Shelf beam column node low-temperature fatigue life system and method for detecting cold storage

A technology of beam-column joints and fatigue life, applied in the direction of measuring devices, elastic testing, machine/structural component testing, etc., can solve problems such as economic loss, fatigue damage, and no warning of structural components, so as to avoid property loss, The effect of avoiding damage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

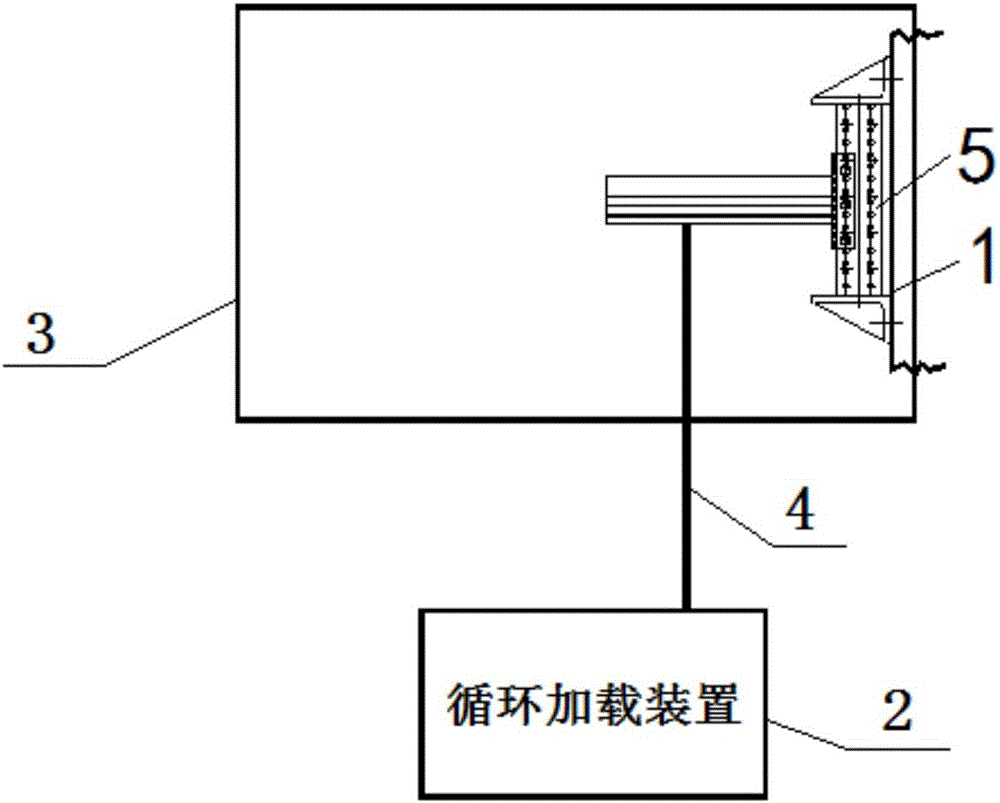

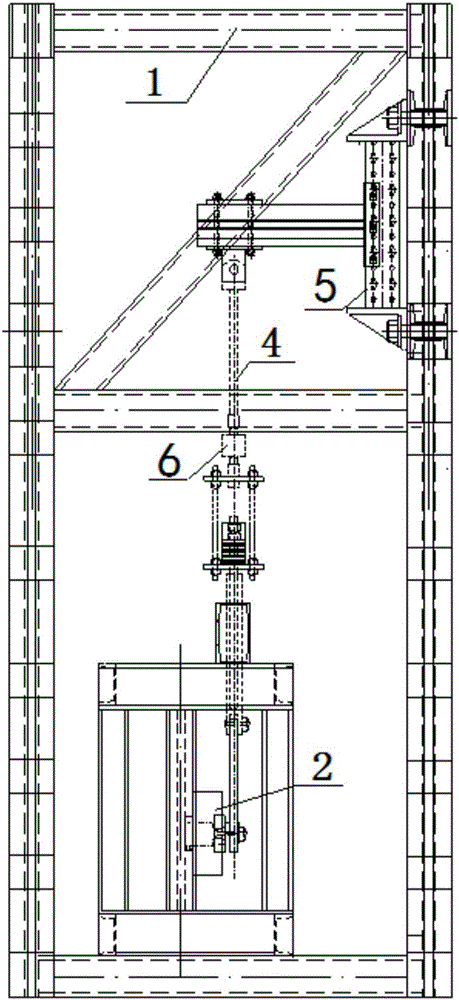

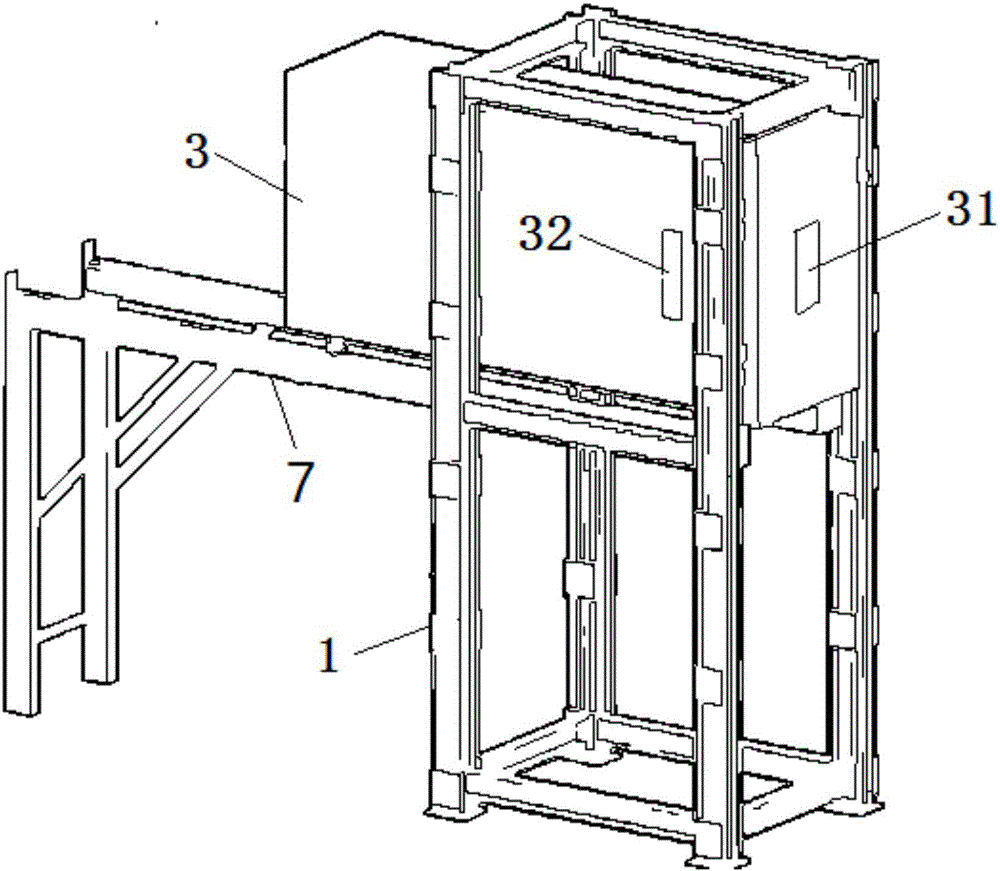

[0033] Such as Figure 1-3 As shown, a system for detecting low-temperature fatigue life of beam-column joints of shelves for cold storage, including a fixing device 1, a cyclic loading device 2, a cooling device 3 and a connecting device 4,

[0034] The fixing device 1 is used to fix the beam-column joint specimen 5 of the shelf for the cold storage to be tested;

[0035] The cyclic loading device 2 is used for applying low-frequency cyclic test load;

[0036] The cooling device 3 is used to provide a low-temperature environment for the shelf beam-column joint specimen 5 to be tested for cold storage;

[0037] The connecting device 4 is used to transmit the application and unloading of the test load of the cyclic loading device 2 .

[0038] The system for detecting the low-temperature fatigue life of the beam-column joints of shelves used in cold storage also includes a tension-compression sensor 6, a force gauge and a counter. And the dynamometer is used to measure the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com