High-strength wear-resistant rubber shaft sleeve

A wear-resistant, high-strength technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low strength, difficult disassembly of the shaft sleeve, and affecting the effect of the use of the shaft sleeve, etc., to achieve occlusal stability Good, stable performance, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

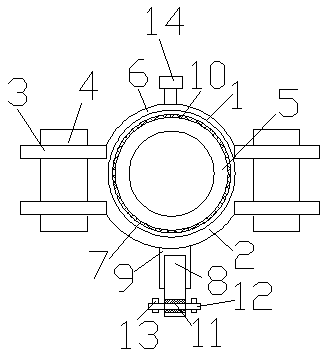

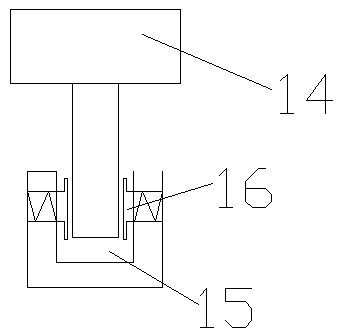

[0015] The high-strength wear-resistant rubber bushing is provided with an upper sleeve 1 and a lower sleeve 2, a connecting platform 3 is arranged between the upper sleeve 1 and the lower sleeve 2, and a fastening device 4 is arranged on the connecting platform 3, and the upper sleeve 1 and the lower sleeve 2 are provided with an inner sleeve 5, the inside of the inner sleeve 5 is provided with a press-fit cavity 6, a press-fit ring 7 is arranged in the press-fit cavity 6, and a support is provided on the lower side of the lower sleeve 2 Bar 8, a protective cover 9 is arranged between the support bar 8 and the lower cover 2.

[0016] The inner sleeve 5 is a high wear-resistant rubber sleeve, and the pressing ring 7 is provided with a reinforcement net 10 .

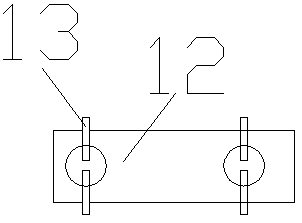

[0017] The protective cover 9 is provided with internal threads, the support bar 8 is provided with external threads, and the protective cover 9 and the support bar 8 are threadedly engaged.

[0018] A limiting hole 11 i...

Embodiment 2

[0021] The high-strength wear-resistant rubber bushing is provided with an upper sleeve 1 and a lower sleeve 2, a connecting platform 3 is arranged between the upper sleeve 1 and the lower sleeve 2, and a fastening device 4 is arranged on the connecting platform 3, and the upper sleeve 1 and the lower sleeve 2 are provided with an inner sleeve 5, the inside of the inner sleeve 5 is provided with a press-fit cavity 6, a press-fit ring 7 is arranged in the press-fit cavity 6, and a support is provided on the lower side of the lower sleeve 2 Bar 8, a protective cover 9 is arranged between the support bar 8 and the lower cover 2.

[0022] The inner sleeve 5 is a high wear-resistant rubber sleeve, and the pressing ring 7 is provided with a reinforcement net 10 .

[0023] The protective cover 9 is provided with internal threads, the support bar 8 is provided with external threads, and the protective cover 9 and the support bar 8 are threadedly engaged.

[0024] A limiting hole 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com