Jetting height error compensation method for large-area micro-nano structure electrohydrodynamics printing

A technology of micro-nano structure and height error, applied in printing and other directions, can solve problems such as affecting the precise formation of functional devices, affecting the structure and morphology of large-area micro-nano devices, and limiting large-area micro-nano structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

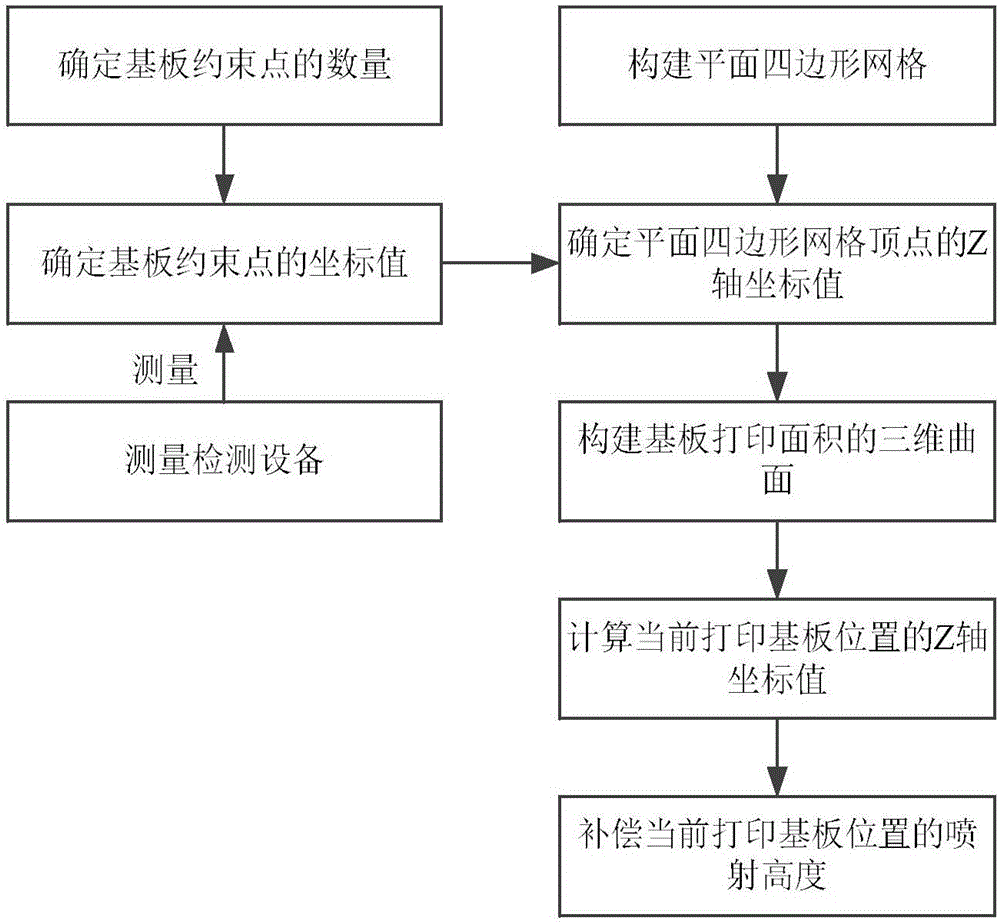

[0037] Such as figure 1 As shown, a jet height error compensation method for electrohydrodynamic printing of large-area micro-nanostructures includes the following steps:

[0038] 1. Determine the number of substrate constraint points.

[0039]According to the electrohydrodynamic printing area, determine the number of constraint points, determine the number of constraint points on the X-axis and Y-axis in the XY plane of the substrate as N and M, generally N≥3, M≥3, the larger the printing area , the larger the value of N and M, the number of constraint points is N×M, and the X-axis and Y-axis positions of each constraint point are obtained according to the moving distance of the motion platform of the electrohydrodynamic device, and the N×M The coordinates of a constraint point on the XY plane are (x i ,y i ) N×M , where 1≤i≤N×M.

[0040] 2. Determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com