Nitrate explosive charge safety storage service life estimation method

A storage life, nitrate ester technology, applied in the direction of measuring devices, chemical analysis by titration, material analysis by optical means, etc., can solve the problem of uneven distribution of stabilizer content, uneven distribution of temperature field, combustion and explosion, etc. problems, to achieve the effect of solving the uneven distribution of low-content samples, overcoming the problems of preparation and proportioning, and avoiding the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: Safe storage life of nitrate propellant charge

[0086] The typical three-base propellant SGF-1 is used as a representative for illustration.

[0087] (1) Preparation of near-infrared modeling samples with effective content of No. Ⅱ neutralizer by thermal accelerated aging method

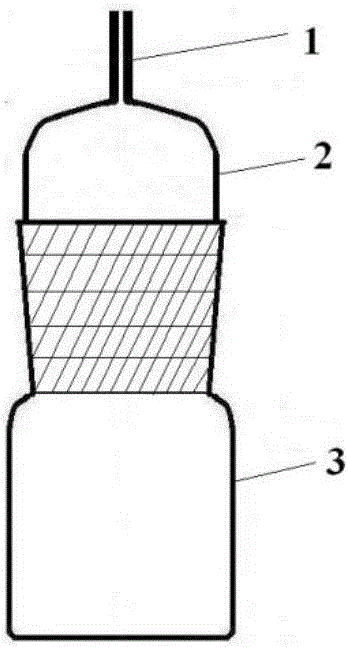

[0088] A typical three-base propellant SGF-1 is packed into a capillary vent grinding-mouth reducing bottle (Φ=4cm, H=8cm) (semi-closed condition, figure 1 ) at 95°C for thermally accelerated aging, sampling every 4 hours, preparing three-base propellant samples with different stabilizer contents, and collecting 60 SGF-1 aging samples, 29 of which (numbered 1-29) were used as internal calibration sets , perform linear fitting and internal cross-validation, and 31 samples are used as an external validation set (numbered 30-60) for external validation.

[0089] (2) Near-infrared quantitative model of the effective content of No. Ⅱ medium-dosed agent

[0090] ① The devices used ...

Embodiment 2

[0117] Embodiment 2: safe storage life of nitrate propellant charge

[0118] The typical composite modified double-base propellant GST-1 is taken as a representative for illustration.

[0119] (1) Preparation of near-infrared modeling samples with effective content of compound stabilizer by thermal accelerated aging method

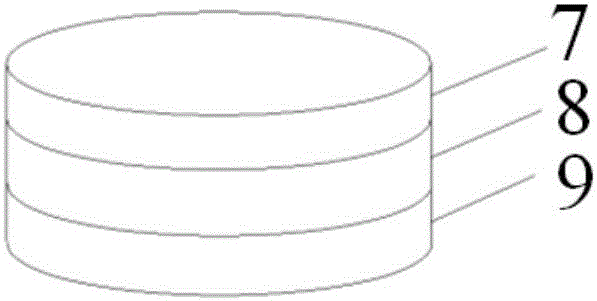

[0120] Typical composite modified double base propellant GST-1 drug cake sandwich structure sample (Φ=30mm, upper tablet 7H1=5mm, sandwich layer 8H2=10mm, lower tablet 9H3=5mm, image 3 ) into a ground-mouth reducing bottle with a capillary vent (semi-closed condition, figure 1 ) at 90°C for thermally accelerated aging, the sandwich layer 8 was taken every 2 hours to obtain composite modified double-base propellant samples with different stabilizer contents, and 60 GST-1 aging samples were collected, of which 29 samples (numbered 1- 29) As an internal calibration set, linear fitting and internal cross-validation are performed, and 31 samples are used as ...

Embodiment 3

[0160] Embodiment 3: safe storage life of nitrate ester explosive charge

[0161] The typical nitrate explosive NEP-1 is used as a representative for illustration.

[0162] (1) Modeling samples for the effective content of No. Ⅱ medium-fixing agent prepared by thermal accelerated aging method

[0163] Typical nitrate ester explosive NEP-1 drug cake sandwich structure sample (Φ=30mm, upper tablet 7H1=5mm, sandwich layer 8H2=10mm, lower tablet 9H3=5mm, image 3 ) into a ground-mouth reducing bottle with a capillary vent (semi-closed condition, figure 1 ) at 85°C for heat-accelerated aging, and the sandwich layer 8 was taken every 2.5 hours to obtain a total of 60 calibration set samples and external validation set samples with different effective contents of No. ) is used to model the internal calibration set samples, which participate in linear fitting and internal cross-validation, and 31 samples (numbered 30-60) are used as external validation sets for external validation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com