A packaging structure on a drinking water bucket

A drinking water bucket and packaging structure technology, which is applied to the sealing with auxiliary devices, sealing parts with unloading devices, packaging, etc., can solve the problems of high cost, troublesome water change, and cracking of smart seats, and achieve assembly and maintenance. The package is fast and convenient, and the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

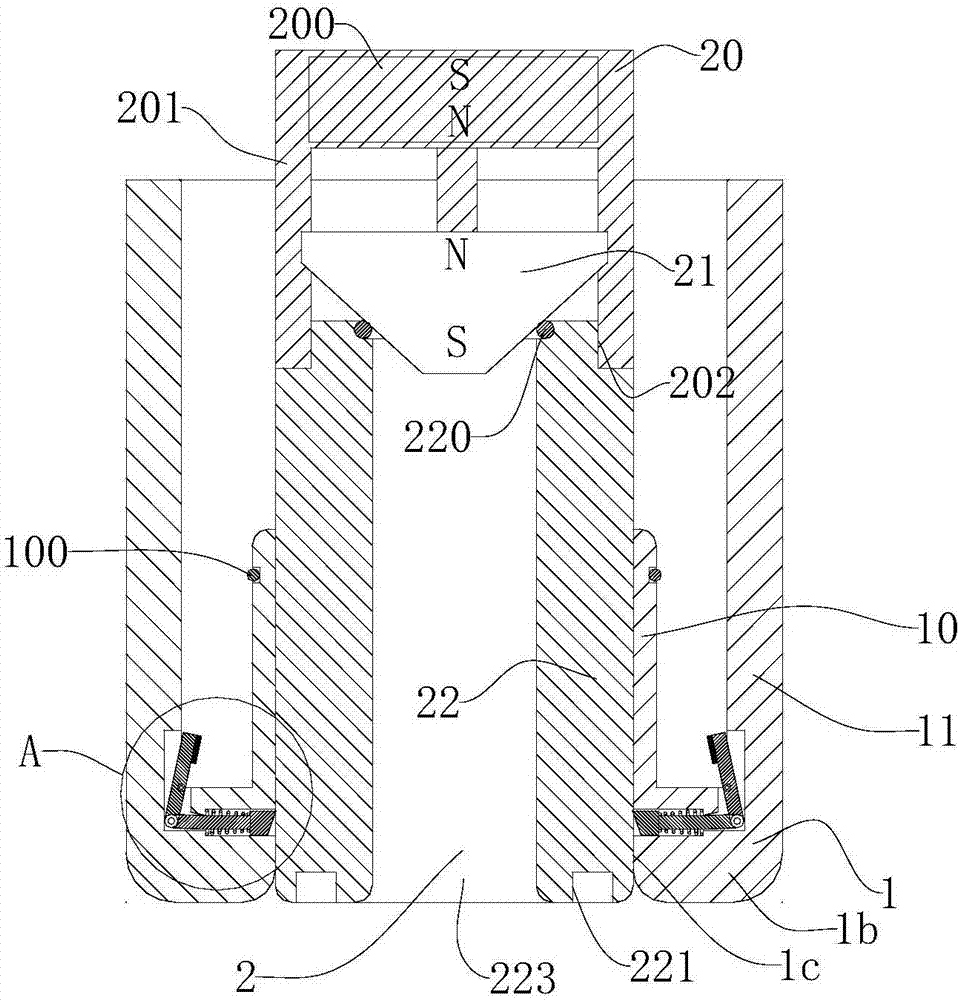

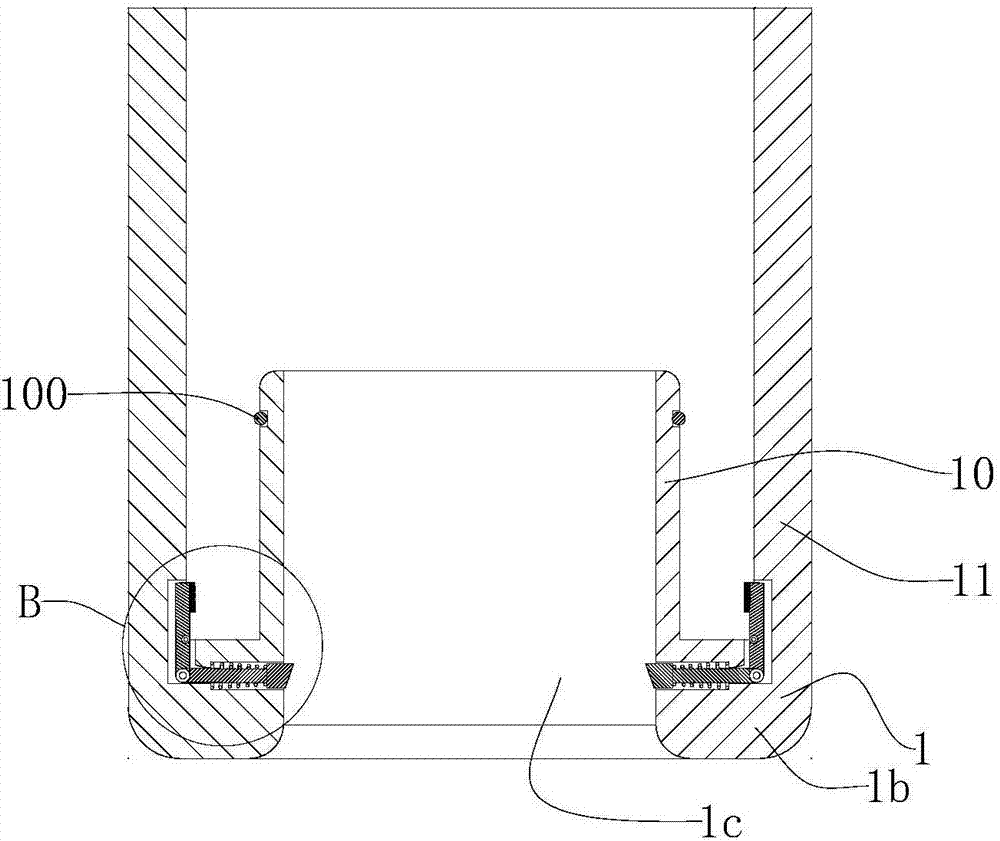

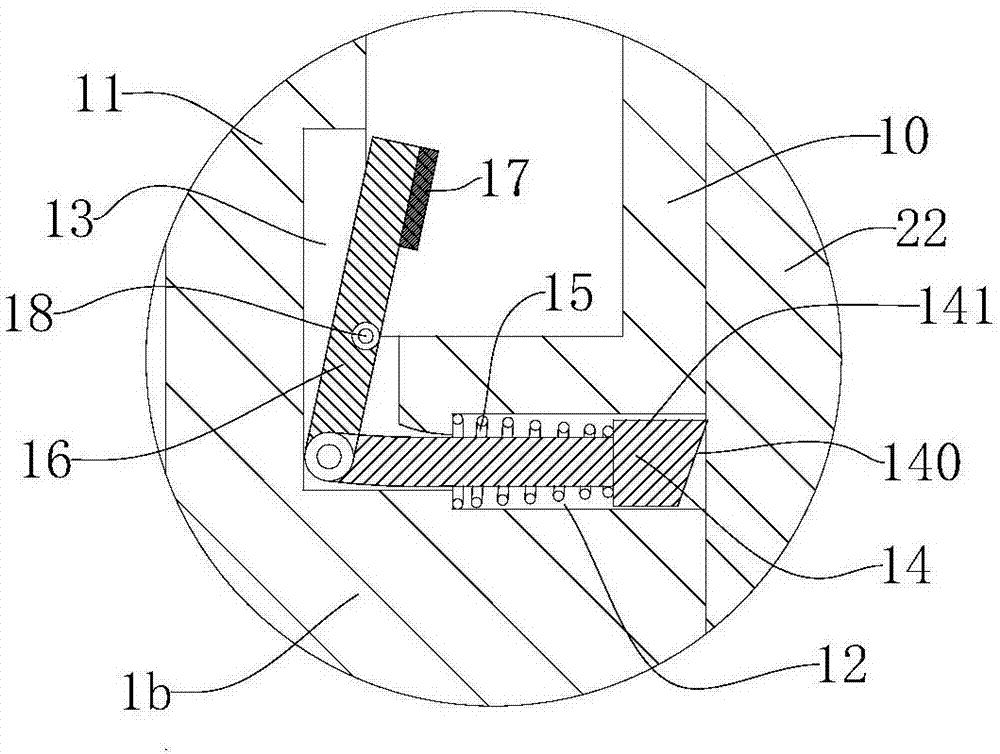

[0029] Such as Figure 1-6 Shown is a packaging structure on a drinking water barrel 3, which is composed of a hard shell part 1 and a hard leaking core part 2 for fixing the mouth part 30 of the drinking water barrel. Wherein, the hard shell part 1 includes a peripheral part 11 surrounding the outer wall of the mouth of the drinking water barrel, an inner peripheral part 10 attached to the inner wall of the mouth of the drinking water barrel, and a connection for connecting the lower end of the outer peripheral part 11 and the lower end of the inner peripheral part 10. The ring part 1b, specifically, the peripheral part 11 is higher than the inner peripheral part 10, the outer peripheral part of the connecting ring part 1b is connected with the lower end of the peripheral part 11, and the inner peripheral part of the connecting ring part 1b is connected with the lower end of the inner peripheral part. The peripheral part 11 , the inner peripheral part 10 and the connecting ri...

Embodiment 2

[0040] The encapsulation structure on the drinking water barrel of another structure, such as Figure 7 Shown, wherein the difference with embodiment 1 is:

[0041] The outer end surface of the push rod 14 is an inclined upward slope, and the inclined surface of the outer end of the push rod 14 corresponds to the lower end of the clamping part 16; Position to the torsion spring 19 of the slotted hole 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com