Fireproof paint for steel structures and preparation method of fireproof paint

A fireproof coating and steel structure technology, applied in the field of steel structure fireproof coating and steel structure fireproof coating preparation, can solve problems such as damage, burning of fireproof coating film-forming substances, inability to use steel structure fireproof coating, etc. The effect of reducing the amount of fire retardant coating and reducing the total cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A steel structure fireproof coating and a preparation method thereof, the composition ratio of the steel structure fireproof coating includes (mass percentage): 10% of fluoropolymer emulsion, 5% of silicone modified polyacrylate emulsion, 8% of ammonium polyphosphate %, melamine 13% and pentaerythritol 4%, base resin 30%, other additives 30%.

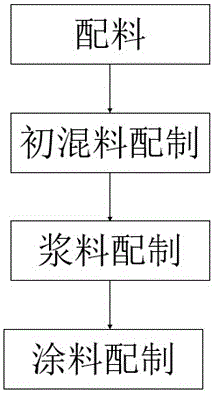

[0019] A preparation method of steel structure fireproof coating, described preparation process is carried out according to the following steps,

[0020] (1) Ingredients: Prepare the ingredients according to the weight of the components of the above-mentioned steel structure fireproof coating;

[0021] (2) Primary mix preparation: Mix the fluorine-containing polymer emulsion and the silicone-modified polyacrylate emulsion in the batching tank evenly;

[0022] (3) Slurry preparation: put the primary mixture prepared in step (2) together with ammonium polyphosphate, melamine, pentaerythritol, and base resin and stir at high speed ...

Embodiment 2

[0025] The rest are the same as in Example 1, except that the composition ratio of the steel structure fireproof coating includes (mass percentage): 17% of fluoropolymer emulsion, 8% of silicone modified polyacrylate emulsion, 10% of ammonium polyphosphate %, 15% melamine and 5% pentaerythritol, 25% base resin, and 20% other additives; in the step (4), the stirring speed is 300r / min, and the grinder grinds 3 times.

Embodiment 3

[0027] The rest are the same as in Example 1, except that the composition ratio of the steel structure fireproof coating includes (mass percentage): 20% of fluoropolymer emulsion, 10% of silicone modified polyacrylate emulsion, 12% of ammonium polyphosphate %, 17% melamine and 6% pentaerythritol, 20% base resin, and 15% other additives; in the step (4), the stirring speed is 400r / min, and the grinder grinds 4 times.

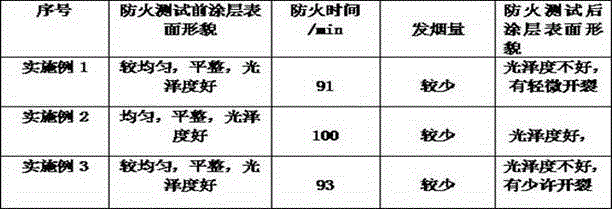

[0028] After the above process steps, the steel structure samples are taken out to be tested:

[0029]

[0030] From the above data, it can be seen that the prepared steel structure fireproof coating has a fireproof time of more than 90 minutes. Adding a flame retardant and smoke suppressant (zinc chloride) and a flame retardant synergist (antimony trioxide), the fireproof coating has a very low smoke emission. Less, the fire performance after the test is not greatly weakened.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com