A smart composite material based on crystal photoinduced phase transition and its preparation method

A technology of composite materials and crystal materials, applied in the direction of coating, etc., can solve the problems of insufficient deformation and complex preparation process of optical-mechanical energy conversion materials, etc., and achieve the effect of simple preparation method, wide application range and easy availability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

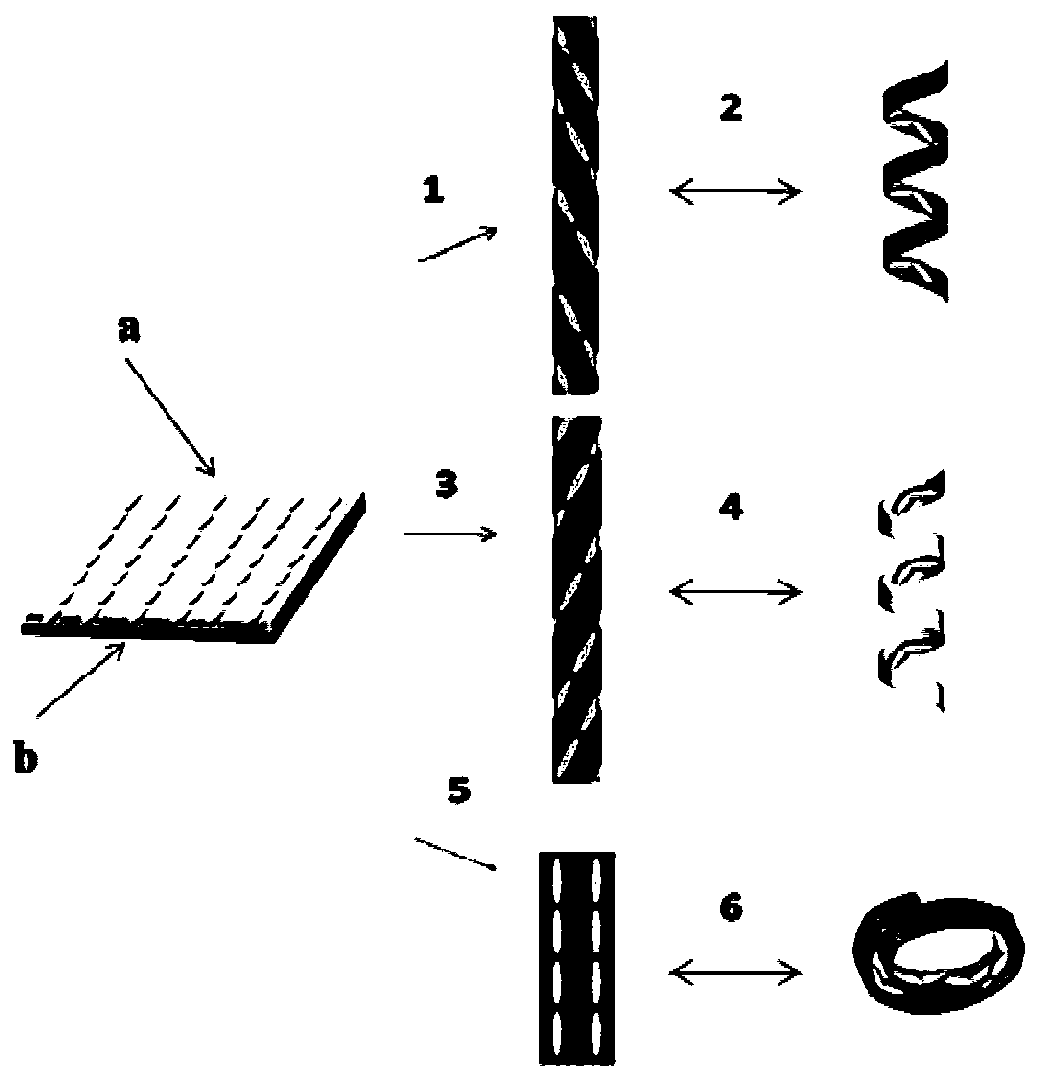

Method used

Image

Examples

Embodiment 1

[0034] 1. Rubbing Orientation of Polymer Substrates:

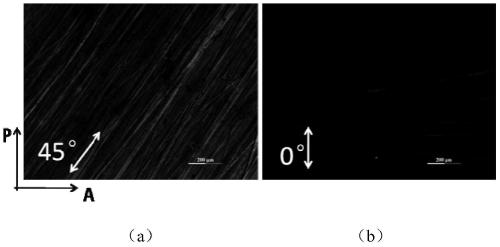

[0035] The low-density polyethylene film is polished with sandpaper to obtain a micro-groove structure. Due to the regular periodic groove structure, the low-density polyethylene film shows periodic light and dark changes under a polarizing microscope, such as figure 2 shown.

[0036] 2. Preparation of composite film:

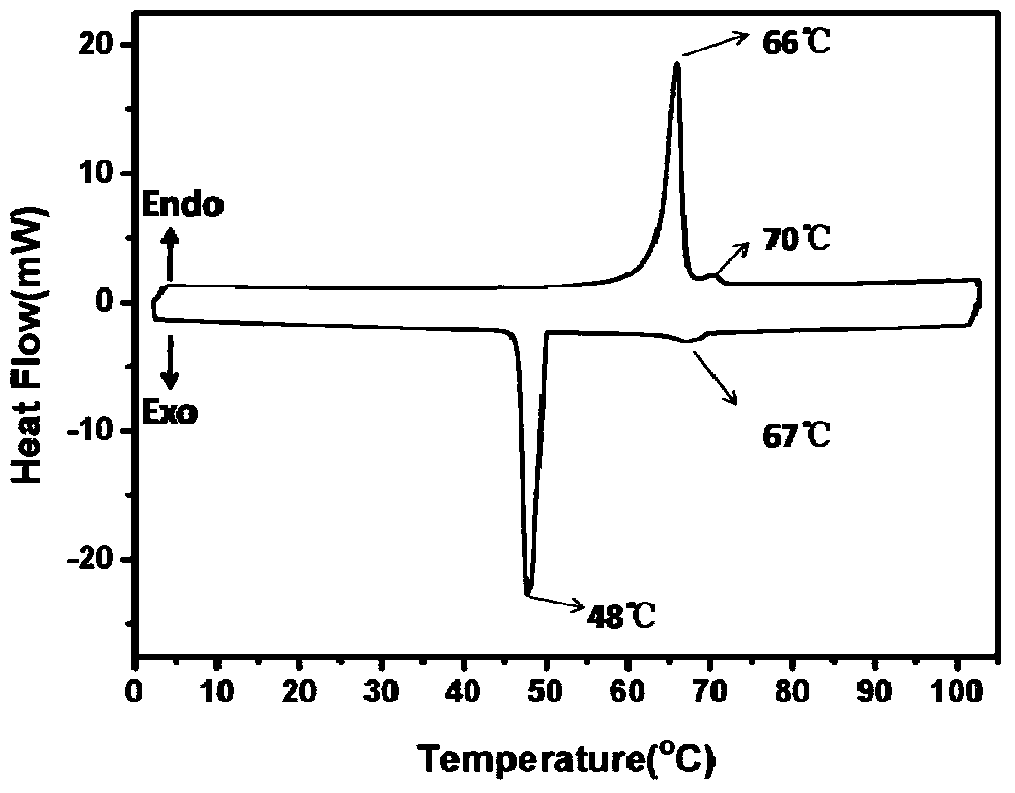

[0037] Synthesize 4,4'-bis(undecyloxy)-3-methylazobenzene crystal, its structural formula is such as formula Ia, take an appropriate amount to prepare a 3wt% acetone solution, and coat it on a low-density polyethylene film , because the liquid crystal temperature of 4,4'-bis(undecyloxy)-3-methylazobenzene crystal is about 67°C, such as image 3 and Figure 4 As shown, it can be seen that the compound is in a crystalline state at room temperature. When heated to a melting point of 66°C, it is a nematic liquid crystal until the clearing point of 70°C, and then becomes an isotropic liquid; during cooling, ...

Embodiment 2

[0042] 1. The rubbing alignment operation of the polyimide substrate is the same as the operation process in Example 1.

[0043] 2. Preparation of composite film:

[0044] Synthesize 4,4'-bis(undecyloxy)-3-ethylazobenzene crystal, the structural formula is shown in formula Ib, take an appropriate amount of 3wt% tetrahydrofuran solution, and coat it on a low-density polyethylene film, During annealing, at the liquid crystal temperature of 4,4'-bis(undecyloxy)-3-ethylazobenzene crystal, other operations are the same as in Example 1.

[0045]

[0046] 3. Composite thin film light-driven phenomenon:

[0047] The light-driven phenomenon of the composite thin film is the same as in Example 1.

Embodiment 3

[0049] 1. The rubbing orientation operation of the low-density polyethylene substrate is the same as the operation process in Example 1.

[0050] 2. Preparation of composite film:

[0051] Synthesize 4,4'-bis(undecyloxy)-3-propyl azobenzene crystal, its structural formula is shown in formula Ic, take an appropriate amount to prepare a 3wt% tetrahydrofuran solution, and coat it on a low-density polyethylene film , above the melting point temperature of 4,4'-bis(undecyloxy)-3-propylazobenzene crystal during annealing, other operations are the same as in Example 1.

[0052]

[0053] 3. Composite thin film light-driven phenomenon:

[0054] The light-driven phenomenon of the composite thin film is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com