Ultrafiltration filter for engine oil as well as filter element and filter paper

A filter and oil technology, applied in the direction of cartridge filter, machine/engine, filtration and separation, etc., can solve the problems of easy blockage and poor filtration effect, and achieve fast removal of dirt, good quality, and avoid filtration. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

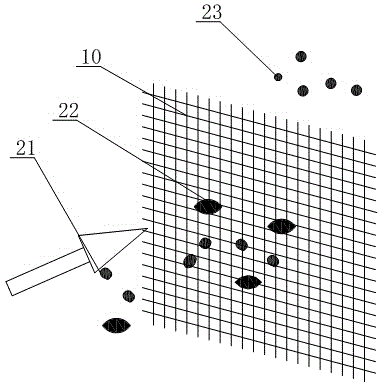

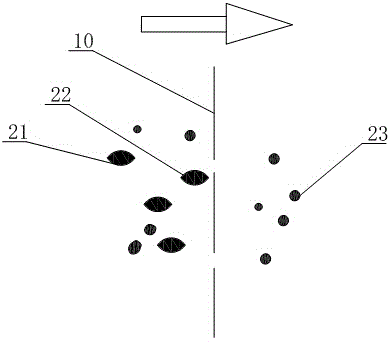

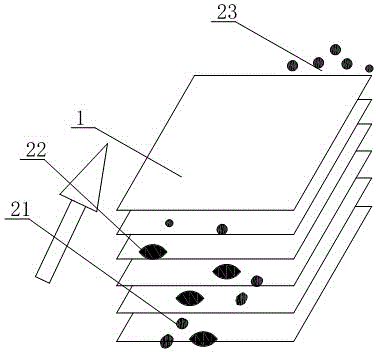

[0026] Figure 5 This is the first embodiment of the oil ultrafiltration filter of the present invention. The top of the filter cylinder 3 is provided with an oil inlet 4, and the cylindrical filter element 2 is installed in the cylinder 3. The filter element 2 of this embodiment is composed of Several layers of filter paper 1 are stacked. The filter paper 1 has a circular ring shape. The through hole in the middle part is stacked to form a cylindrical central hole 6. The central hole 6 communicates with the oil outlet 5 at the bottom of the cylinder 3. When working, the dirty oil 21 enters from the top oil inlet 4 and is distributed to the periphery of the cylinder 3 through the oil distribution channel. Under a certain pressure, the dirty oil 21 changes from a vertical flow state to a horizontal flow state, and passes through a layer of filter paper. Gap channels between slices. Using the above filtering principle, the impurities 22 in the dirty engine oil 21 are trapped in t...

Embodiment 2

[0028] Image 6 This is the second embodiment of the oil ultrafiltration filter of the present invention. The top of the filter cylinder 3 is provided with an oil outlet 5, the center of the cylinder 3 is provided with an oil inlet pipe 7, and the oil inlet pipe 7 is at a certain There are several oil distribution holes 8 on the height. The cylindrical filter element 2 is installed in the cylinder 3 and fixed on the central oil inlet pipe 7. In this embodiment, the filter element 2 is a disc-shaped filter paper 1 roll, such as Image 6 As shown, the filter element 2 is composed of six disc paper rolls, divided into three groups, and the outer circumference of two adjacent paper rolls in each group is provided with a sleeve 9 to isolate the external oil outlet channel; each group An oil inlet gap 11 is provided between the two adjacent paper reels, and the position of the oil inlet gap 11 is set exactly at the height of the oil distribution hole 8 on the oil inlet pipe 7. An o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com