A side fan type cabin wood drying device and drying method

A wood drying and cabin technology, which is applied in the direction of drying gas arrangement, drying room/container, drying solid materials, etc., can solve the problems of heavy quarantine and pest control of imported wood, prolonging the production and processing cycle of wood, and the inability to dry wood, etc. Achieving good drying quality, reducing the process of detoxification and making up for the effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

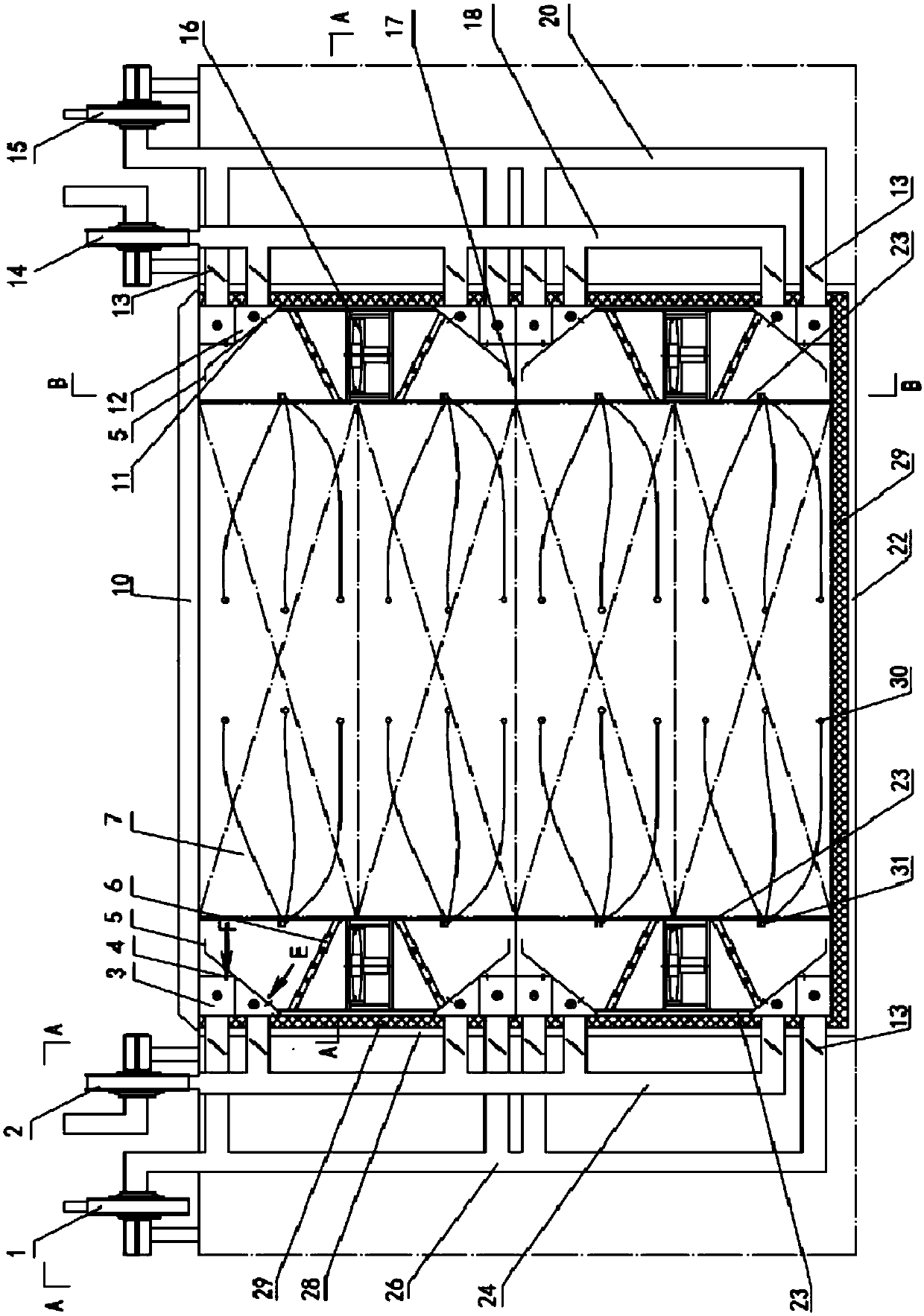

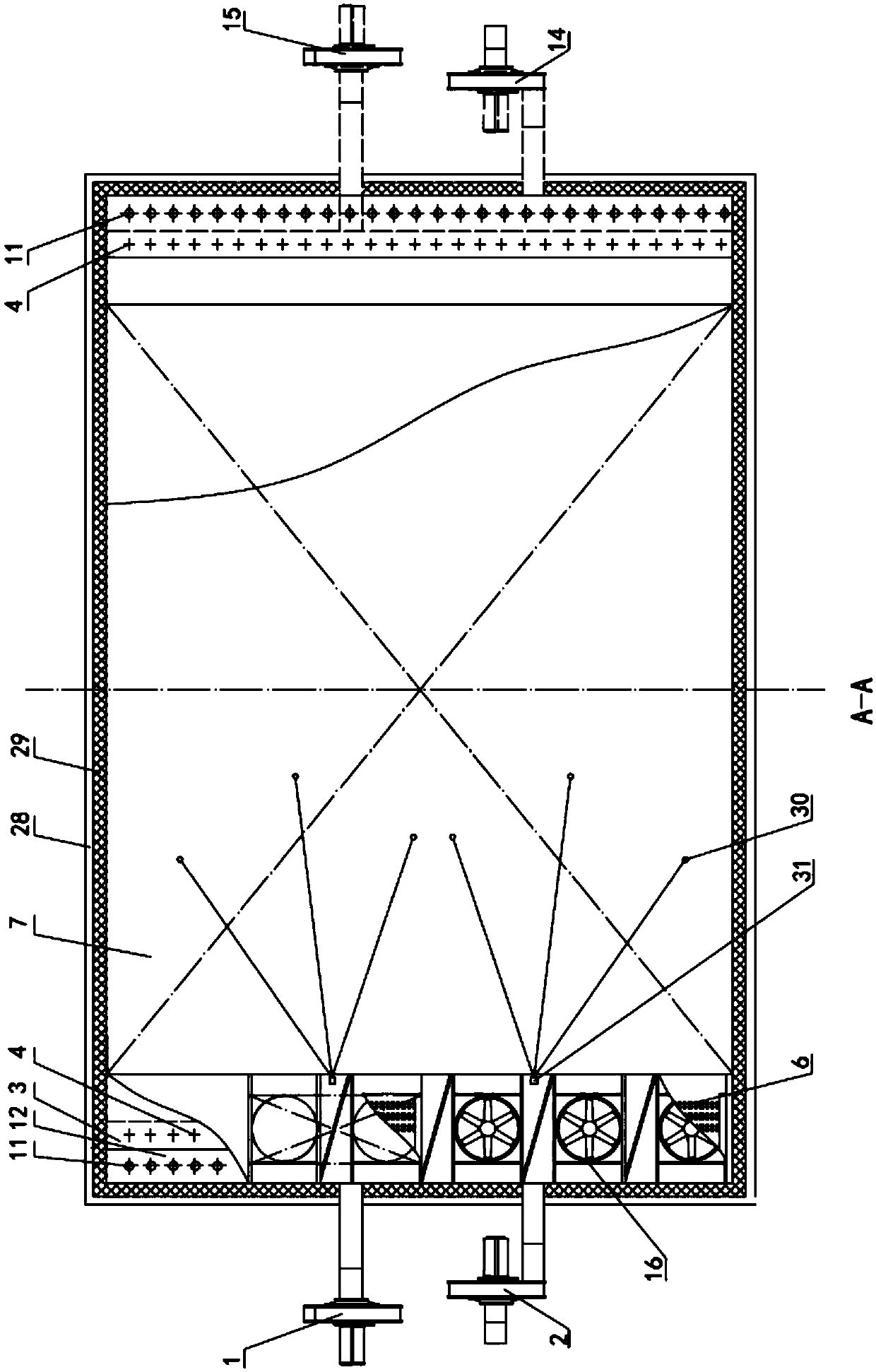

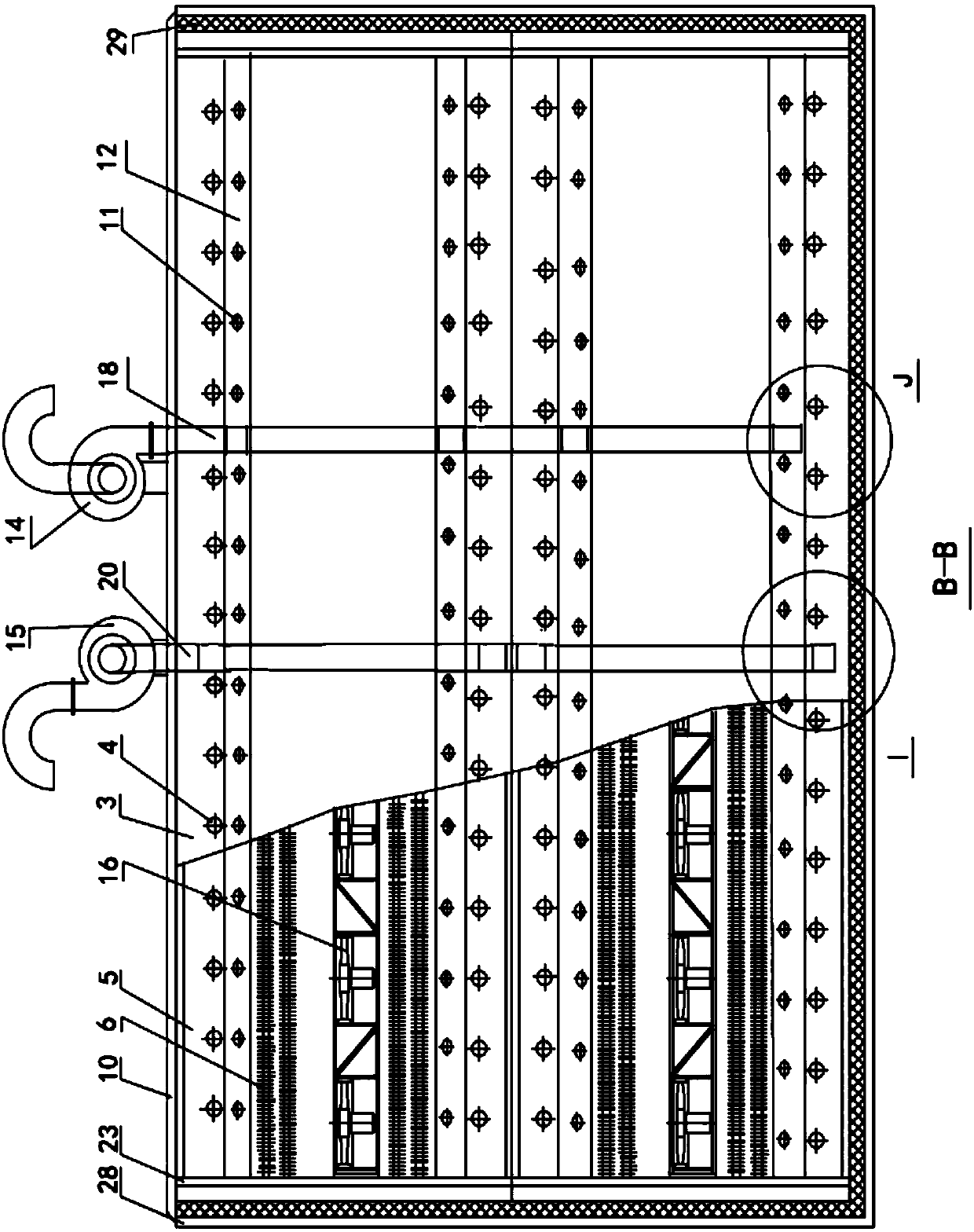

[0046] Specific implementation mode one: as Figure 1 to Figure 10 As shown, a side fan type cabin wood drying device of the present embodiment includes a cabin loaded with dried wood; a cabin equipment carrying frame installed on both sides of the cabin; a drying device installed inside and outside the cabin for humidity control and ventilation. system; the wood drying medium forced circulation system installed on the carrying frame of the equipment in the cabin; the heat exchanger system or heater system installed on the carrying frame of the equipment in the cabin; the sensor for detecting the state of the drying medium installed on the carrying frame of the equipment in the cabin System; sensor system for detecting moisture content of dried wood placed in wood piles.

specific Embodiment approach 2

[0047] Specific implementation mode two: as figure 1 As shown, the equipment carrying frame 23 in the cabin of the present embodiment is respectively connected with the bulkhead and the bottom of the cabin and fixed on both sides of the cabin, the drying medium forced circulation system 16 of the drying device, the heat exchanger system or the heater system 6, the cabin The air inlet 3, the exhaust duct 11 in the cabin, the drying medium circulation isolation deflector 17, and the drying medium state detection sensor assembly 31 are all installed on the equipment carrying frame 23 in the cabin, and placed in the frame protection to prevent the wood pile 7 from moving The equipment in the cabin is damaged by collision, and the wood pile 7 is hijacked during transportation to prevent scattered piles. Other compositions are the same as the specific embodiment and the specific embodiment one.

specific Embodiment approach 3

[0048] Specific implementation mode three: as Figure 1 to Figure 3 As shown, the humidity control and ventilation system of the drying device of the present embodiment includes two sets of ventilation fans, two sets of intake and exhaust pipelines, and intake and exhaust passages with intake and exhaust openings in the cabin; Install a group of ventilation fans, each group of ventilation fans has an exhaust fan and an intake fan; The channel is connected to realize the adjustment of the humidity of the drying medium in the cabin.

[0049] Such as Figure 1 to Figure 9 As shown, two sets of ventilation fans, two sets of intake and exhaust pipelines, and intake and exhaust passages with intake and exhaust holes in the cabin wood drying device humidity control and ventilation system, of which 1 in the left set The left side air intake ventilator 2 is connected with the air intake duct 12 in the left side cabin through the left side air intake pipeline 24, and one left side exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com