Faucet connector

A faucet and water tank technology, applied in the direction of pipes/pipe joints/pipe fittings, valve details, engine components, etc., can solve the problems of large impact force, loud water outlet sound, and high water flow velocity from the faucet, so as to keep quiet, The effect of water pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, this design is illustrated.

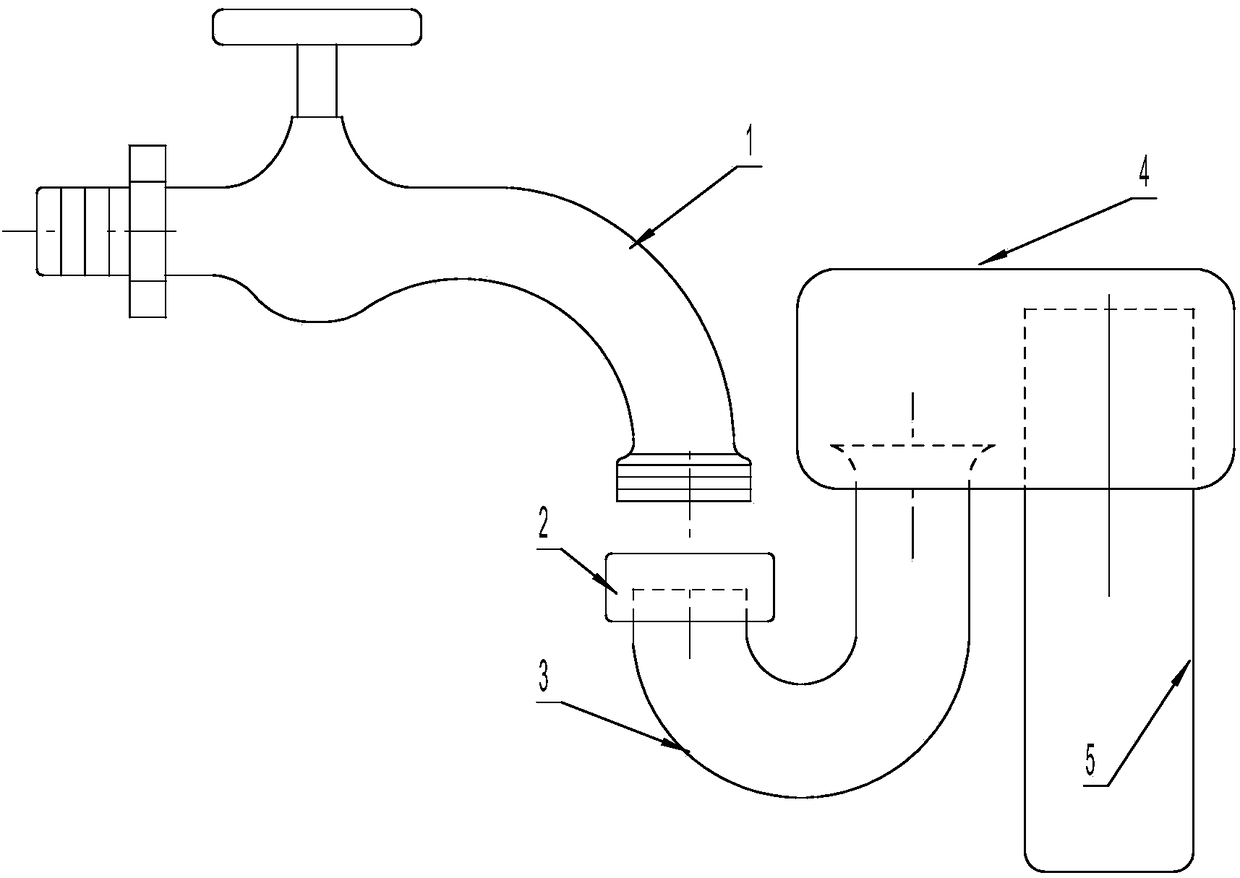

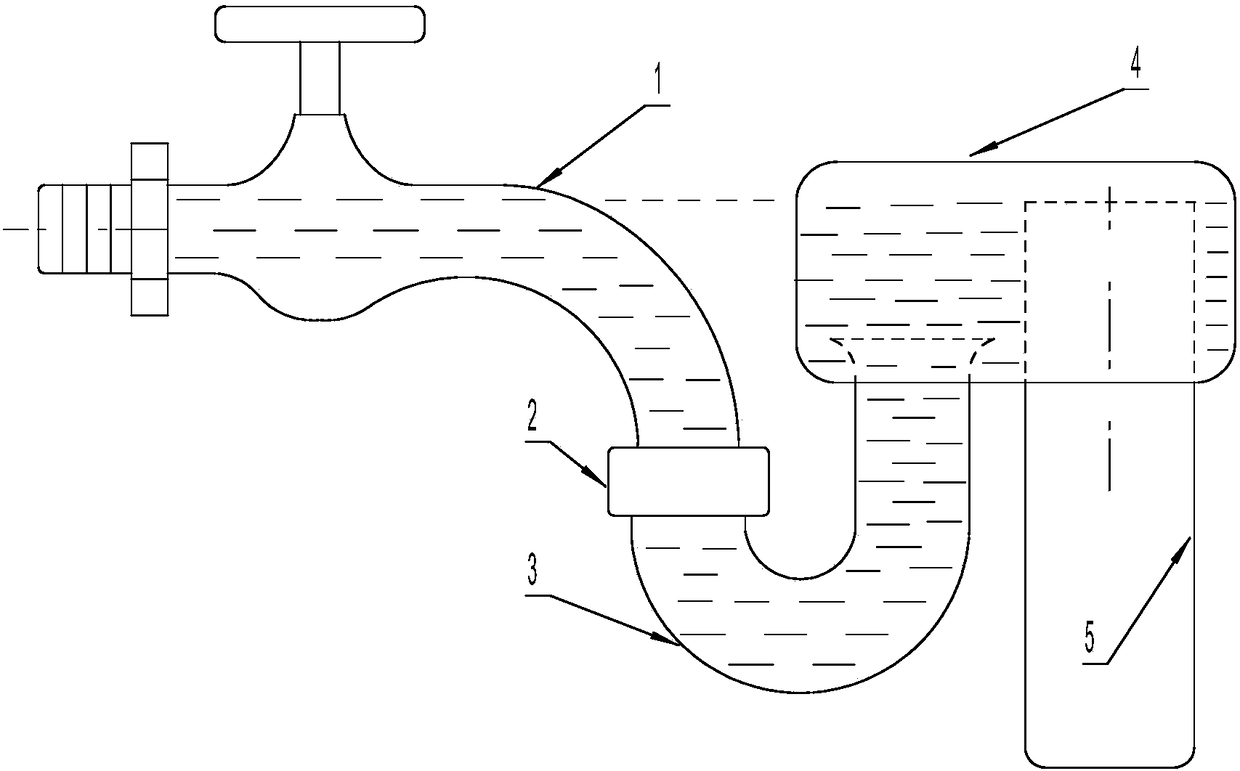

[0010] Such as figure 1 , figure 2 As shown, the faucet joint of this design includes a joint 2, which is a kind of flexible joint, which can be conveniently threaded with the outlet pipe of the faucet 1 to fix the whole device. The pipe 3 is bent downwards, outwards, and upwards to form a 180-degree angle. The outer nozzle of the elbow extends upward for a certain distance beyond the height of the joint and then extends into a hollow rectangular water tank 4 for fixed and airtight connection. The outer nozzle of the pipe 3 is close to the lower bottom of the water tank and should not be too high. At the same time, the water discharge pipe 5, which is straight and has a diameter thicker than the diameter of the outlet pipe of the faucet, is directly sealed from the water tank 4 and installed on the lower bottom of the water tank. , the upper end of the water discharge pipe 5 is close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com