Eight-sided low-power concentrating photovoltaic unit body and its photovoltaic modules and power generation devices

A concentrating photovoltaic, unit cell technology, applied in the field of solar photovoltaic power generation, can solve the problems of unsatisfactory improvement of power generation efficiency of four-sided reflectors, affecting the service life of photovoltaic cells, wasting lighting area, etc., and achieving the problem of overheating and its small impact, The effect of avoiding heat dissipation and cooling conditions and reducing the cost of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

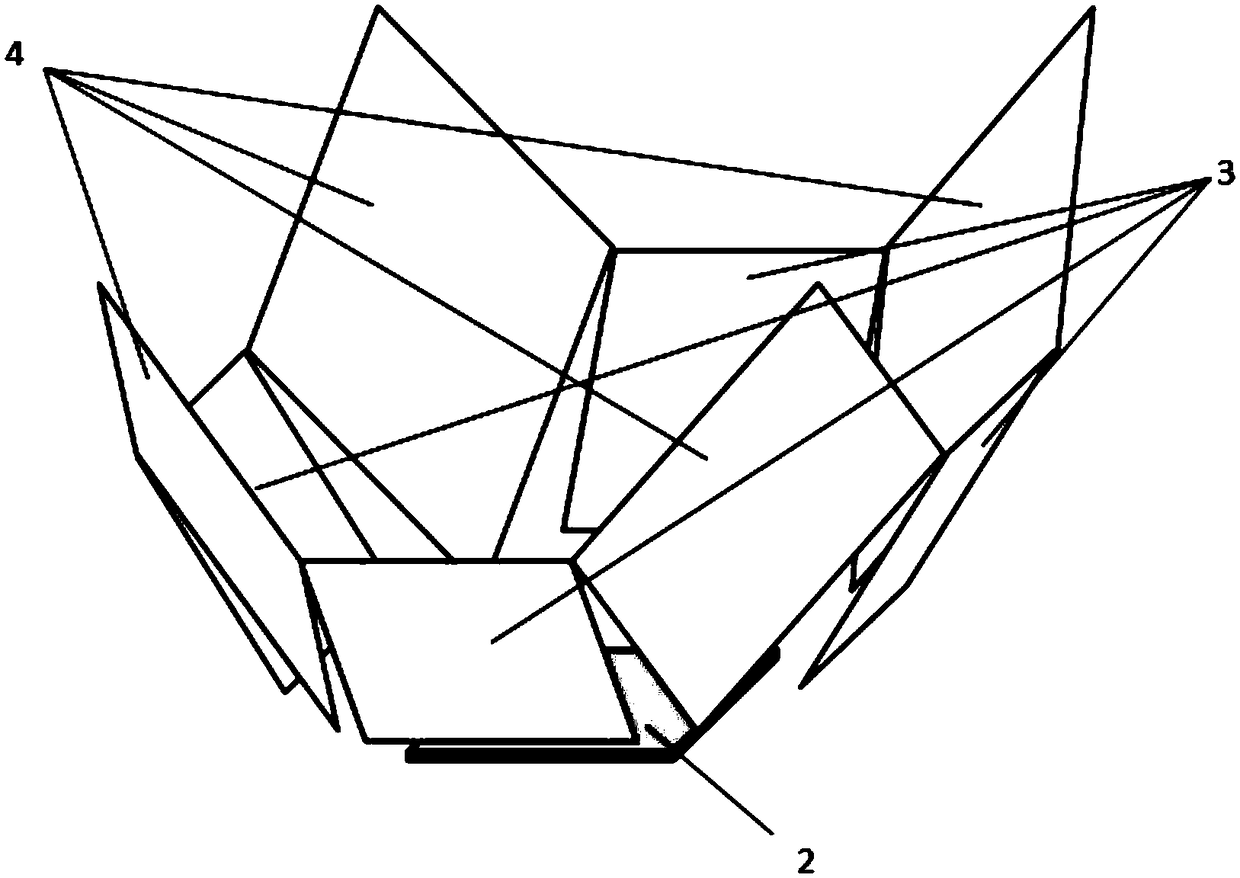

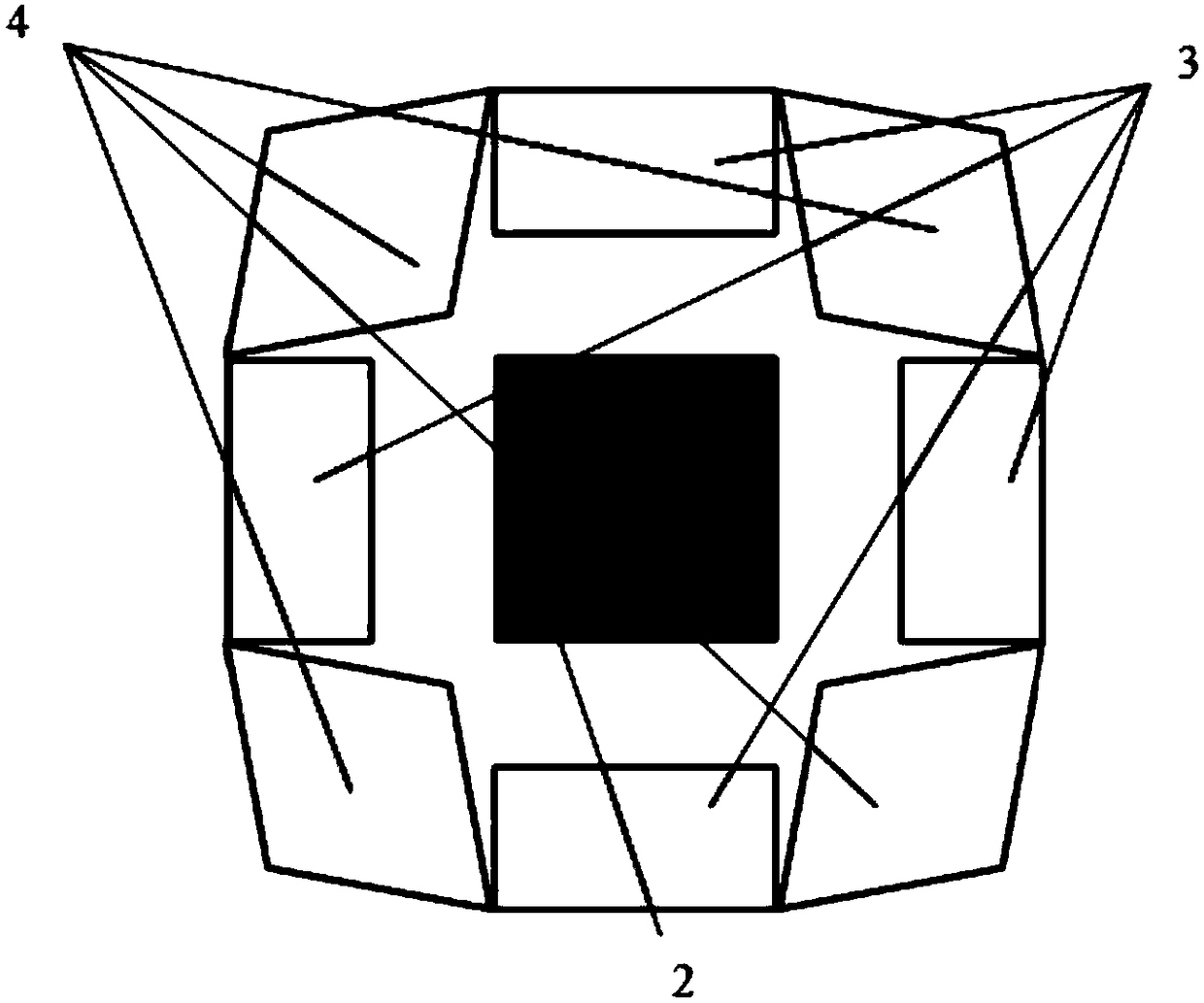

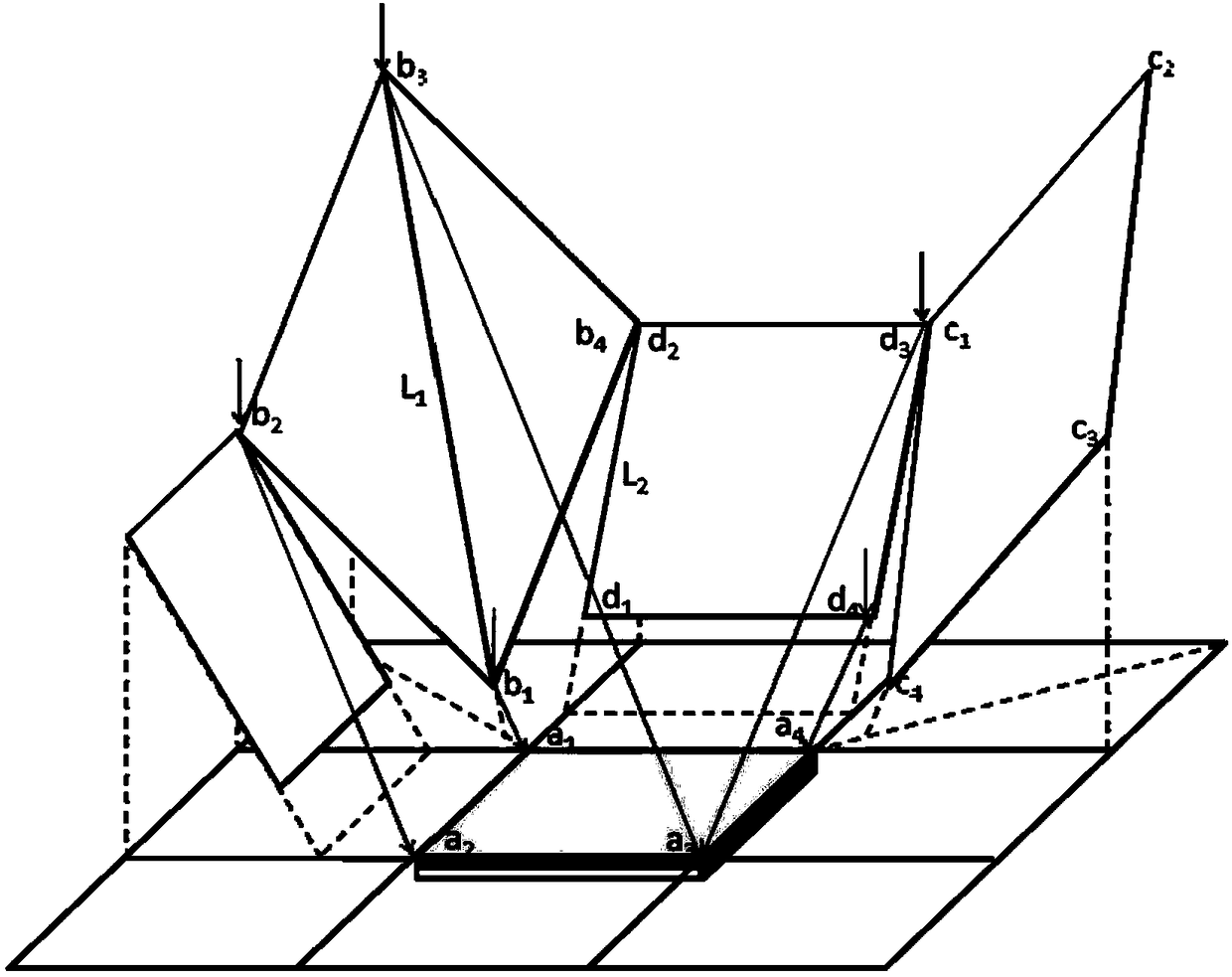

[0042] This embodiment discloses an eight-sided low-magnification concentrating photovoltaic unit body, such as figure 1 and figure 2 As shown, it includes a square photovoltaic cell 2 and four front side reflectors 3 and four oblique side reflectors 4 arranged around the photovoltaic cell. The four front side reflectors 3 are respectively opposite to the four sides of the photovoltaic cell 2, and the four oblique The side reflectors 4 are respectively opposite to the four corners of the photovoltaic cell 2 , so that the front side reflectors 3 and the oblique side reflectors 4 are alternately arranged. The projections of the 8 reflectors on the plane where the photovoltaic cells are located are distributed together with the photovoltaic cells in the Jiugongge centered on the photovoltaic cells, and the projection of the oblique side reflector 4 is located in the square corresponding to the outside of the four corners of the central square of the Jiugongge (hereinafter referr...

Embodiment 2

[0050] This embodiment provides another eight-sided low-power concentrating photovoltaic unit body. The difference from Embodiment 1 is that the photovoltaic cell used in this embodiment is a single crystal cell with a 45° chamfer. See Figure 6 As shown, the minimum square side length L covering the single crystal cell 3 is 156mm, the side length L after removing the chamfer 4 is 125mm, and the length of the right-angled side of the chamfered triangle is 15.5mm.

[0051] In this embodiment, in order to save the process and reduce the manufacturing cost, the ineffective parts corresponding to the chamfers of the front side reflector and the oblique side reflector are not cut off.

Embodiment 3

[0053] This embodiment provides another eight-sided low-power concentrating photovoltaic unit body, such as Figure 7As shown, the difference from Example 1 is that the square photovoltaic cell 2 used in this embodiment is composed of 36 photovoltaic cell sheets arranged in a 6×6 matrix, and the obtained photovoltaic cell 2 is composed of photovoltaic glass, EVA adhesive film Packaged with the backplane, the size of the package is 990mm×990mm, and the size of the radiator 5 installed behind the backplane is 990mm×990mm; the angle α formed by the plane where the diamond-shaped effective reflective surface is located and the plane where the photovoltaic cell 2 is located is set to 115 °, the angle β formed by the plane where the rectangular effective reflective surface is located and the plane where the photovoltaic cell 2 is located is set to 119.66°; correspondingly, it can be obtained through calculation that the size of the rectangular front side reflector 3 is 1021×990mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com