Separation-type prestressed carbon fiber cloth tensioning and adhering device and method

A carbon fiber cloth and a sticking device technology, which is applied in the field of devices for sticking prestressed carbon fiber cloth in a local area, can solve the problem that the quality of sticking and reinforcement and the efficiency of reinforcement construction need to be improved, and the carbon fiber cloth tensioning device is difficult to meet the local reinforcement and on-site construction quality. And efficiency is difficult to guarantee and other problems, to achieve the effect of improving the tension quality, small structure size, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

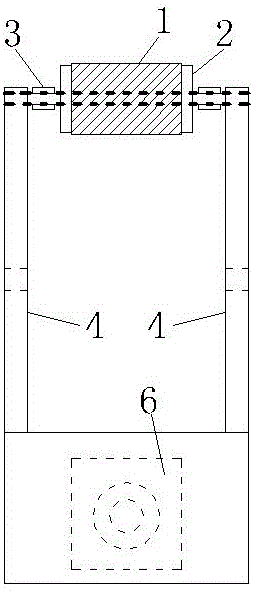

[0033] A separate prestressed carbon fiber cloth stretching-pasting device, as shown in Figure 1, this prestressed carbon fiber cloth stretching-pasting device comprises two sliding roller mechanisms 2, a set of scissors-shaped tensioning mechanism 4, two sets of Thread locking mechanism 3, a jack 5 and a piece of annular carbon fiber cloth 1.

[0034] The sliding roller mechanism 2 includes a sliding bearing 14 and a connecting shaft 15 (as shown in FIG. 4 ). The connecting shaft 15 is inserted into the inner ring 17 of the sliding bearing 14, and its two ends are inserted into the circular through hole of the scissors-shaped tensioning mechanism 4 and the fork 10 of the thread locking mechanism 3, so that the sliding bearing 14, the scissors-shaped tensioning mechanism 4 It is connected with the screw locking mechanism 3 through the connecting shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com