Sludge roller external heat drying and circulating fluidized bed incineration integration and tail gas cleanup device

A tail gas purification device and circulating fluidized bed technology, applied in dehydration/drying/concentrated sludge treatment, incinerator, combustion method, etc. 40% and other problems, to achieve the effect of simple structure, lower operating costs, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

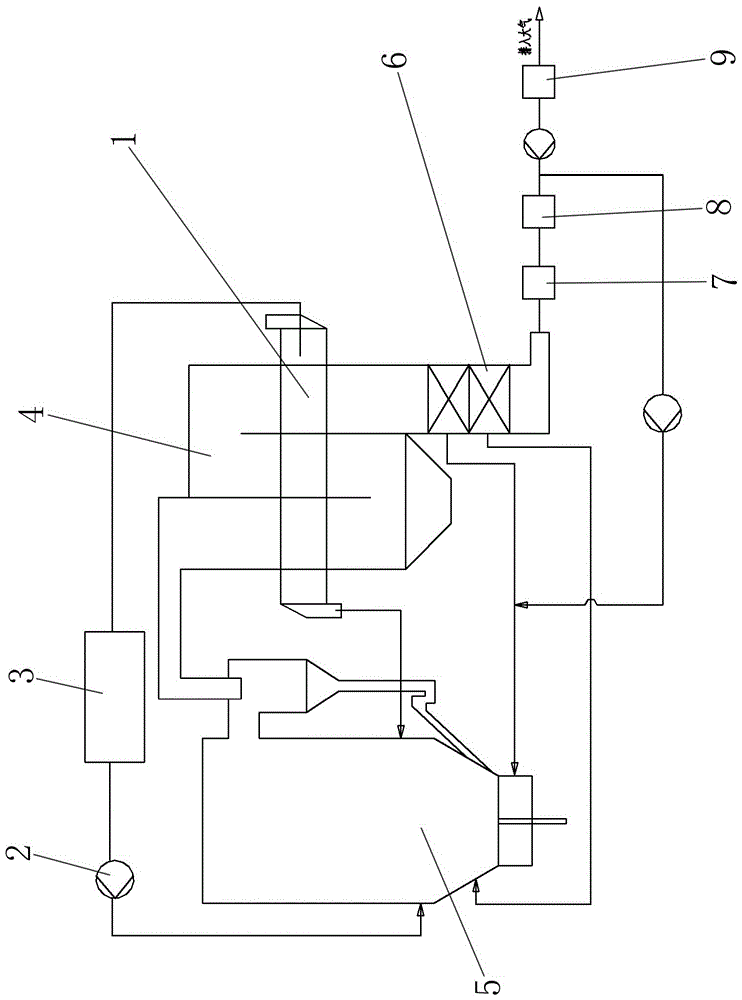

[0008] refer to figure 1 , a sludge drum external heat drying and circulating fluidized bed incineration integration and tail gas purification device, which includes a circulating fluidized bed, a drying system and a tail gas purification system, the drying system includes a rotary kiln drum 1, a fan 2 and The condenser 3 and the rotary kiln drum 1 are interspersed on the tail flue 4 of the circulating fluidized bed. The rotary kiln drum 1 is connected to the tail flue 4 in rotation. The high-temperature flue gas directly heats the outer wall of the rotary kiln drum 1, and indirectly dries the wet sludge in the rotary kiln drum 1. The tail flue 4 adopts an S-shaped rotary circulation structure to increase the drying area of the rotary kiln drum 1. The two ends of rotary kiln drum 1 are respectively provided with feed inlet and discharge outlet. One end of the discharge outlet of rotary kiln drum 1 is inclined downward by three to five degrees, making it easier to unload the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com