Self-sucking boosting pressure tank

A technology of boosting pressure and self-priming, applied in the field of pressure tanks, can solve the problems of high failure rate, high manufacturing cost, complex structure, etc., and achieve the effect of improving lubrication, avoiding uneven force and improving sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

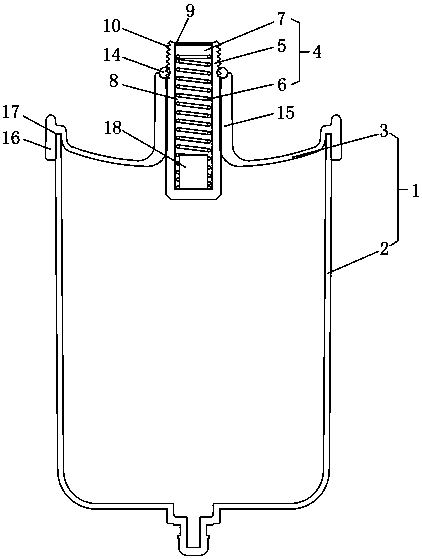

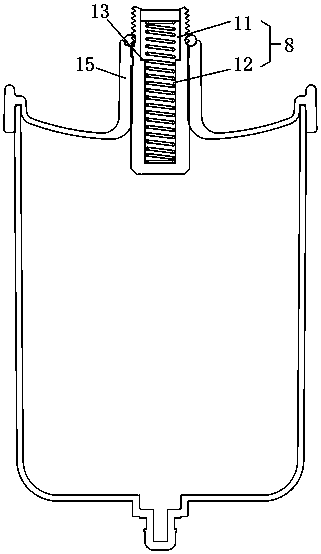

[0020] see figure 1 , the present invention provides a self-priming pressurized pressure tank, including a tank body 1, the tank body 1 includes a shell 2 and a cover 3, the shell 2 and the cover 3 are made of plastic, the cover The center of 3 is provided with hydraulic buffer device 4, and described hydraulic buffer device 4 comprises main body 5, spring 6 and buffer block 7, and the material of described main body 5 and spring 6 is stainless steel, and the material of stainless steel can play anticorrosion The free end of the main body 5 is recessed axially inward to form a chute 8, the buffer block 7 is placed in the chute 8 and the buffer block 7 can move up and down in the chute 8 in the axial direction; The outer wall of the buffer block 7 is matched and attached to the groove wall of the chute 8; the upper edge of the chute 8 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com