A high temperature resistant silicate luminous ceramic glaze and its preparation method

A technology of luminescent ceramics and silicates, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of glaze defects, high temperature resistance, unfavorable production and application of luminescent ceramics, etc., to achieve good light storage capacity and luminous intensity, The effect of improving high temperature resistance and good luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

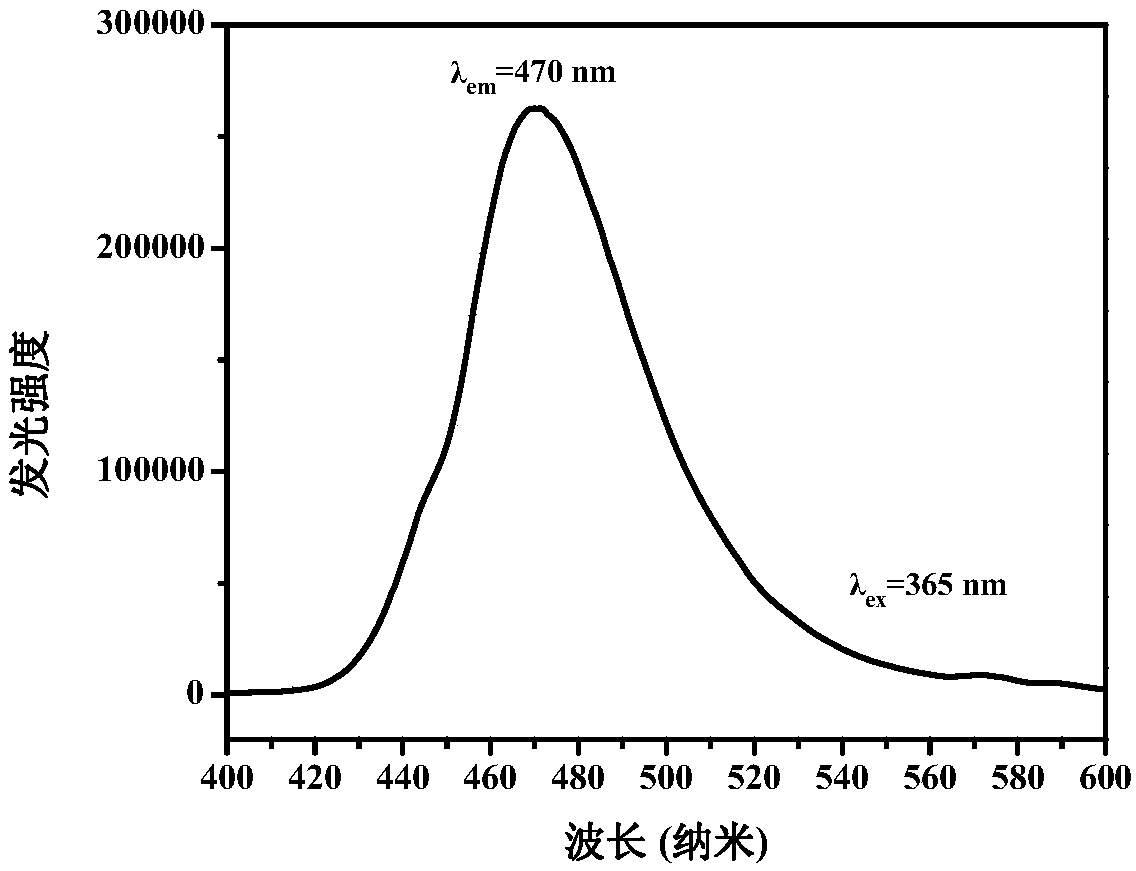

Embodiment 1

[0057] The preparation method of the high temperature resistant silicate luminous ceramic glaze of this embodiment comprises the following steps:

[0058] (1) Preparation of rare earth activated alkaline earth metal silicate luminescent material precursor: the chemical composition expression of rare earth activated alkaline earth metal silicate luminescent material is M 2-x-y MgSi 2 o 7 : Eu x , Ln y , where M is Sr element, Ln is rare earth Dy element, x=0.01, y=0.03. Accurately measure Si(OC 2 h 5 ) 4 60ml, then add 33ml deionized water and 84ml absolute ethanol. Accurately weigh SrCO 3 39.89g, Eu 2 o 3 0.24g, Dy 2 o 3 0.76g, MgO 5.40g were dissolved in appropriate amount of dilute nitric acid solution, H 3 BO 3 4g was dissolved in appropriate amount of deionized water. The above solutions were mixed, stirred evenly to obtain a transparent homogeneous solution, and an appropriate amount of ammonia water was added to adjust the pH value to 1. Then keep st...

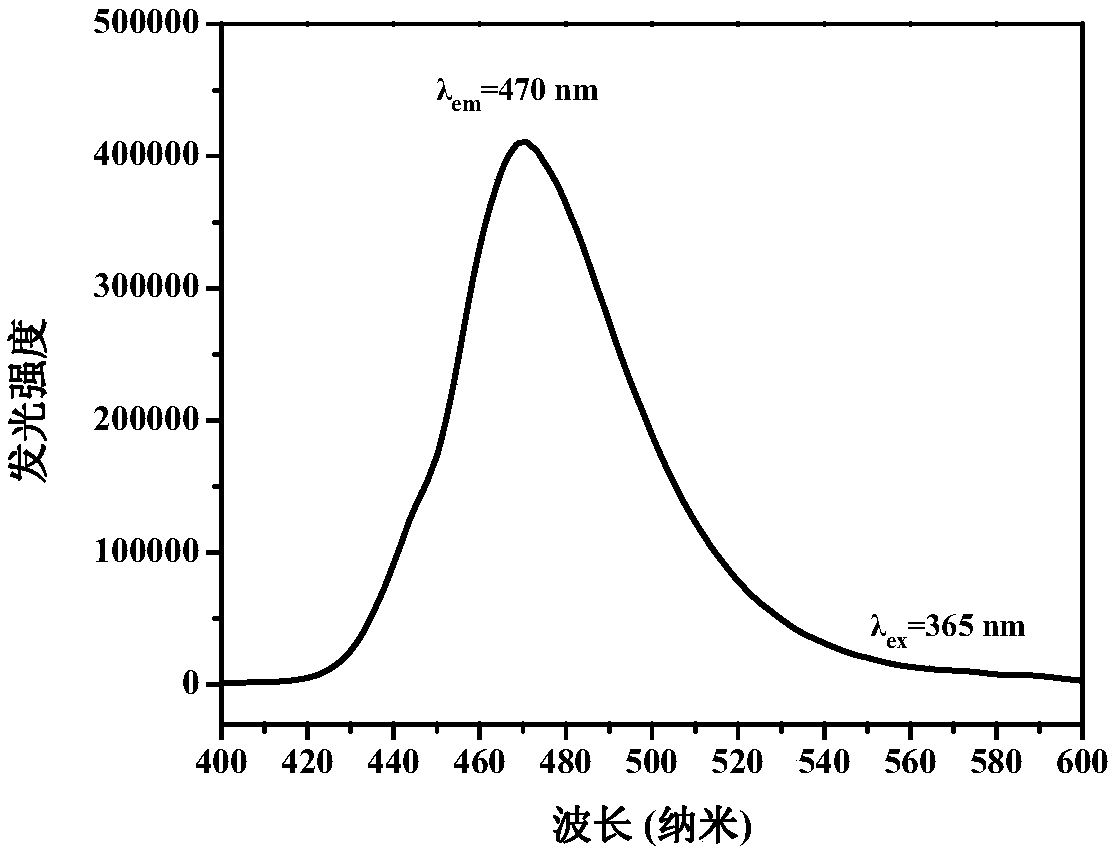

Embodiment 2

[0070] The preparation method of the high temperature resistant silicate luminous ceramic glaze of this embodiment comprises the following steps:

[0071] (1) Preparation of rare earth activated alkaline earth metal silicate luminescent material precursor: the chemical composition expression of rare earth activated alkaline earth metal silicate luminescent material is M 2-x-y MgSi 2 o 7 : Eu x , Ln y , where M is Sr element, Ln is rare earth Dy element, x=0.01, y=0.03. Accurately measure Si(OC 2 h 5 ) 4 60ml, then add 33ml deionized water and 84ml absolute ethanol. Accurately weigh SrCO 3 39.89g, Eu 2 o 3 0.24g, Dy 2 o 3 0.76g, MgO 5.40g were dissolved in appropriate amount of dilute nitric acid solution, H 3 BO 3 4g was dissolved in appropriate amount of deionized water. The above solutions were mixed and stirred evenly to obtain a transparent homogeneous solution, and an appropriate amount of ammonia water was added to adjust the pH value to 5. Then keep...

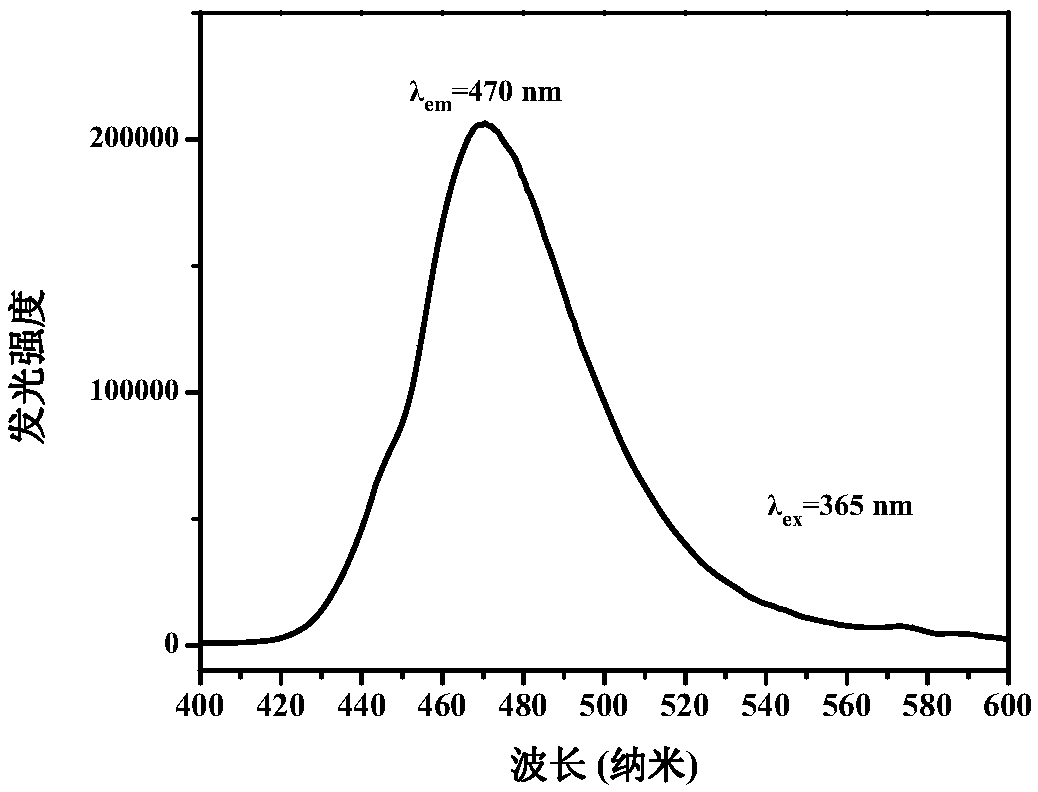

Embodiment 3

[0083] The preparation method of the high temperature resistant silicate luminous ceramic glaze of this embodiment comprises the following steps:

[0084] (1) Preparation of rare earth activated alkaline earth metal silicate luminescent material precursor: the chemical composition expression of rare earth activated alkaline earth metal silicate luminescent material is M 2-x-y MgSi 2 o 7 : Eu x , Ln y , where M is Sr element, Ln is rare earth Dy element, x=0.01, y=0.03. Accurately measure Si(OC 2 h 5 ) 4 60ml, then add 33ml deionized water and 84ml absolute ethanol. Accurately weigh SrCO 3 39.89g, Eu 2 o 3 0.24g, Dy 2 o 3 0.76g, MgO 5.40g were dissolved in appropriate amount of dilute nitric acid solution, H 3 BO 3 4g was dissolved in appropriate amount of deionized water. The above solutions were mixed and stirred evenly to obtain a transparent homogeneous solution, and an appropriate amount of ammonia water was added to adjust the pH value to 10. Then kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com