A simple automatic sampling device and control method for a belt conveyor

A technology of automatic sampling device and belt conveyor, which is applied in the direction of sampling device, etc., to achieve the effect of simple device structure, good sampling interception effect and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

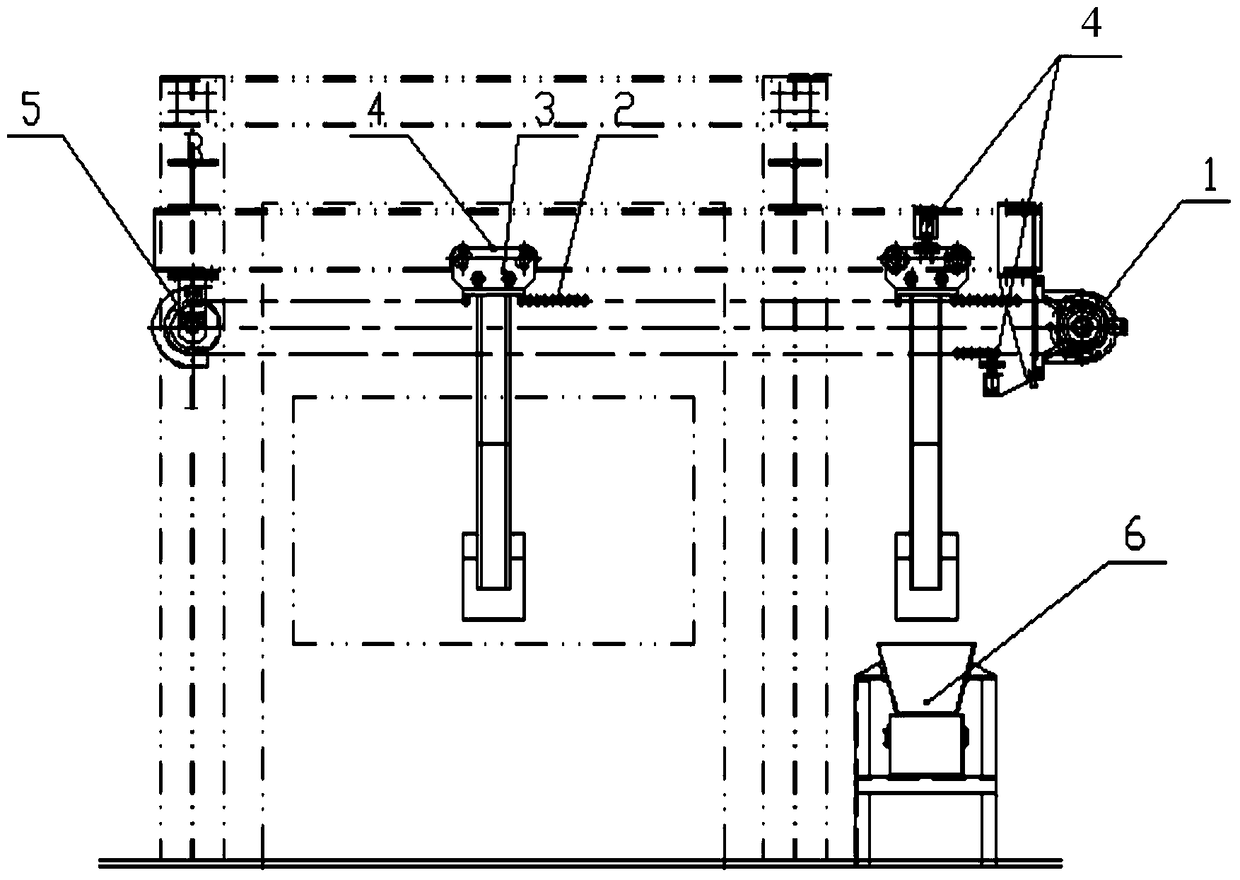

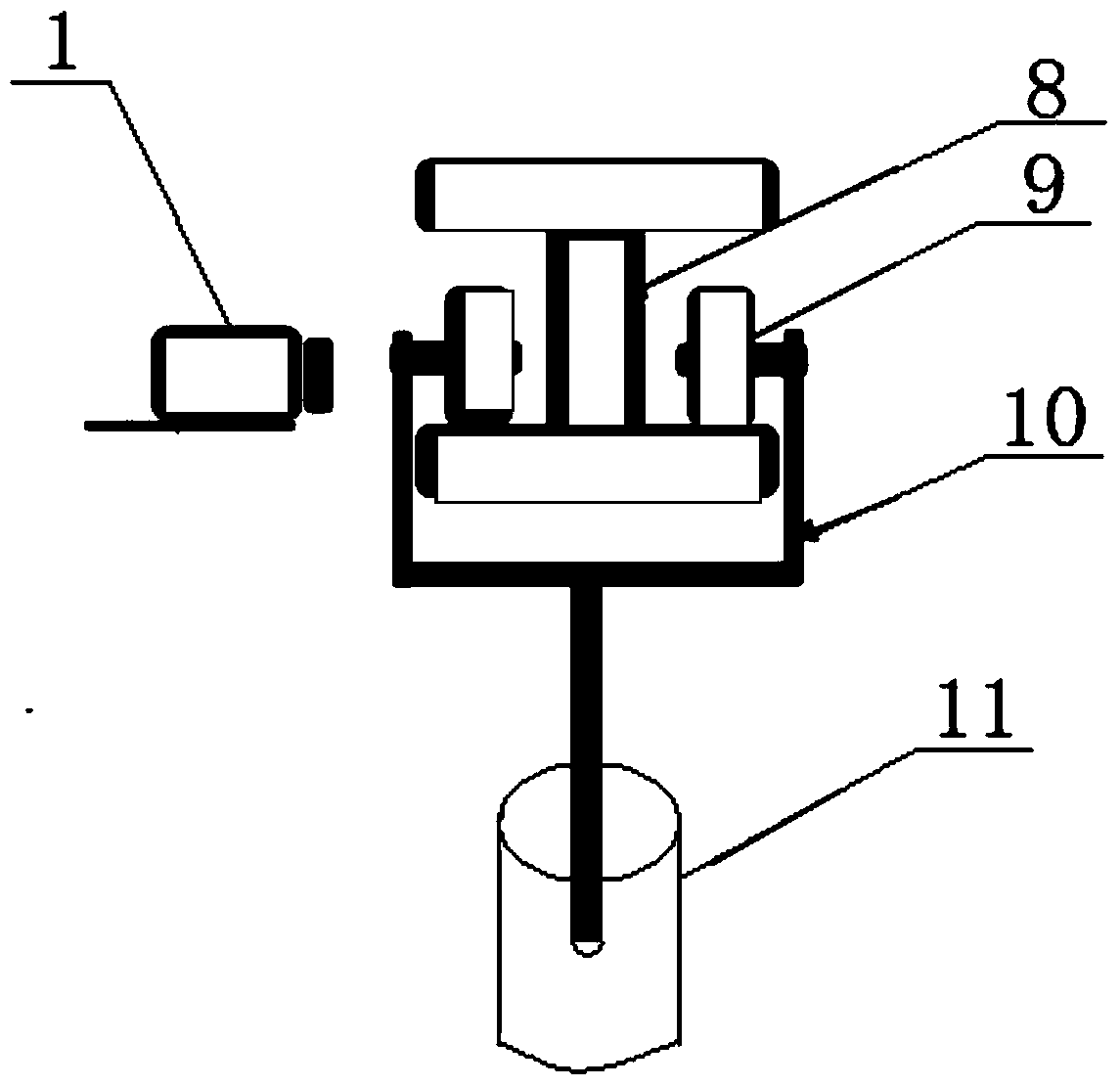

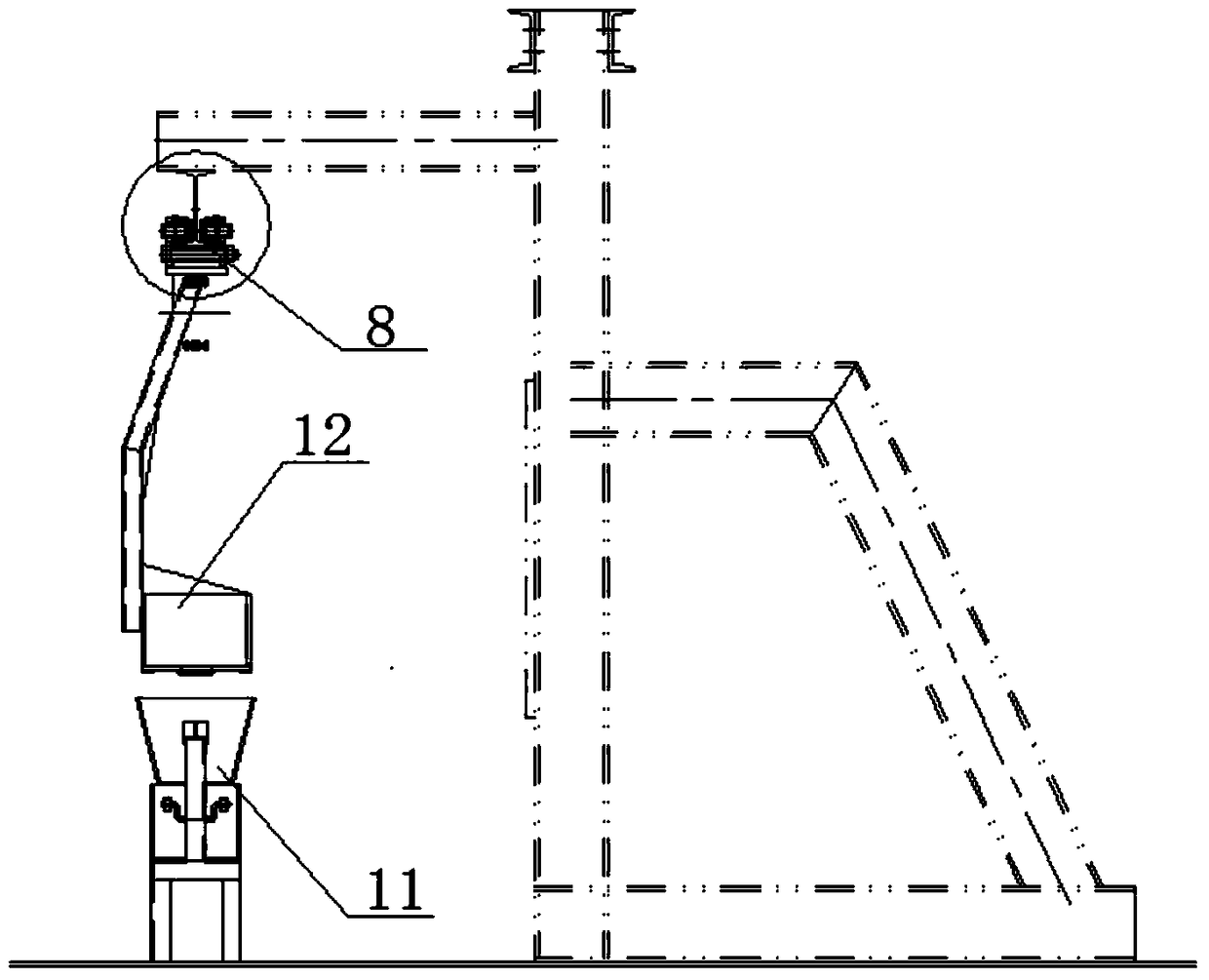

[0039] The invention provides a structure of a simple automatic sampling device for a belt conveyor such as Figure 1~6 As shown, it includes a sliding track 8 arranged at the top of the belt conveyor chute, a hanger 3 is arranged on the sliding track 8, and the hanger 3 includes a sliding wheel 9 suspended on the sliding track 8 and a sampling bucket 12 for sampling operations It also includes a driving motor 1, which drives the hanger 3 to move on the sliding track 8 through the induction wheel 5 and the transmission chain 2; it also includes a sample tank center 6 and two sets of travel switches 4, wherein the sample tank center 6 is located at Below the drive motor 1, one set of travel switches 4 is set on the hanger 3, and the other set is set on the side of the drive motor 1; it also includes a position contact switch 10 set at the material end of the belt conveyor, and the sampling bucket 12 slides along with it. The wheel 9 enters the sampling area of the belt convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com