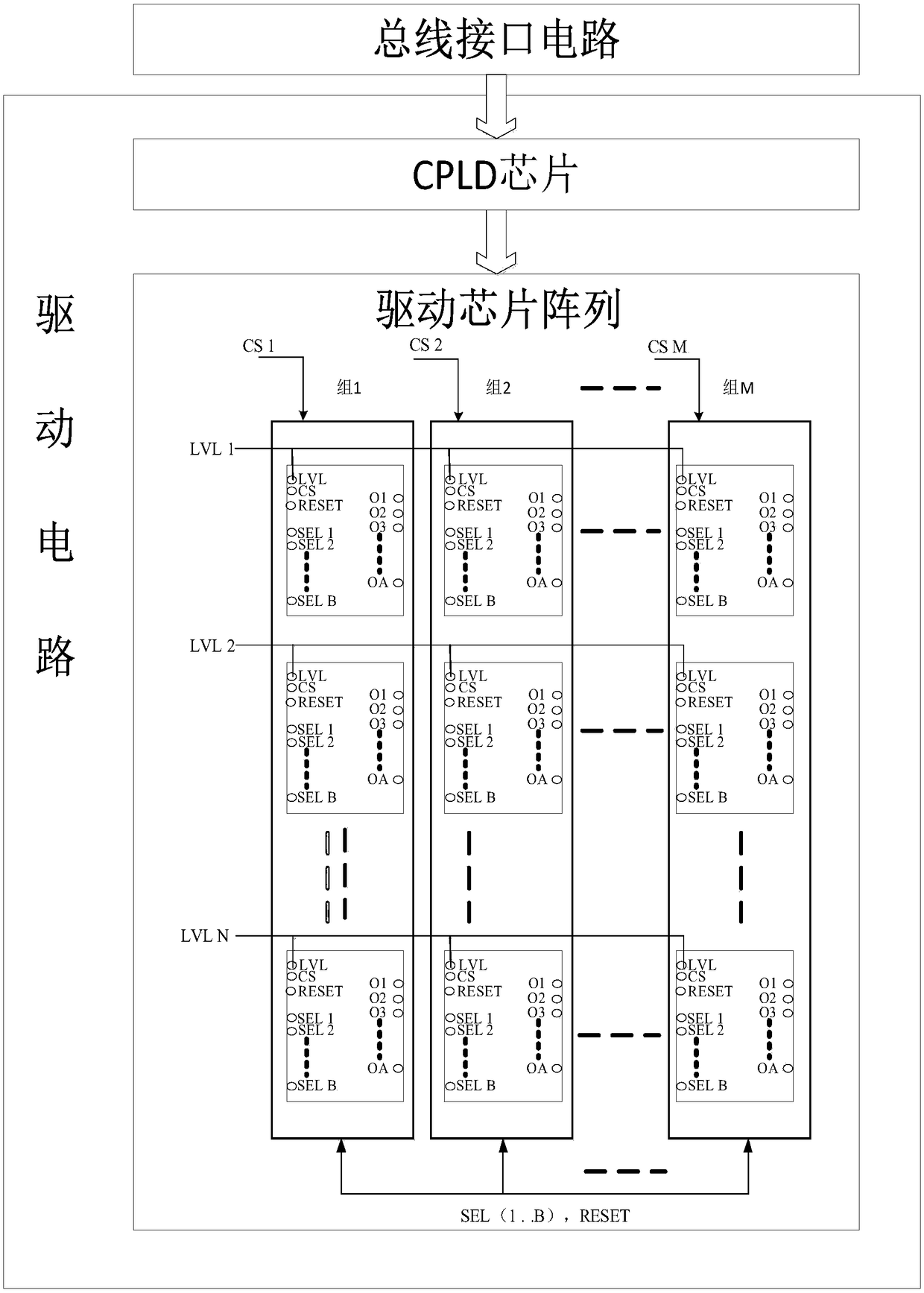

[0031] Such as figure 2 As shown, a switch matrix drive circuit, including:

[0032] The CPLD chip is used to receive the instructions sent by the bus interface and decode the received instructions;

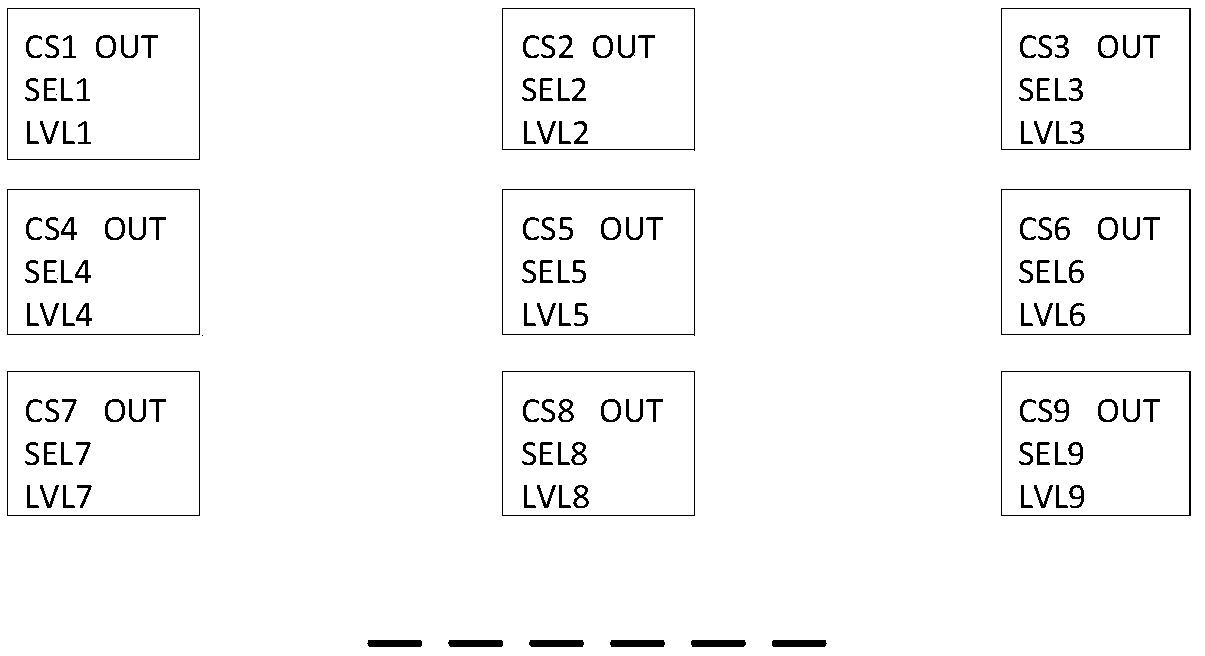

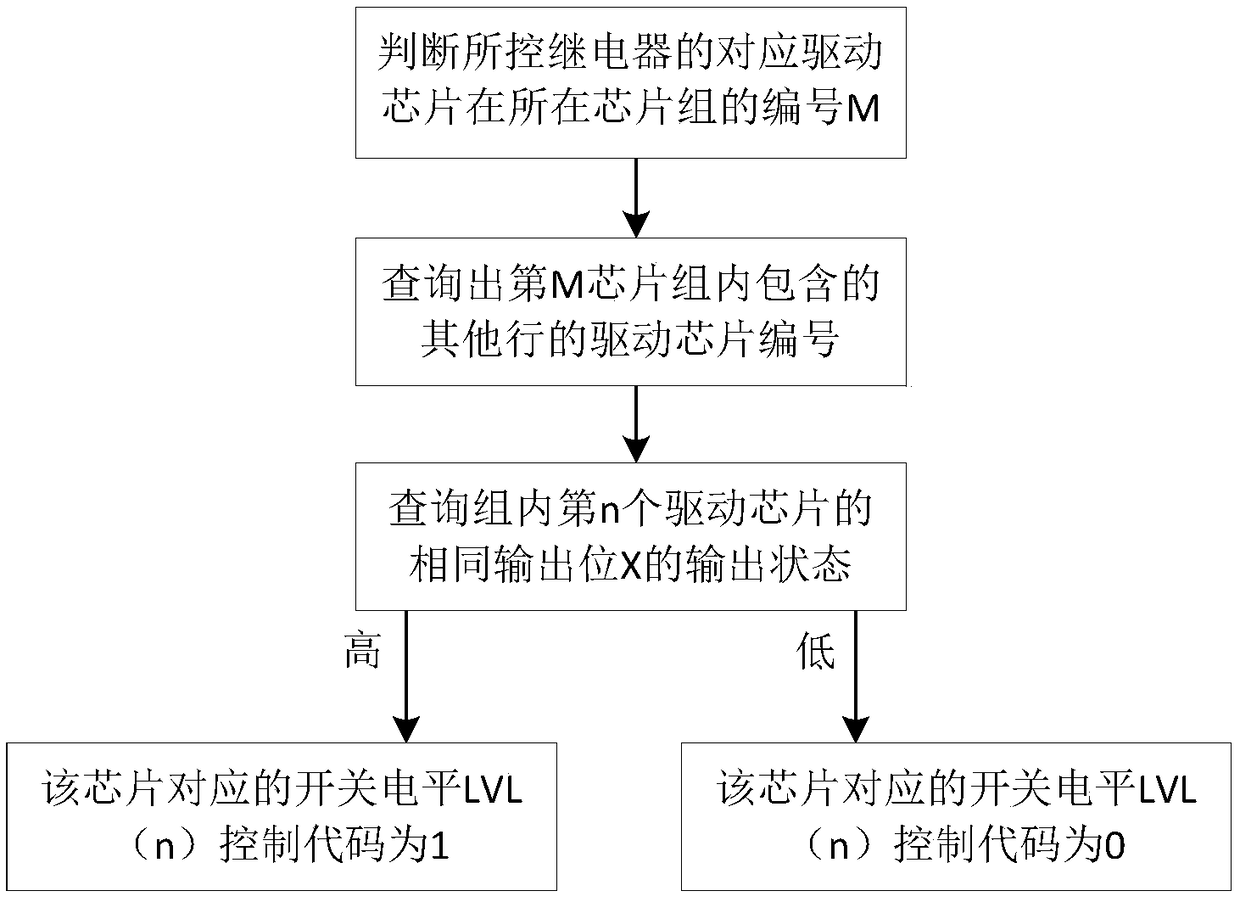

[0033] The relay driver chip is connected with the CPLD chip through the line, and is used to receive the instruction decoded by the CPLD chip, and select the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com