Automobile engine dismantling-free cleaning oil and application thereof

A car engine and cleaning oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of metal surface damage, short cleaning time, engine sequelae, etc., and achieve the effect of prolonging the service life and reducing the fuel consumption of cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

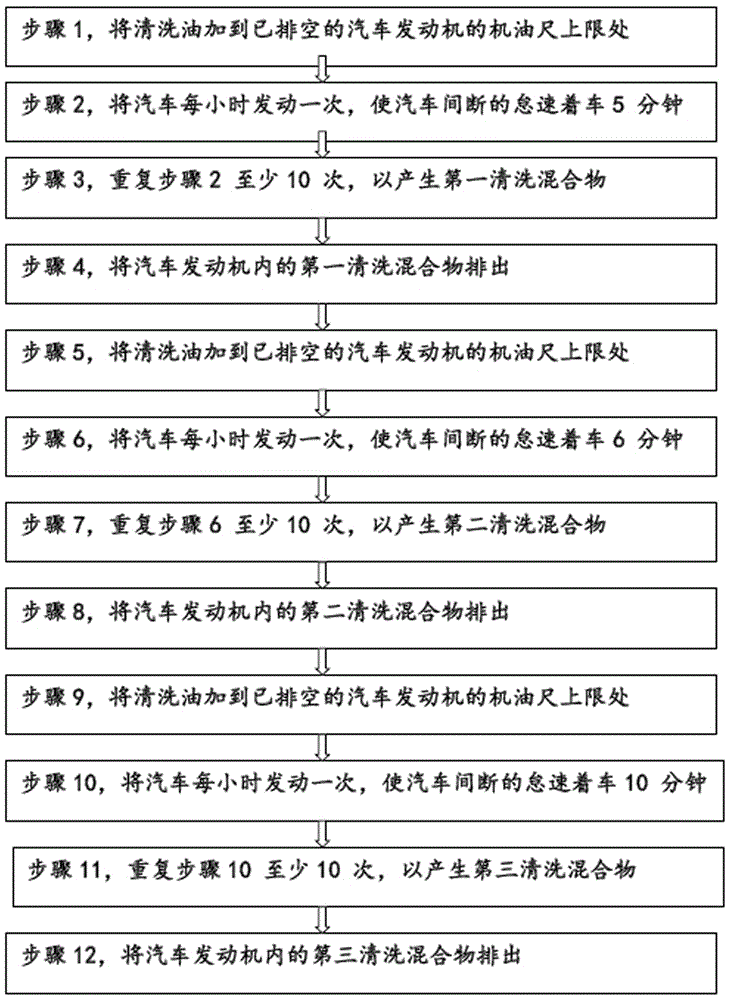

Method used

Image

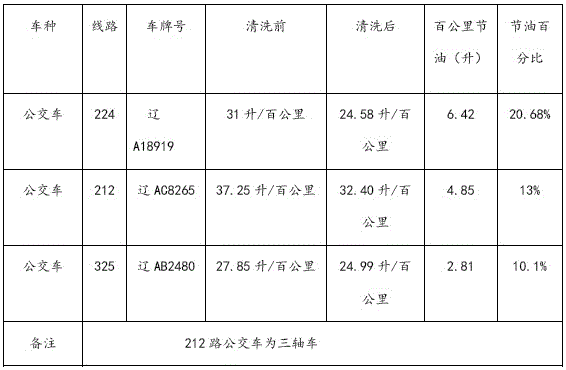

Examples

Embodiment 1

[0041] Automobile engine disassembly-free cleaning oil, by weight percentage, including: 21% kerosene, 0.8% ethanol, 0.6% thickener methacrylic acid, 0.2% corrosion inhibitor cetylamine, 0.6% emulsifying Calcium stearoyl emulsifier, 0.6% anti-wear additive calcium borate, 0.6% metal passivator N.N'-disalicylidene propylenediamine, 0.6% surfactant sodium dodecylsulfonate and 75% oil.

[0042] The specific preparation method is as follows: under normal temperature and pressure, 21% kerosene by weight, 0.8% ethanol, 0.6% thickener methacrylic acid, 0.2% corrosion inhibitor cetylamine, 0.6% emulsified Calcium stearoyl emulsifier, 0.6% anti-wear additive calcium borate, 0.6% metal passivator N.N'-disalicylidene propylenediamine, 0.6% surfactant sodium dodecylsulfonate Mix well with 75% engine oil.

Embodiment 2

[0044] Automobile engine disassembly-free cleaning oil, by weight percentage, including: 15% kerosene, 2.5% ethanol, 1.5% thickener methacrylic acid, 1% corrosion inhibitor cetylamine, 1% emulsifier Calcium stearoyl emulsifier, 1.5% anti-wear additive calcium borate, 1% metal passivator N.N'-disalicylidene propylenediamine, 1.5% surfactant sodium dodecylsulfonate and 75% oil.

[0045] The specific preparation method is as follows: under normal temperature and pressure, 15% by weight of kerosene, 2.5% ethanol, 1.5% thickener methacrylic acid, 1% corrosion inhibitor cetylamine, 1% emulsified Calcium stearoyl emulsifier, 1.5% anti-wear additive calcium borate, 1% metal passivator N.N'-disalicylidene propylenediamine, 1.5% surfactant sodium dodecylsulfonate Mix well with 75% engine oil and serve.

Embodiment 3

[0047] Automobile engine disassembly-free cleaning oil, by weight percentage, including: 18% kerosene, 2.0% ethanol, 0.8% thickener methacrylic acid, 0.9% corrosion inhibitor cetylamine, 0.9% emulsifier Calcium stearoyl emulsifier, 0.8% anti-wear additive calcium borate, 0.8% metal deactivator N.N'-disalicylidene propylenediamine, 0.8% surfactant sodium dodecylsulfonate and 75% oil.

[0048] The specific preparation method is as follows: under normal temperature and pressure, 18% by weight of kerosene, 2.0% ethanol, 0.8% thickener methacrylic acid, 0.9% corrosion inhibitor cetylamine, 0.9% emulsified Calcium stearoyl emulsifier, 0.8% anti-wear additive calcium borate, 0.8% metal deactivator N.N'-disalicylidene propylenediamine, 0.8% surfactant sodium dodecylsulfonate Mix well with 75% engine oil and serve.

[0049] In the above three embodiments, winter engine oil is used for the engine oil in winter, and summer engine oil is used in summer to ensure better cleaning effect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com