Preparation device for single-crystal graphite material

A technology of graphite material and preparation device, which is applied in the directions of polycrystalline material growth, single crystal growth, crystal growth, etc., can solve the problems of deviation of graphite characteristics, affecting the physical and chemical morphology of graphite flake crystals, etc., and achieves increased use and simple method. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

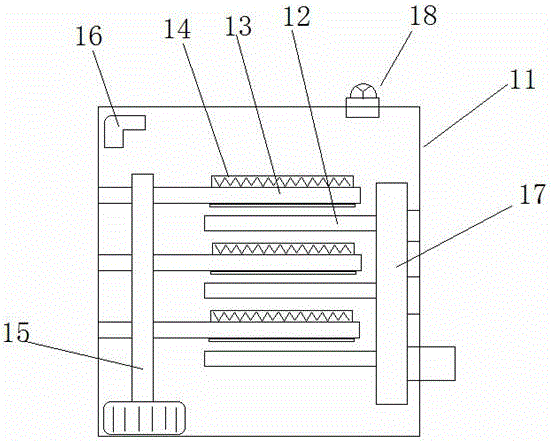

[0022] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] As shown in the figure, a kind of single crystal graphite material preparation device of the present invention comprises reaction furnace 11, and described reaction furnace 11 is provided with multi-layer interlayer 12 for placing graphite sheet, and described interlayer 12 is fixed on reaction furnace 11. On the inner wall of the furnace 11, a plurality of wear plates 13 corresponding to the interlayer 12 are also arranged on the inner wall of the reaction furnace 11;

[0024] The wear plate 13 is fixed on the inner wall of the reaction furnace 11, the wear plate 13 is partly located above the interlayer 12, and the surface of the wear plate 13 facing the interlayer 12 has friction particles;

[0025] A resistance heater 14 is provided on the other side of the wearing plate 13;

[0026] The connecting wear plate 13 is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com