Tobacco essence capable of improving quality of cigarettes and preparation method of tobacco essence

A technology for tobacco flavor and quality, which is applied in the preparation of tobacco, essential oils/spice, tobacco, etc., can solve problems such as reducing the quality of cigarettes, smoke turbidity, and oral residues, and achieves the improvement of aroma, taste, and irritation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

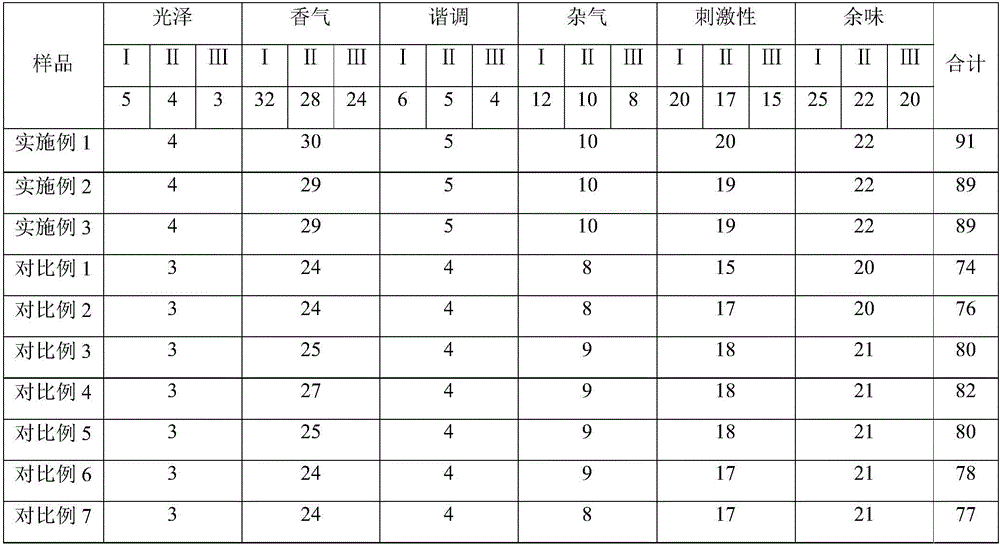

Embodiment 1

[0024] The tobacco flavor in this example is prepared from the following raw materials: Inula extract 18g, rose essential oil 11g, eugenol 11g, citronellol 9g, damascone 9g, malic acid 7g, isoamyl alcohol 7g, Methyl oleate 4g, carvone 4g, geranyl acetate 4g, chamomile flower oil 4g.

[0025] Among them, the extraction method of Inula extract is:

[0026] (1) Crush the washed and dried inula roots through an 80-mesh sieve to obtain inula root powder;

[0027] (2) Mix the inula root powder with 68% ethanol at a material-to-liquid ratio of 29g / L, then add 17% arabinose by mass of the inula root powder to the mixture, and mix the mixture evenly , Ultrasonic extraction is used to obtain the extract, where the ultrasonic extraction conditions are: temperature 68°C, time 100min, power 600W;

[0028] (3) The extract is filtered, and the filtrate is vacuum concentrated by a rotary evaporator at 30°C to a relative density of 1.25 to obtain the Inula extract.

[0029] Mix 7g isoamyl alcohol, 4g ...

Embodiment 2

[0031] The tobacco flavor in this embodiment is prepared from the following raw materials: 16g of inula extract, 10g of rose essential oil, 10g of eugenol, 8g of citronellol, 8g of damascone, 6g of malic acid, 6g of isoamyl alcohol, Methyl oleate 3g, carvone 3g, geranyl acetate 3g, chamomile flower oil 3g.

[0032] Among them, the extraction method of Inula extract is:

[0033] (1) Crush the washed and dried inula roots through an 80-mesh sieve to obtain inula root powder;

[0034] (2) Mix the inula root powder with 65% ethanol at a material-to-liquid ratio of 28g / L, then add 14% arabinose by mass of the inula root powder to the mixture, and mix the mixture evenly , The extraction liquid is obtained by ultrasonic extraction, wherein the ultrasonic extraction conditions are: temperature 65°C, time 90min, power 500W;

[0035] (3) The extract is filtered, and the filtrate is vacuum concentrated by a rotary evaporator at 30°C to a relative density of 1.25 to obtain the Inula extract.

[0...

Embodiment 3

[0038] The tobacco flavor in this example is prepared from the following raw materials: 20g of inula extract, 12g of rose essential oil, 12g of eugenol, 10g of citronellol, 10g of damascarone, 8g of malic acid, 8g of isoamyl alcohol, Methyl oleate 5g, carvone 5g, geranyl acetate 5g, chamomile flower oil 5g.

[0039] Among them, the extraction method of Inula extract is:

[0040] (1) Crush the washed and dried inula roots through an 80-mesh sieve to obtain inula root powder;

[0041] (2) Mix the inula root powder and 70% ethanol at a material-to-liquid ratio of 30g / L, then add 20% arabinose by mass of the inula root powder to the mixture, and mix the mixture evenly , Ultrasonic extraction is used to obtain the extraction liquid, where the ultrasonic extraction conditions are: temperature 70℃, time 120min, power 700W;

[0042] (3) The extract is filtered, and the filtrate is vacuum concentrated by a rotary evaporator at 30°C to a relative density of 1.25 to obtain the Inula extract.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com