Engine and piston cooling nozzle assembly

A technology of piston cooling nozzles and assemblies, which is applied in the cooling of engines, engine components, machines/engines, etc., can solve the problems of excessive cooling and cooling of pistons, adverse engine performance, etc., and achieve the effect of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] One of the cores of the present invention is to provide a piston cooling nozzle assembly, so as to properly cool the pistons of the engine, thereby ensuring efficient operation of the engine.

[0034] Another core of the present invention is to provide an engine using the above-mentioned piston cooling nozzle assembly.

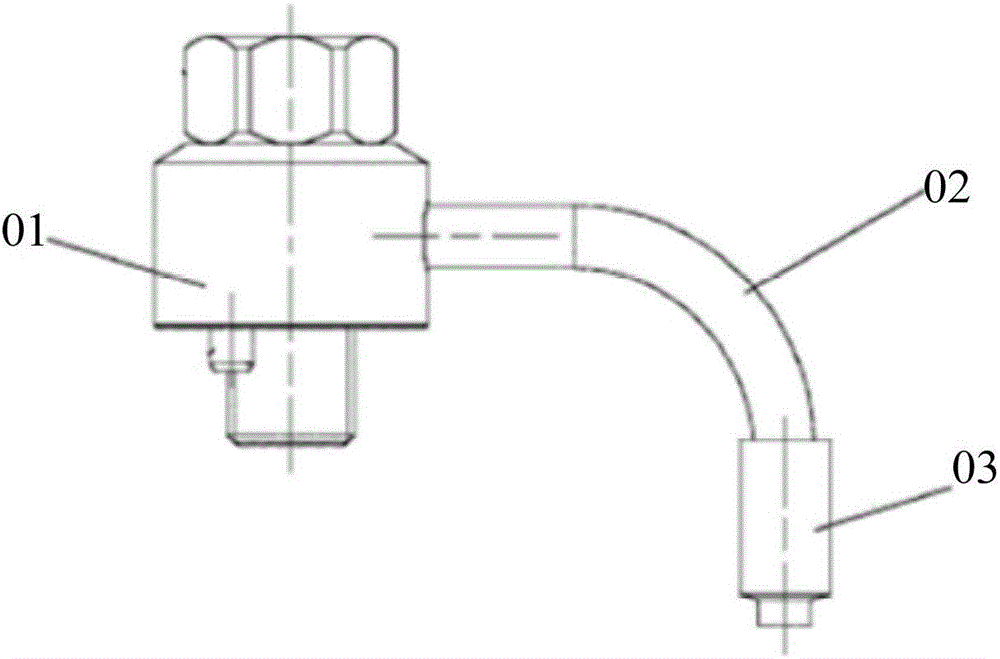

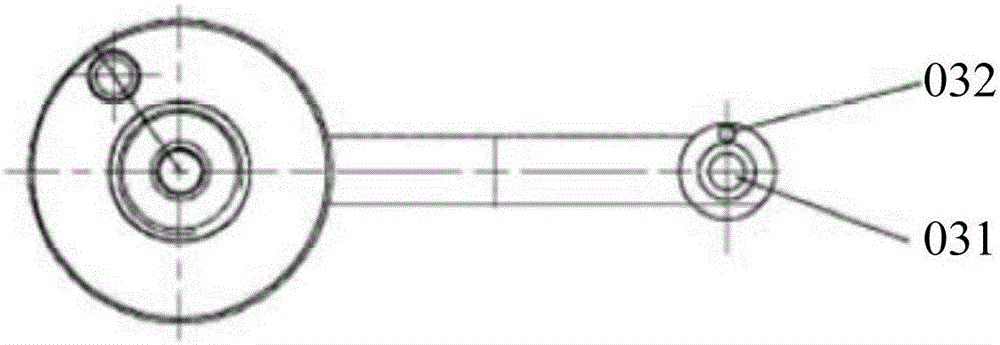

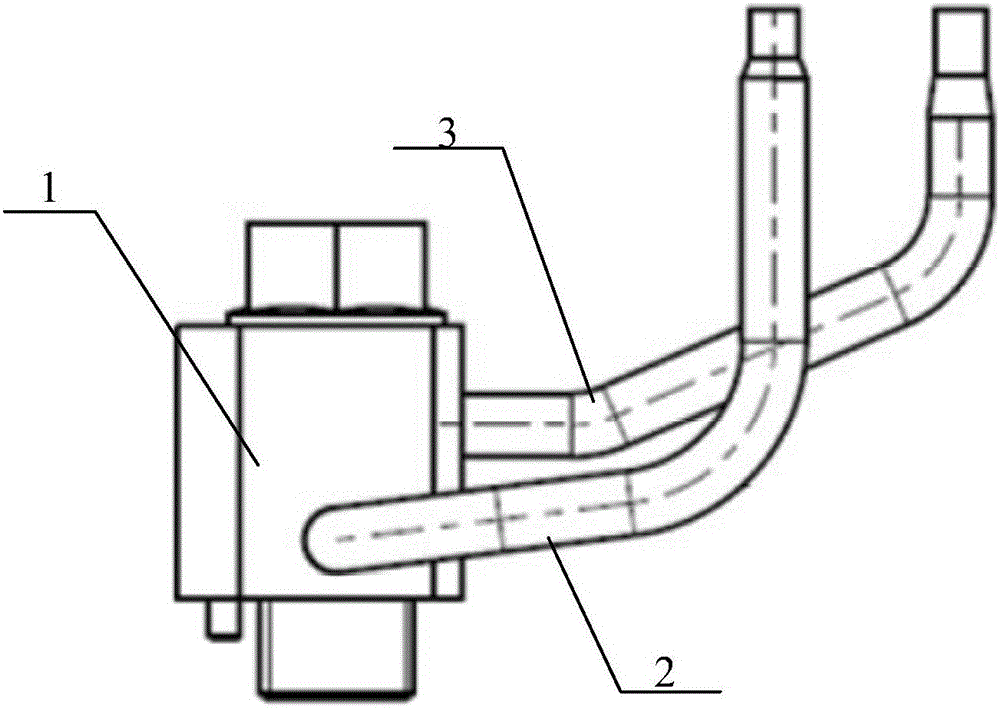

[0035] The piston cooling nozzle assembly disclosed in the embodiment of the present invention includes a base body 1 and a plurality of nozzle units arranged on the base body 1, and each nozzle unit is used to cool different positions of the piston. According to the technology, the core improvement point of the piston cooling nozzle assembly is that as the oil pressure increases, the number of individual nozzles that are opened gradually increases; as the oil pressure decreases, the number of individual nozzles that are opened gradually decreases.

[0036] Those skilled in the art are well aware that the level of engine oil pressure is directly proport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com