Building method for space truss with spiral ball adjusting and supporting unit

A technology of supporting units and spaces, which is applied in the direction of architecture and building construction, and can solve problems such as difficult adjustments, complex and difficult construction of space grid structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

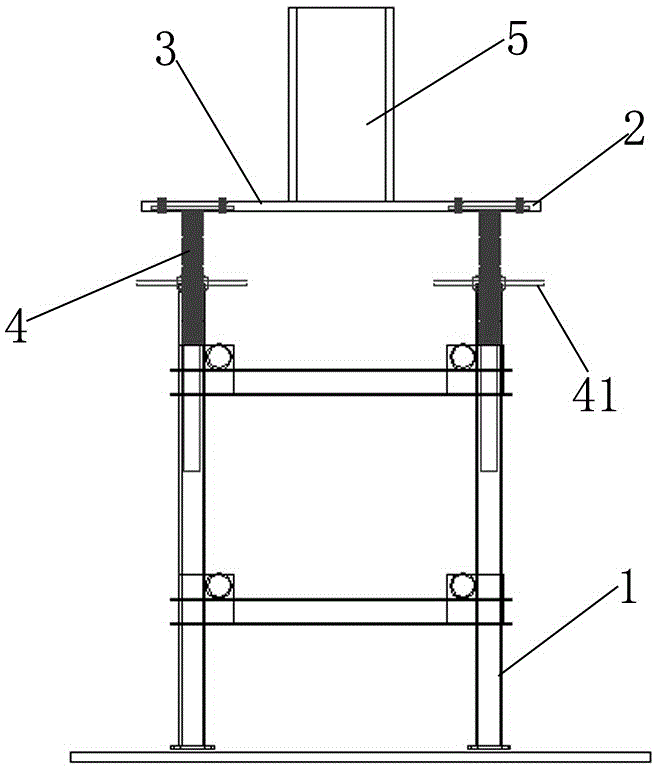

[0016] See attached picture. In this embodiment, taking the two-story grid structure as an example, the construction of the space grid structure is carried out through the following steps: 1) Assembling the ball-spinning adjustment support unit, the ball-spinning adjustment support unit includes steel pipe scaffolding 1, jacking 2 and The steel plate 3, the jacking 2 and the steel plate 3 are connected by bolts to form a detachable supporting platform frame. The lower end of the jacking 2 is a threaded screw 4. The working layer of the scaffold is provided with vertical and longitudinal internal threaded steel pipes, and the screw 4 is screwed into the scaffolding steel pipe Inside, the scaffolding and the jacking bracket form an adjustable movable connection; the steel plate is provided with a cylindrical support steel pipe 5 to support the ball joint; the screw rod is provided with a rotating handle 41;

[0017] 2) Divide the space grid structure into units, and divide the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com