Construction method of spherical warehouse

A construction method and spherical technology, applied in the field of storage warehouses, can solve the problems such as the poor fit between the steel mesh structure and the thermal insulation layer, waste materials, and affect the quality, etc., and achieve the effects of convenient installation, reduction in consumption, and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

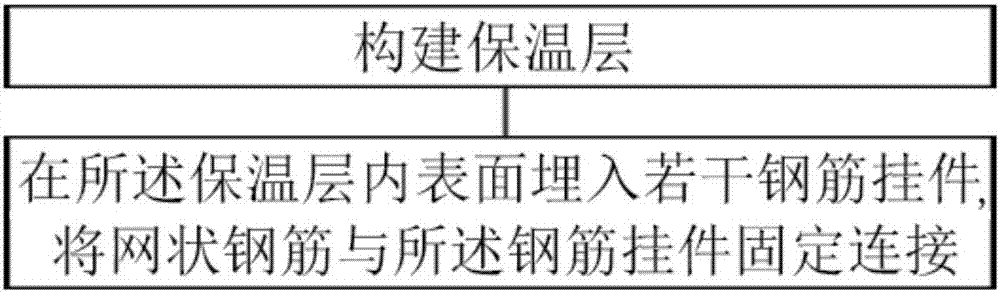

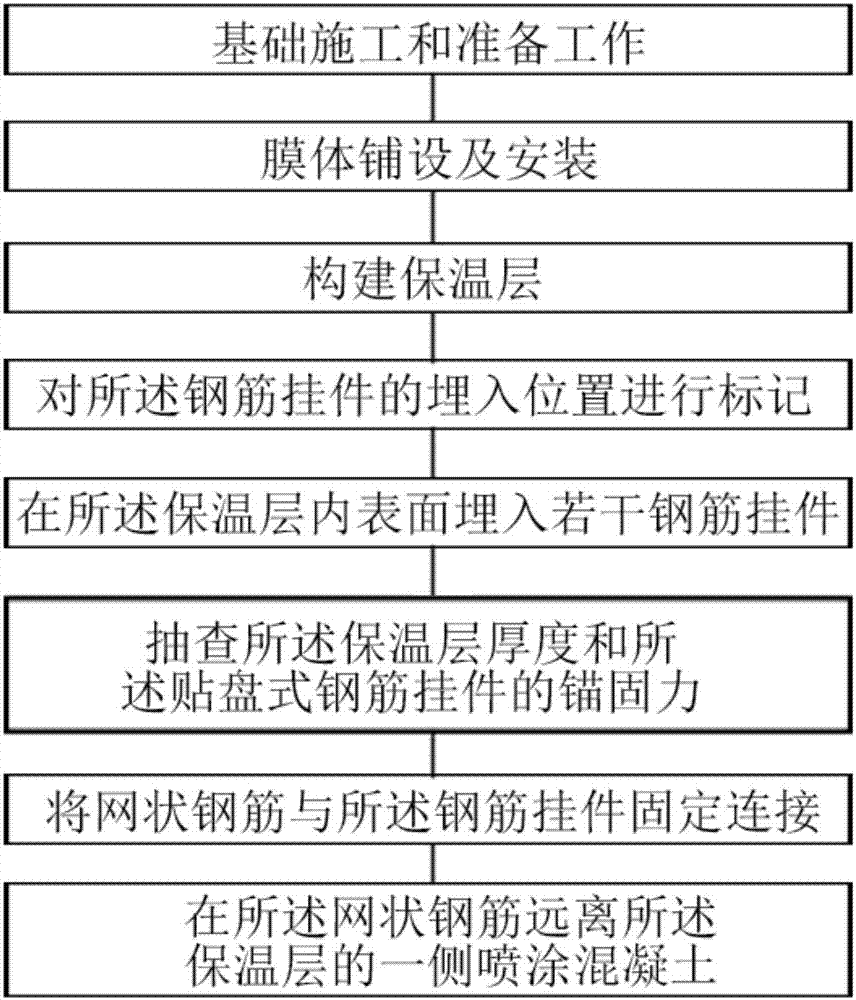

[0046] like figure 1 As shown in the figure, this embodiment provides a construction method for a spherical warehouse, which includes: the step of constructing a thermal insulation layer; after the step of constructing the thermal insulation layer, several steel bar pendants are embedded on the inner surface of the thermal insulation layer, The steel bar pendant is fixedly connected.

[0047] In detail, as figure 2 As shown in the figure, after the steps of foundation construction and preparation, the steps of laying and installing the membrane body, and the step of constructing the thermal insulation layer, the steps include: burying several steel bar pendants on the inner surface of the thermal insulation layer; and spraying concrete on the side of the reticulated steel bar away from the thermal insulation layer.

[0048] In the construction method of the spherical warehouse provided in this embodiment, by using the reinforcing bar pendant to fix the reinforcing bars, the...

Embodiment 2

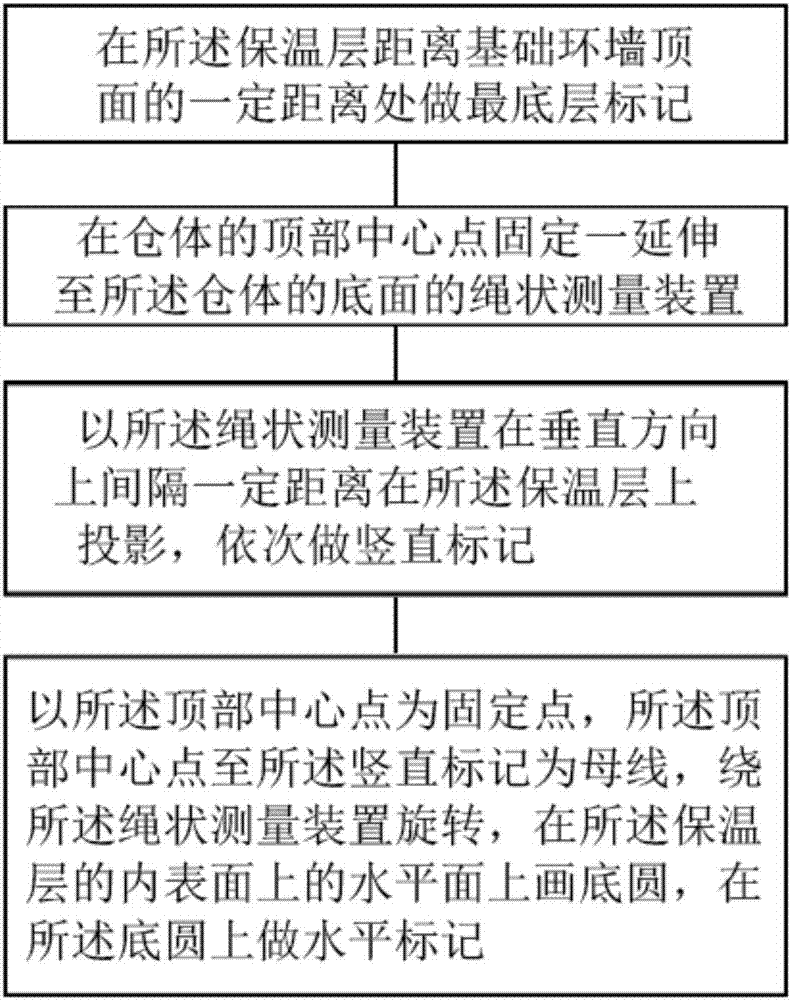

[0050] further, as figure 2 As shown, this embodiment is based on the above-mentioned embodiment 1, before the inner surface of the thermal insulation layer is embedded with the steel bar pendant, the position where the steel bar pendant is embedded in the heat preservation layer is marked, and the steel bar pendant is installed at the marked position; image 3 As shown, in this embodiment, the steps of marking the position of the embedded thermal insulation layer of the steel bar pendant include: (1) marking the bottom layer at a certain distance between the thermal insulation layer and the top surface of the foundation ring wall; (2) marking the bottom layer on the silo body A rope-shaped measuring device extending to the bottom surface of the silo body is fixed at the top center point of the silo body; (3) the rope-shaped measuring device is projected on the insulation layer at a certain distance in the vertical direction, and vertical marks are made in turn; and (4) the si...

Embodiment 3

[0053] further, as figure 2 As shown, on the basis of the above-mentioned Embodiment 1 or 2, after the step of burying the steel bar pendant on the inner surface of the thermal insulation layer, the present embodiment also includes spot checking the thickness of the thermal insulation layer and the anchoring force of the reinforcing bar pendant. In this embodiment, the evenly distributed vertical straight line spacing of the rebar pendants is 700mm, the horizontal straight line spacing is 500mm, and the distance between the bottom steel bar pendant and the top surface of the foundation ring wall is 200mm.

[0054] Spot check the coating thickness on site, and check the coating thickness with a blunt tip probe (the needle tip is blunt iron). At least 90% of the measuring points meet the minimum plane thickness requirements. No less than 15 points should be checked for adhesion strength. The inspection method is the same as that of the adhesion strength test method during test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com