A double-stack self-locking washer

A washer and self-locking technology, applied in the direction of washers, locking fasteners, threaded fasteners, etc., can solve the problems of narrow adaptation surface, slippage, unstable anti-loosening effect, etc., and achieve good occlusal stability, Strong locking ability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

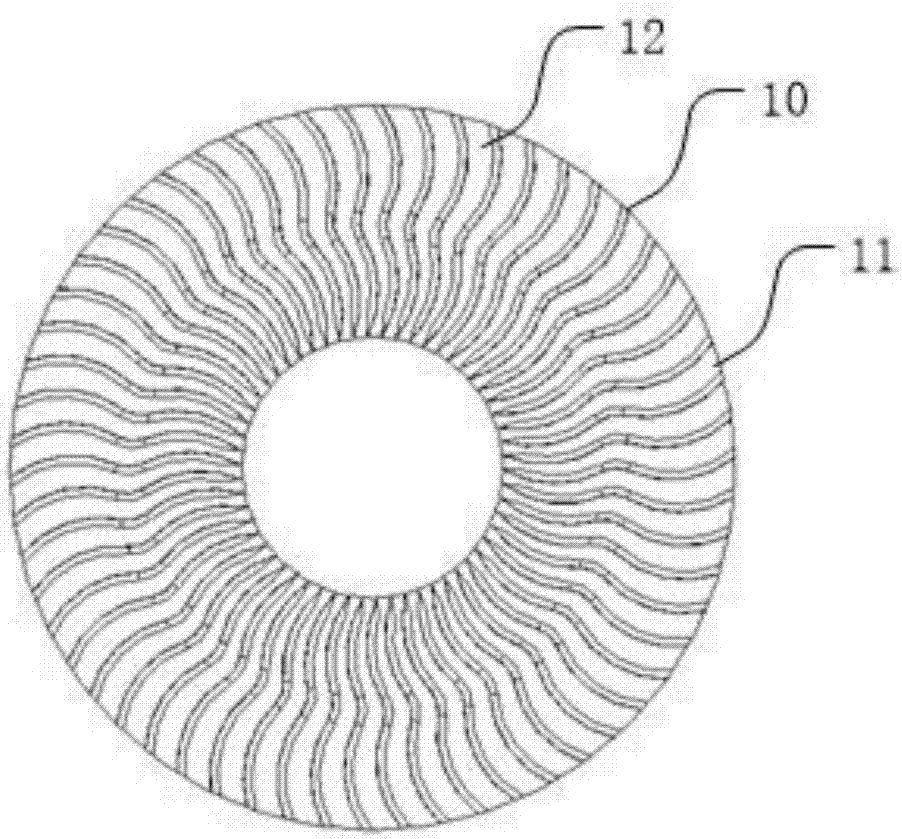

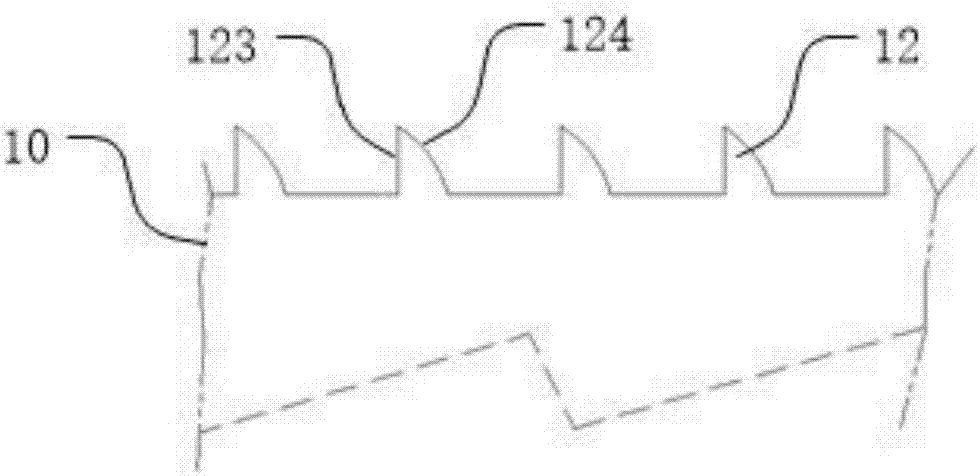

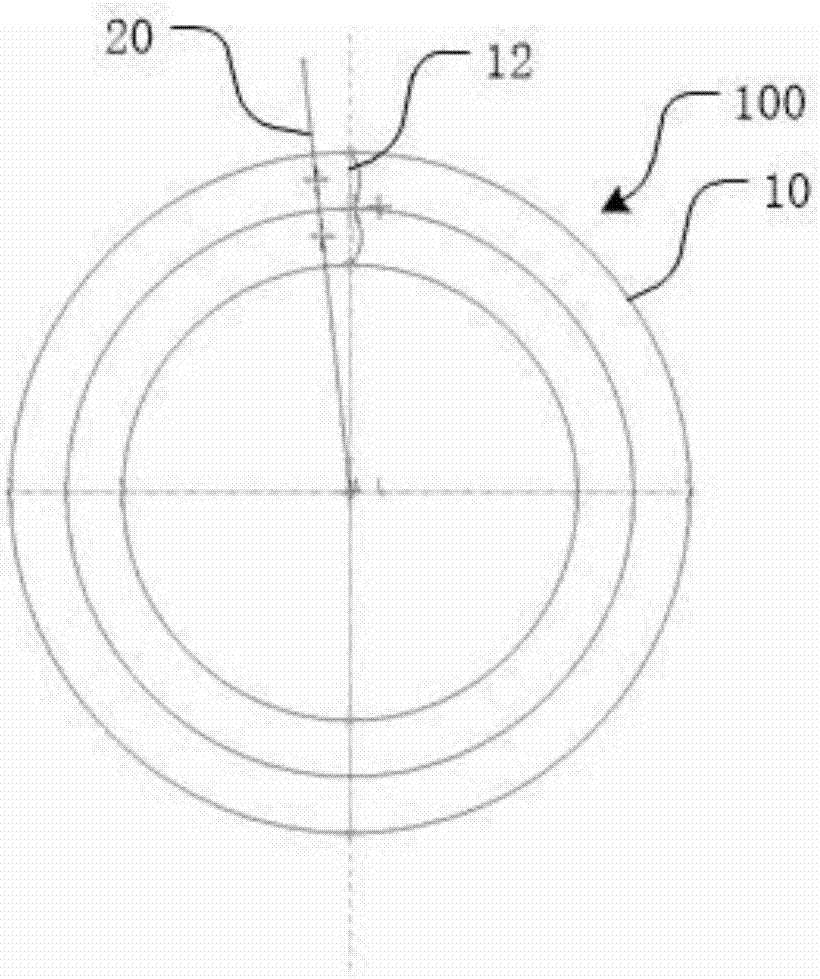

[0021] Such as figure 1 As shown, the double-stacked self-locking washer 100 of an embodiment of the present invention generally includes two sub-washers 10 that engage with each other. One side of the two sub-washers 10 is respectively provided with wedge-shaped large teeth with the center of the circle as the midpoint, and on the other side Radial arc-shaped teeth 12 with the center of the circle as the midpoint are respectively provided. Each arc-shaped tooth 12 is an arc transition from the inner ring edge 14 to the outer ring edge 13 of the sub-washer 10. When in use, the two sub-washers 10 pass through the wedge-shaped large teeth. The end surfaces mesh with each other, and the meshed two sub-washers 10 are bonded together by glue coated on the large tooth surface.

[0022] In this embodiment, the small tooth end surface 11 of the sub-washer 10 in contact with the workpiece surface is optimized from the existing radial straight tooth structure to an arc tooth shape, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com