Horizontally-opposed-cylinder, horizontally-opposed-piston and two-stroke homogeneous compression-ignition engine and generators

A horizontally opposed piston, horizontally opposed technology, applied in the direction of machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose of the present invention and the advantage of the motor of the invention simpler and more obvious, the details will be further described below in conjunction with specific embodiments:

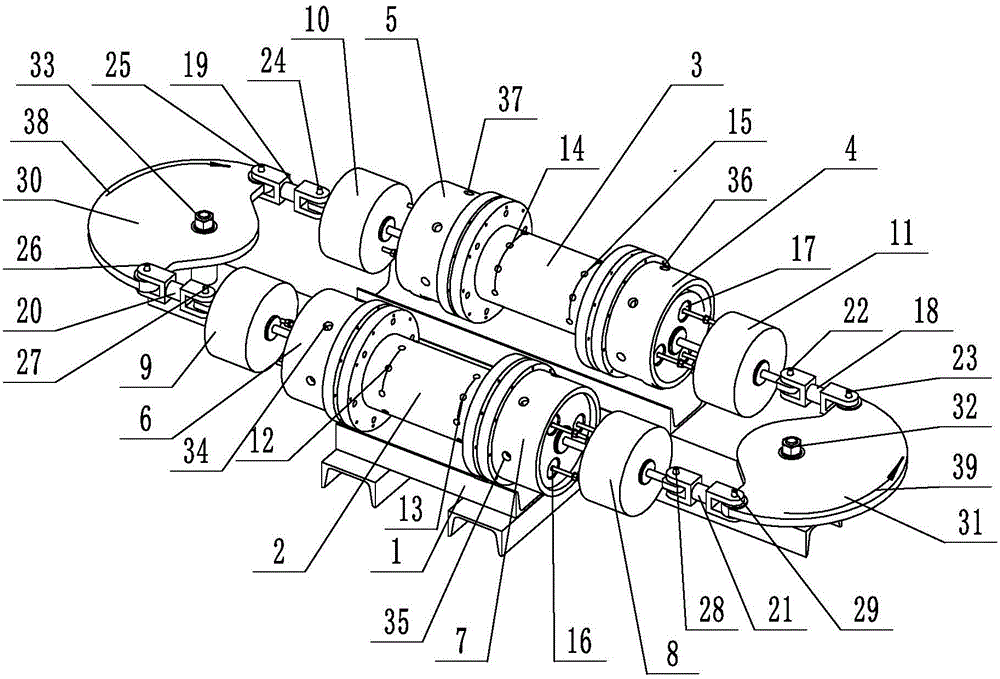

[0019] Such as figure 1 As shown in the structural schematic diagram of the embodiment: it is a horizontally opposed cylinder, a horizontally opposed piston, a two-stroke combustible multiple liquid and gas fuels, a homogeneous compression ignition engine of the present invention and its characteristics of using a linear generator to generate electricity and output electric energy outwards That is, it includes the rack of the whole machine (such as figure 1 Mark 1 in the above, the two cylinders fixed on the rack horizontally (such as figure 1 Marks 2 and 3 in the two cylinders, according to the two rotation direction marks of the two semicircular rocker mechanisms at the two ends of the two cylinders (such as figure 1 The sign 38,39 in the mark) the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com