Mammoth converter lining and construction method thereof

A technology for large-scale converters and furnace linings, which can be used in the manufacture of converters and other directions, and can solve the problems of low back-end strength and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

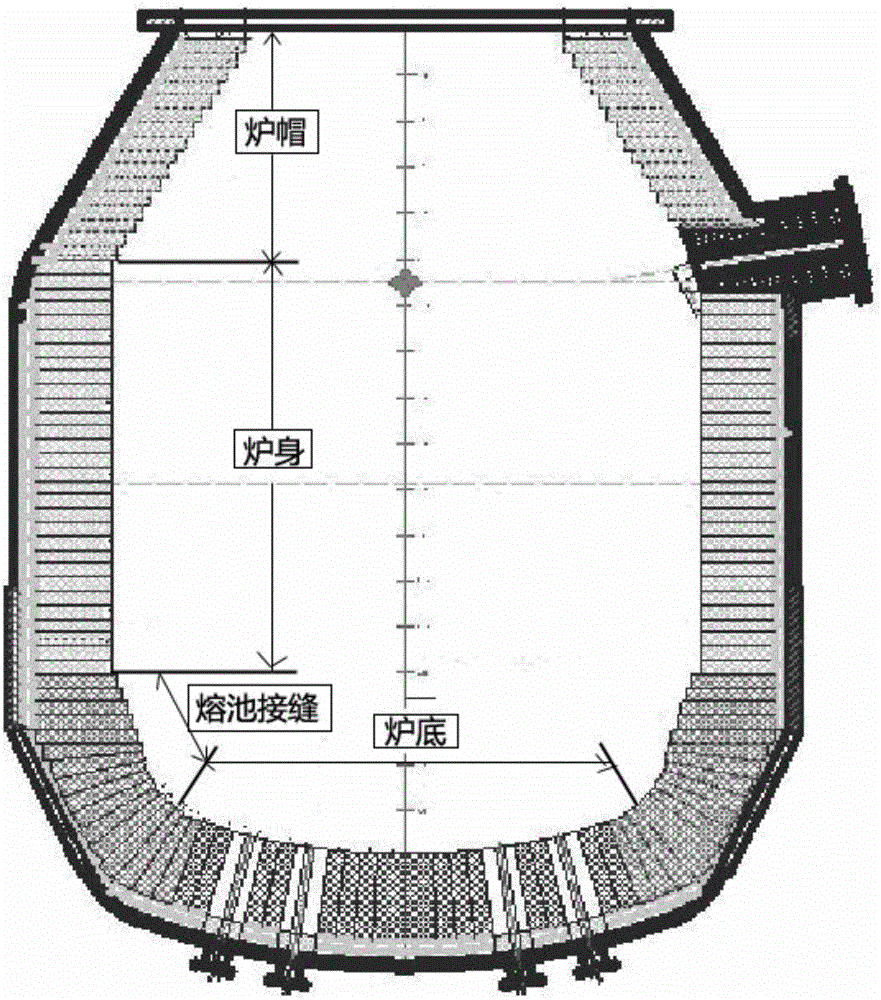

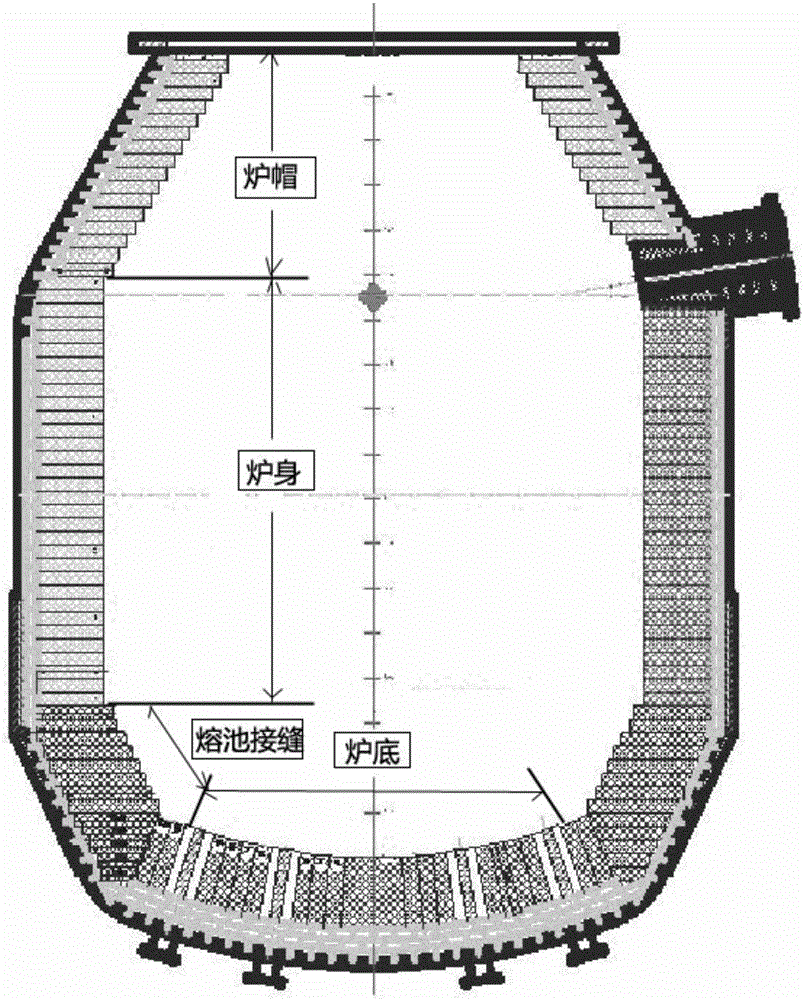

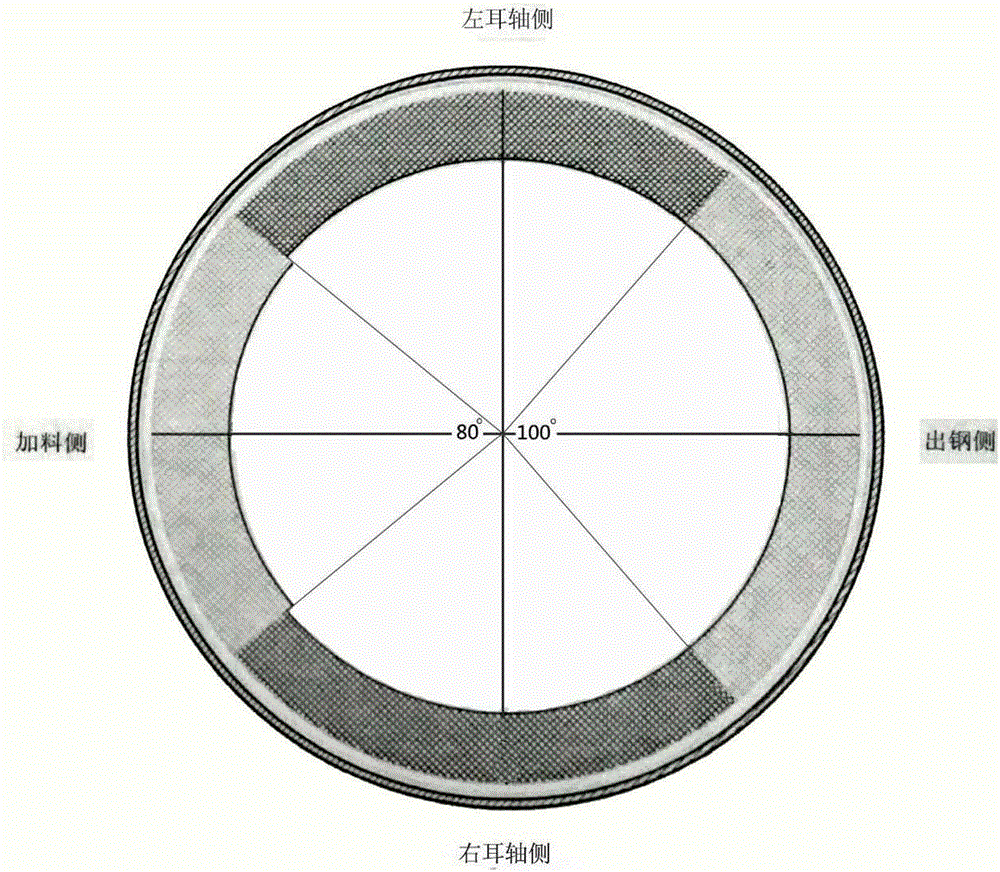

[0043] Such as figure 1 , image 3 , Figure 5 As shown, a large-scale converter lining includes furnace bottom, molten pool joint, furnace body and furnace cap. The furnace bottom, molten pool joint, furnace body and furnace cap include permanent Layer, middle packing layer, working layer, the working layer is made of magnesia carbon refractory bricks, and the working layer includes the feeding side working layer connected as a whole structure in the horizontal direction, the left trunnion side working layer, and the tapping hole side The working layer and the working layer on the right trunnion side; the working layer at the joint of the molten pool on the left trunnion side and the right trunnion side is made of MT-18A magnesia-carbon bricks, and the length of the MT-18A magnesia-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com