Non-fouling plate and shell heat exchanger

A heat exchanger, plate and shell technology, applied in the field of heat exchangers, can solve the problems of restricting the development of new technologies, destroying water circulation, increasing the maintenance of heat exchange equipment, etc. Adverse effects, advanced effects of anti-scaling and descaling principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

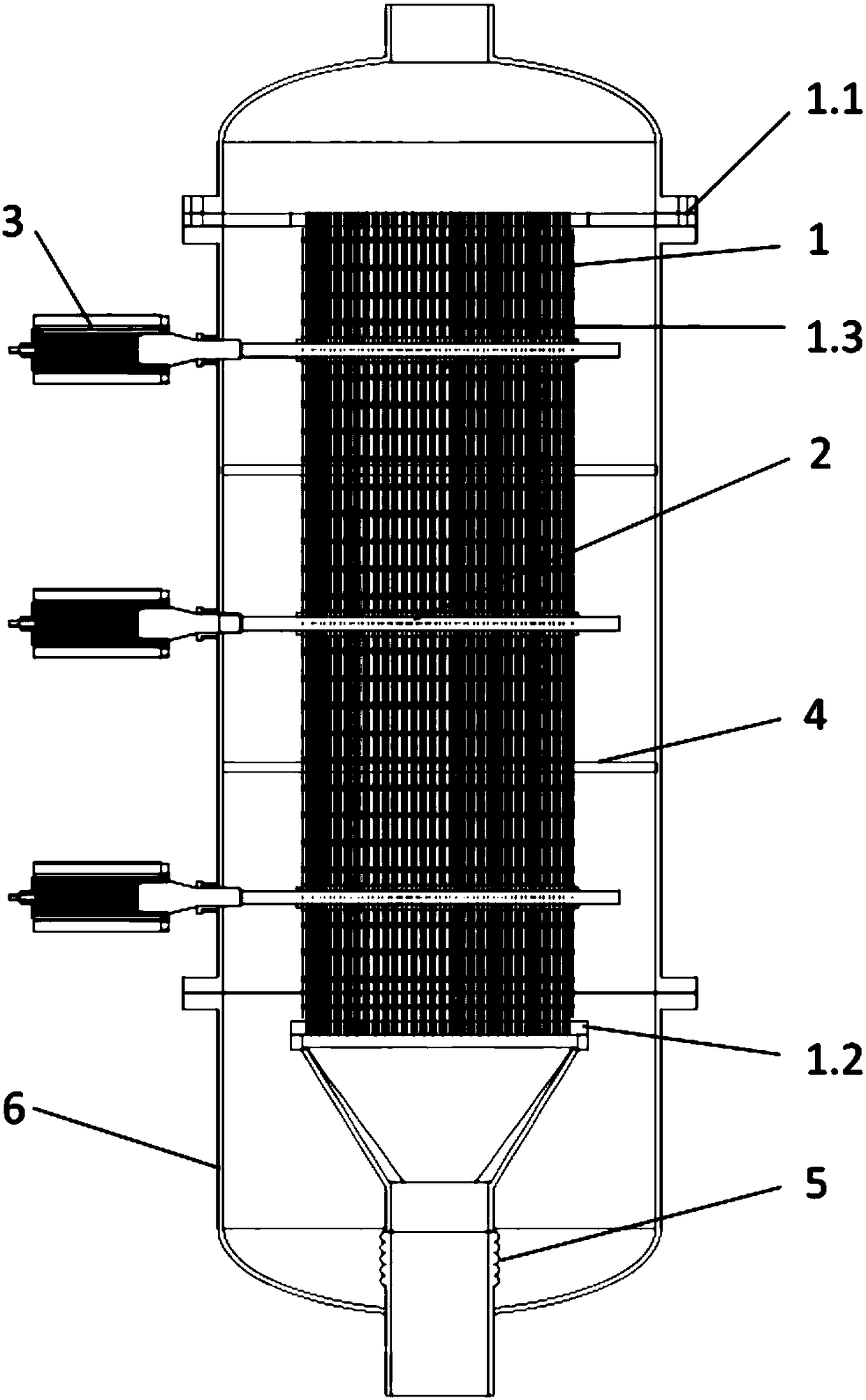

[0079] see figure 1 , the present invention discloses a non-fouling plate and shell heat exchanger. The non-fouling plate and shell heat exchanger includes: heat exchange plate group 1, at least one longitudinal power ultrasonic transmission system 2, at least one power energy wave Generator 3, at least one diversion plate 4, expansion joint 5, housing 6;

[0080] The heat exchange plate group 1, each longitudinal power ultrasonic transmission system 2, and each flow guide partition 4 are arranged in the housing, and the power energy wave generator 3 is connected to the corresponding longitudinal power ultrasonic transmission system 2; the inside of the heat exchanger and the tube plate The expansion joint 5 is arranged between them.

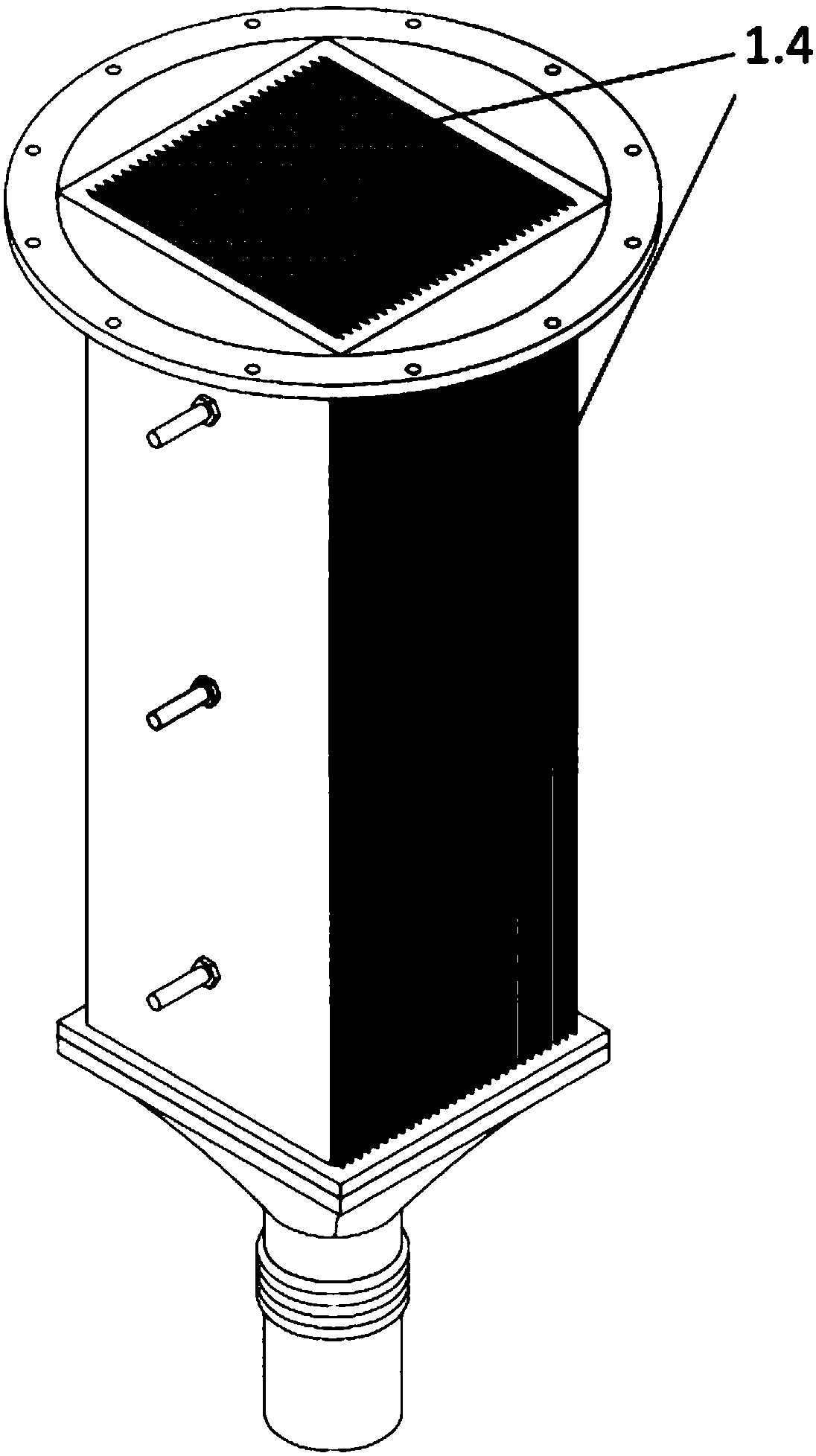

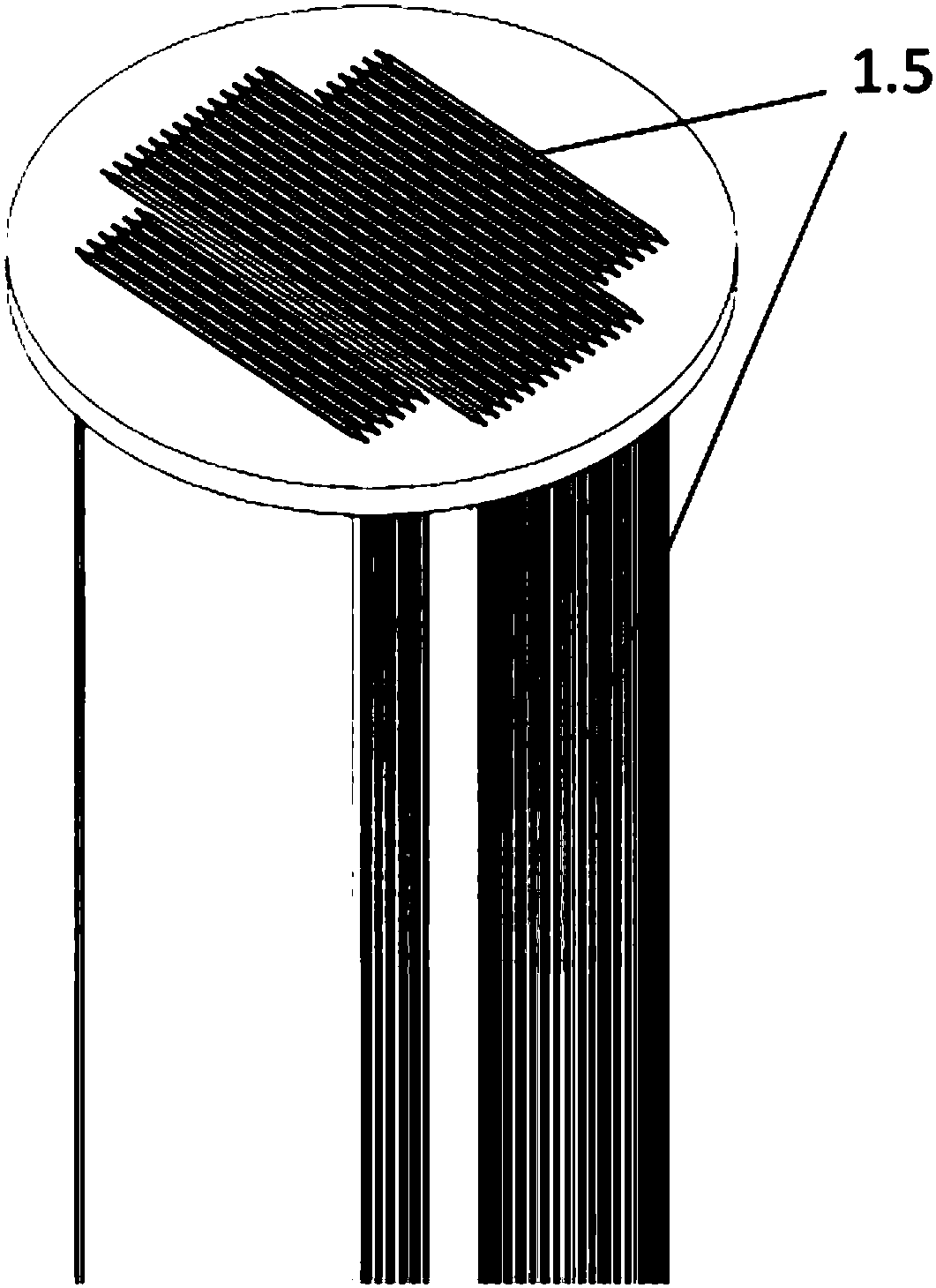

[0081] The heat exchange plate group 1 includes: an upper tube plate 1.1, a lower tube plate 1.2, and a heat transfer fin 1.3; the heat transfer fin 1.3, the upper tube plate 1.1, and the lower tube plate 1.2 must be well welded.

[0082] Such...

Embodiment 2

[0097] A non-fouling plate and shell heat exchanger, the non-fouling plate and shell heat exchanger includes: heat exchange plate group, at least one longitudinal power ultrasonic transmission system, at least one power energy wave generator, at least one guide Partition, shell;

[0098] The heat exchange plate group, each longitudinal power ultrasonic transmission system, and each deflector partition are arranged in the shell, and the power energy wave generator is connected to the corresponding longitudinal power ultrasonic transmission system; expansion joint.

[0099] In summary, the non-fouling plate and shell heat exchanger proposed by the present invention not only has the characteristics of high heat exchange efficiency and small footprint of the plate heat exchanger; it also has the high temperature and high pressure resistance of the shell and tube heat exchanger. Features, and the enhanced heat transfer effect is remarkable, representing the development direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com