Surface type permanent magnet rotor assembling tool with inclined wedge expansion structure, and assembling method for surface type permanent magnet rotor

A permanent magnet rotor and assembly tooling technology, which is applied in the manufacture of stator/rotor bodies, electromechanical devices, and motor generators, and can solve problems such as inapplicability of permanent magnet rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is a further description of the permanent magnet rotor assembly tool and assembly method of the wedge expansion structure involved in the present invention.

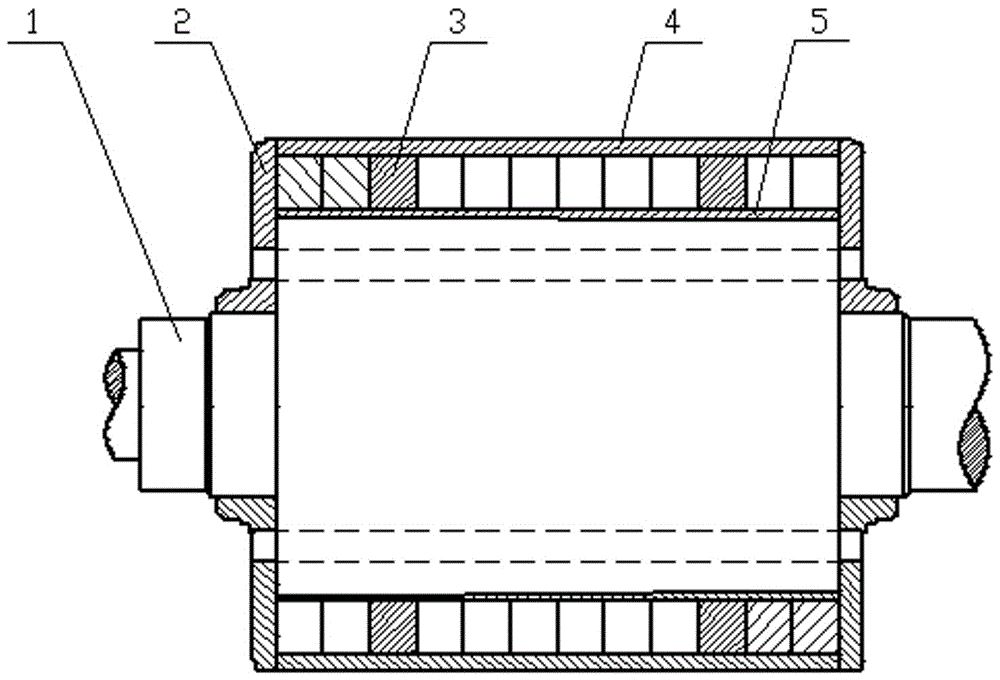

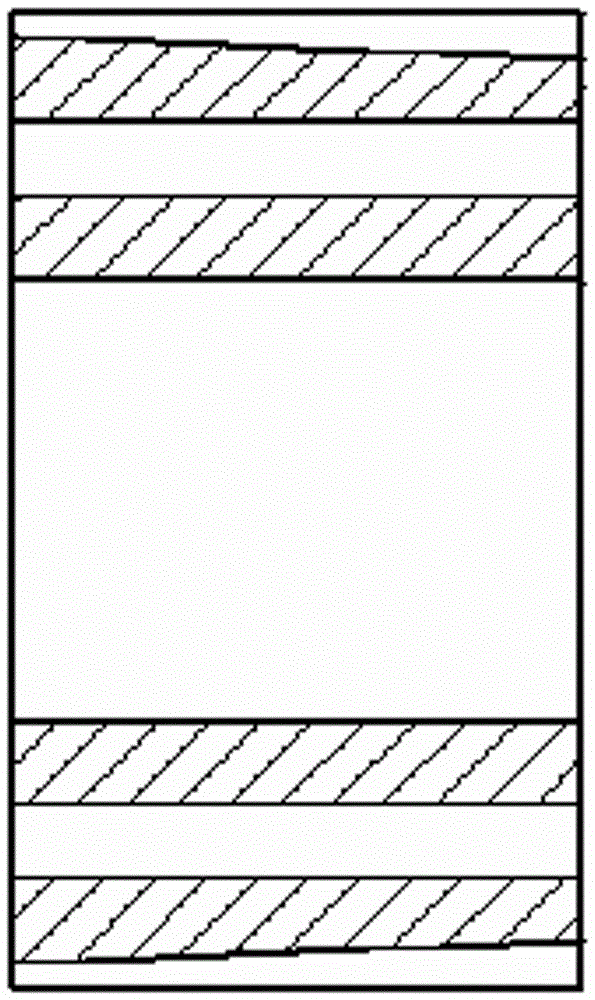

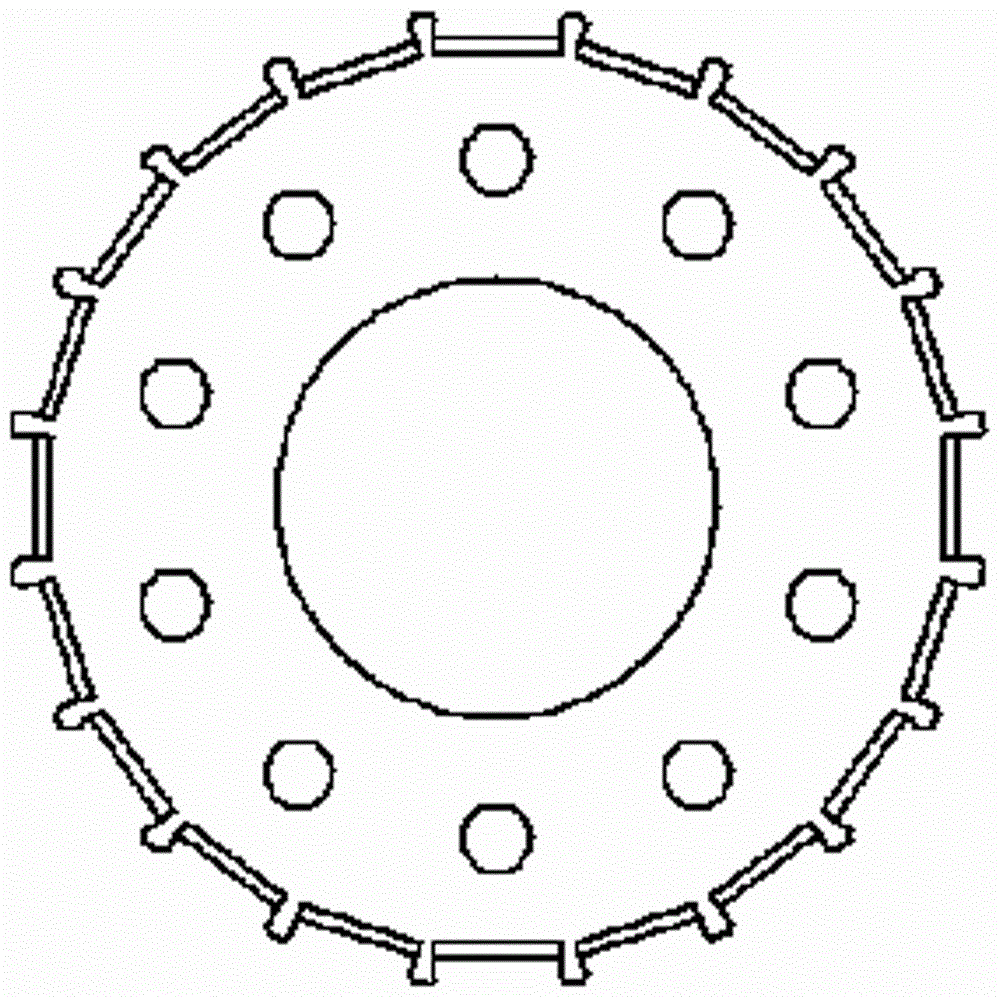

[0034] refer to figure 1 , the surface type permanent magnet rotor assembly tooling of the wedge expansion structure includes a hoop 13, and also includes an axial fixed tooling, a tooling core 2a, and the axial fixed tooling includes an upper pressure plate 11, a middle pressure plate, a lower pressure plate 7, and a bottom plate 6 , pull bar 12, adjusting rod 10, one end of the tooling iron core 2a is in contact with the deep groove end face of the rotor iron core 14 oblique wedge grooves, the tooling iron core 2a is consistent with the shape of the rotor iron core 14, and the length of the tooling iron core 2a is greater than Or equal to the process distance of the axial advancement of the wedge 5, the wedge groove of the tooling iron core 2a is an extended chute of the rotor iron core 14 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com