Preparation apparatus and method of lithium niobate crystal nano domain structure

A preparation device, a technology for lithium niobate, applied in the directions of crystal growth, nanotechnology, chemical instruments and methods, etc., can solve the problems of uneven sides of the microdomain structure, poor continuity, strong light scattering, etc., to promote development and application. , to achieve batch, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the lithium niobate crystal nano-domain structure provided by the present invention is mainly divided into three steps: first, constructing a domain wall structure in the lithium niobate crystal; second, heat-treating the sample; third, performing two steps on the sample secondary polarization. Specifically, the following steps are included:

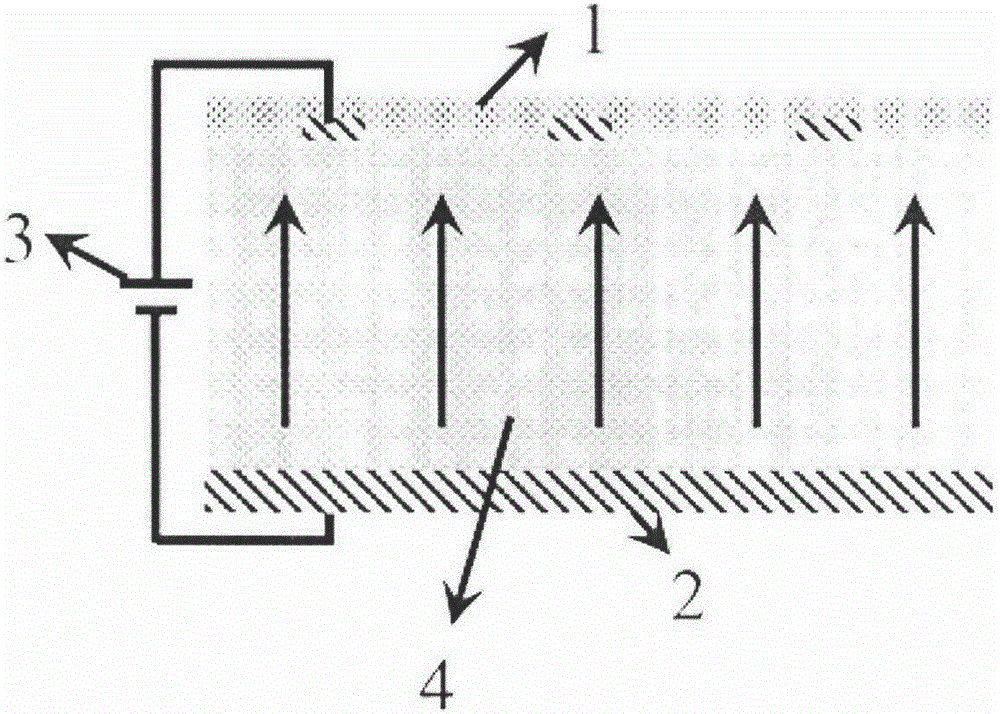

[0029] Step (1): Polarized regions with opposite polarization directions are constructed in the lithium niobate crystal by using a polarization technique, thereby forming a domain wall structure in the lithium niobate crystal.

[0030] Step (2): placing the lithium niobate crystal in a high-temperature furnace for heat treatment.

[0031] Step (3): performing secondary polarization on the heat-treated lithium niobate crystal.

[0032] The above steps will be explained in detail below. Specifically include the following main steps:

[0033]Wherein, the lithium niobate crystal described in step (1) is a...

Embodiment 1

[0051] The lithium niobate crystal used in this embodiment is Z tangential doped magnesium 5mol% lithium niobate crystal with the same composition, the crystal diameter is 10 mm, and the thickness is 500 μm. The corresponding forward inversion voltage is 6.5kV / mm, and the back inversion voltage is 4.2kV / mm.

[0052] The specific implementation steps are:

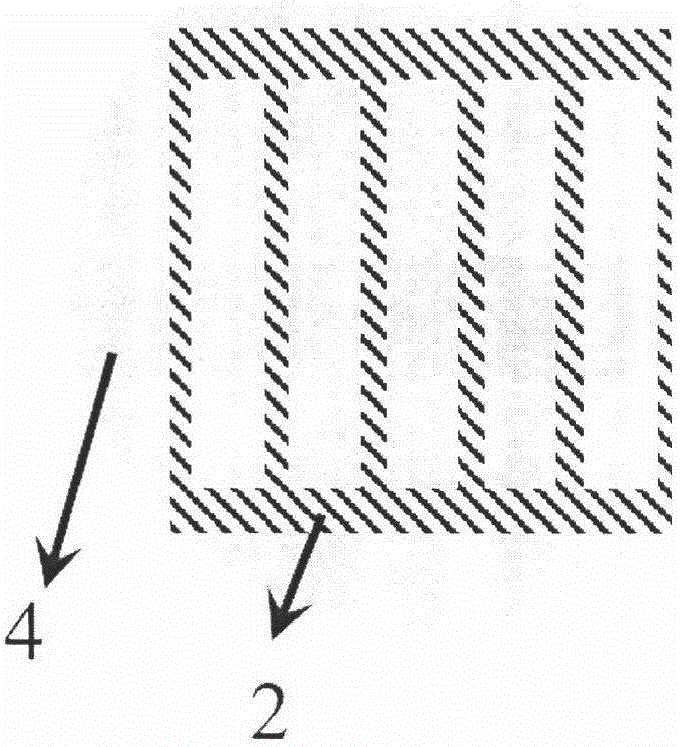

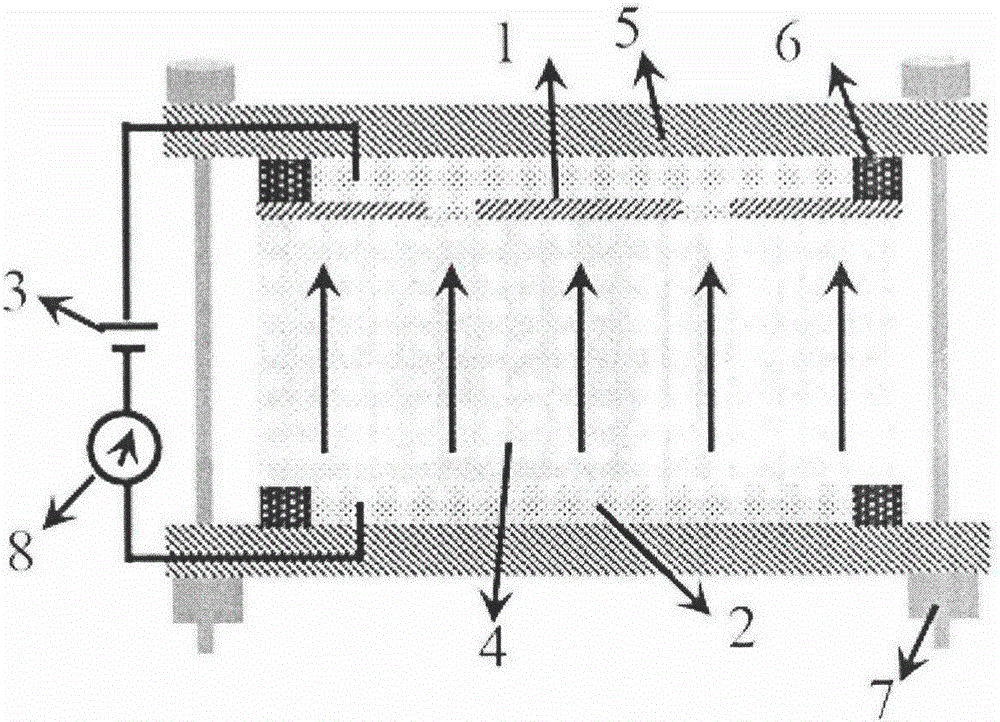

[0053] (1) Construct a periodic poled structure in the sample by using a commonly used liquid electrode polarization device. The liquid electrode polarization device used in this example is as Figure 2a shown. First, the +Z surface of the crystal is plated with such Figure 2b For the photoresist pattern shown in the figure, the photoresist is made of polyimide with a thickness of 2 μm. in, Figure 2d The blank area in the middle is the electrode area, and the size of the electrode is 46 μm×5.4 μm. The distance between adjacent electrodes is 20 μm, and the long direction of the electrodes needs to be along the Y-axis ...

Embodiment 2

[0058] Different from Example 1, Example 2 will use the forward polarization technique to prepare the nano-domain structure.

[0059] The lithium niobate crystal used in this embodiment is Z tangential doped magnesium 5mol% lithium niobate crystal with the same composition, the crystal diameter is 10 mm, and the thickness is 500 μm. The corresponding forward inversion voltage is 6.5kV / mm, and the back inversion voltage is 4.2kV / mm.

[0060] The specific implementation steps are:

[0061] (1), with the step (1) in embodiment 1. First, the +Z surface of the crystal is plated with such Figure 2b For the photoresist pattern shown in the figure, the photoresist is made of polyimide with a thickness of 2 μm. in, Figure 2d The blank area in the middle is the electrode area, and the size of the electrode is 46 μm×5.4 μm. The distance between adjacent electrodes is 20 μm, and the long direction of the electrodes needs to be along the Y-axis direction of the crystal. Then, paste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com