Carriage follower mechanism

A sliding frame and frame technology, which is used in motor vehicles, conveyor objects, transportation and packaging, etc., can solve the problems that aerial conveyors can only be placed on the ground static conveyors, and the body cannot be accurately placed, and achieves a high degree of automation. Safe and reliable work, process reversible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

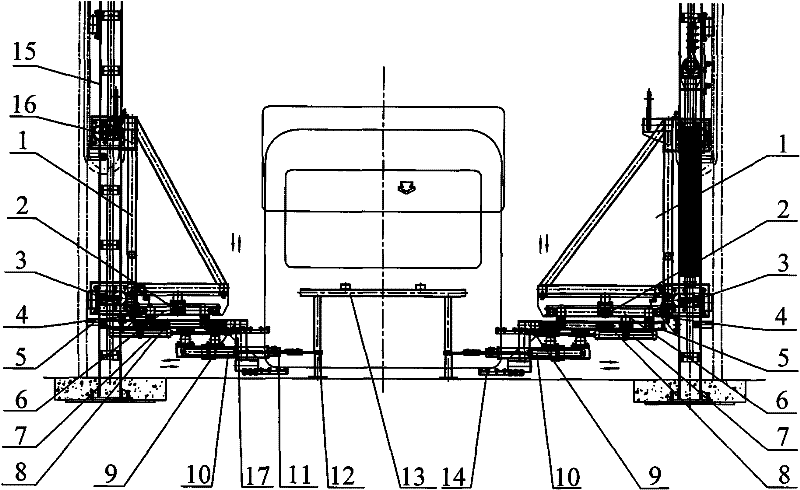

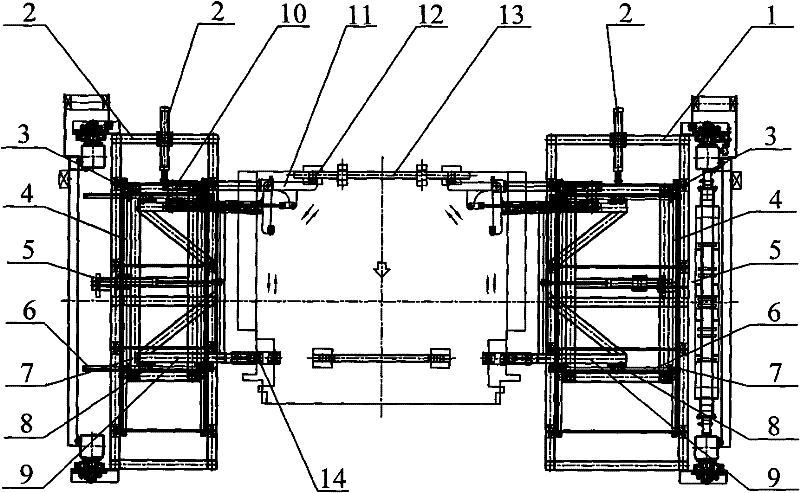

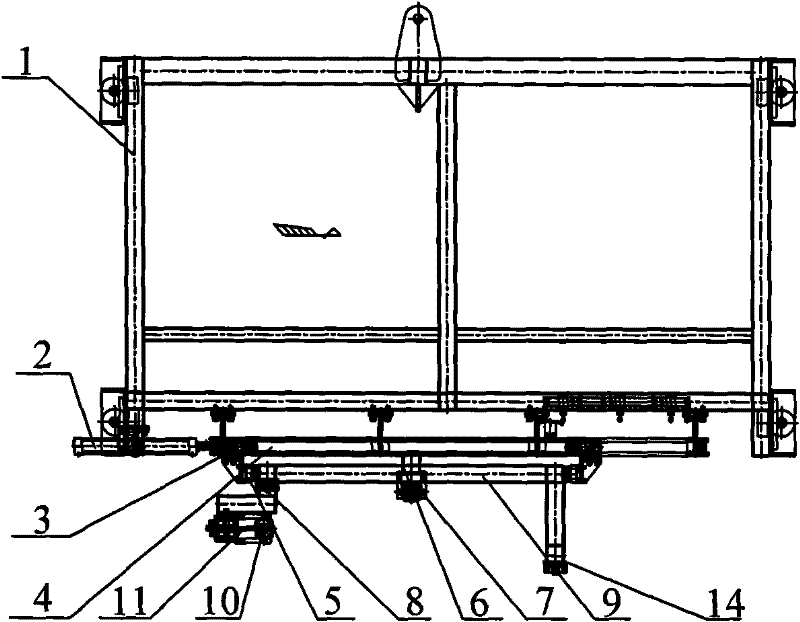

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0013] As shown in the figure: the carriage accompanying mechanism includes a longitudinal rail 15, a carriage 1, an accompanying frame operating rail 4, an accompanying frame 6, a telescopic frame operating rail 5, a telescopic frame 9 and a connecting frame 17, and the longitudinal rail 15 is fixedly arranged , the carriage 1 is slidably connected on the longitudinal rail 15 through the lifting traveling wheels 16, and the fixed frame at the bottom end of the carriage 1 is provided with an accompanying frame running track 4 arranged in an inner and outer direction, and the accompanying frame 6 passes through the traveling frame traveling wheels 3 Slidingly connected on the running track 4 of the accompanying frame, the bottom end of the accompanying frame 6 is fixedly provided with a telescopic frame running track 5 arranged in the left and right directions, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com