Method and device for ink-jet printing on surface of cylinder,equipment and storage medium

A printing medium and inkjet printing technology, applied in printing devices, printing, typewriters, etc., can solve problems such as error accumulation, achieve the effects of improving accuracy, ensuring printing quality, and preventing mechanical error accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

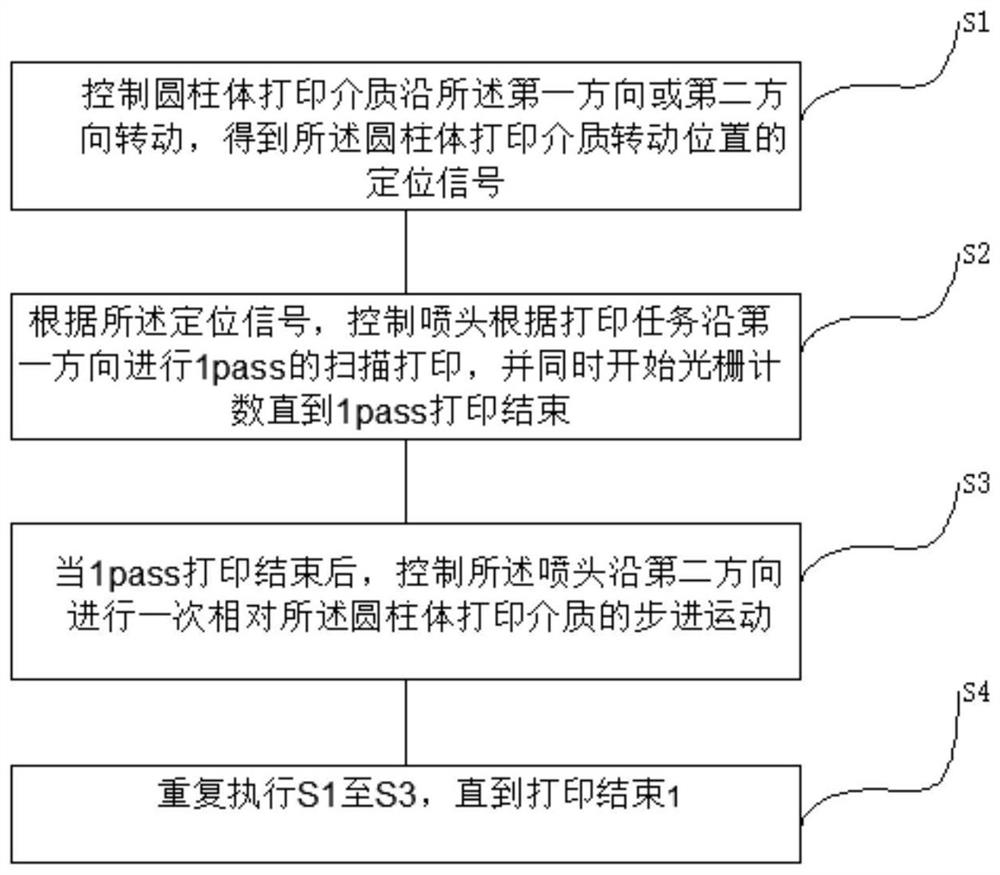

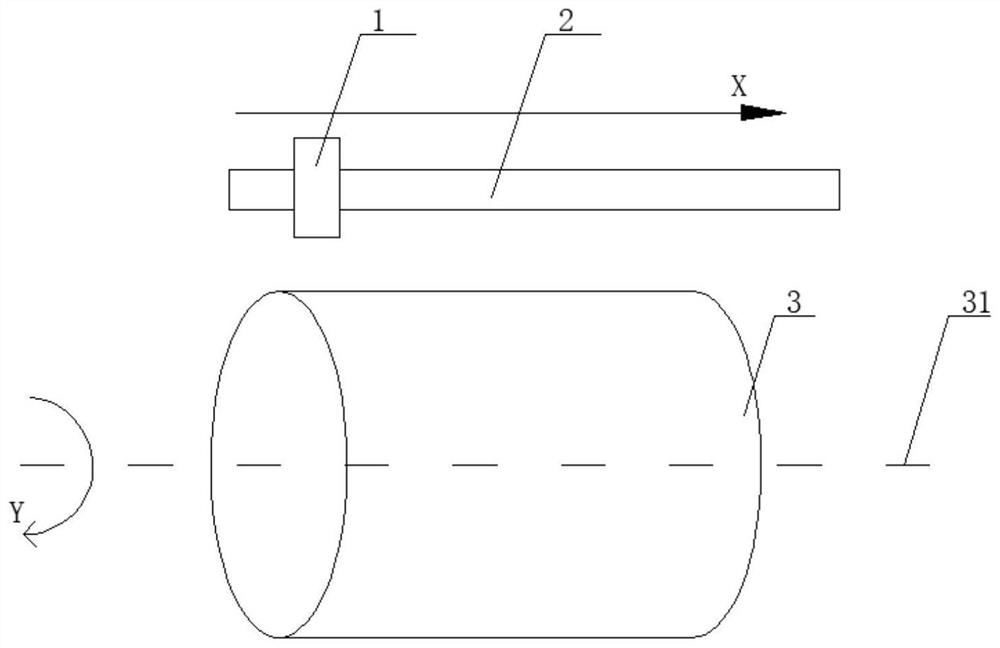

[0062] Such as figure 1 As shown, Embodiment 1 of the present invention discloses a method of inkjet printing on the surface of a cylinder. The nozzle performs a scanning movement along the first direction for 1 pass. After the 1-pass printing is completed, the nozzle performs a step along the second direction. Movement, start the next 1pass printing, the first direction and the second direction are perpendicular to each other; the method includes:

[0063] S1: controlling the rotation of the cylindrical printing medium along the first direction or the second direction, and obtaining a positioning signal of the rotational position of the cylindrical printing medium;

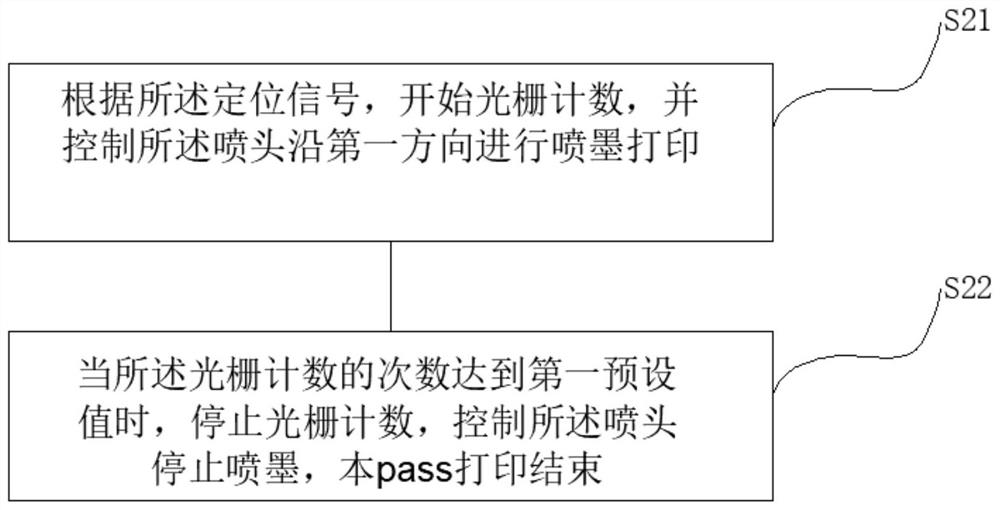

[0064] S2: According to the positioning signal, control the nozzle to perform 1-pass scanning and printing along the first direction according to the printing task, and start raster counting at the same time until the 1-pass printing is completed;

[0065] S3: After the 1pass printing is completed, control the n...

Embodiment 2

[0108] The invention provides a device for inkjet printing on the surface of a cylinder, such as Figure 7 As shown, the nozzle performs a scanning motion along the first direction for 1 pass. After the 1-pass printing is completed, the nozzle performs a stepping motion along the second direction to start the next 1-pass printing. The first direction and the second direction are mutually vertical, including:

[0109] Signal positioning module: used to control the cylindrical printing medium to rotate around the axis of the cylindrical printing medium to obtain the positioning signal of the rotational position of the cylindrical printing medium;

[0110] Printing control module: used to control the nozzle to perform 1-pass scanning and printing along the first direction according to the positioning signal, and simultaneously start raster counting until the 1-pass printing is completed;

[0111] Motion control module: used to control the nozzle to perform a stepping motion rela...

Embodiment 3

[0114] Embodiment 3 of the present invention discloses a device for inkjet printing on the surface of a cylinder, such as Figure 8 As shown, includes at least one processor, at least one memory, and computer program instructions stored in the memory.

[0115] Specifically, the above-mentioned processor may include a central processing unit (CPU), or an Application Specific Integrated Circuit (ASIC), or may be configured to implement one or more integrated circuits in the embodiments of the present invention.

[0116] Memory may include mass storage for data or instructions. By way of example and not limitation, the memory may include a Hard Disk Drive (HDD), a floppy disk drive, a flash memory, an optical disk, a magneto-optical disk, a magnetic tape, or a Universal Serial Bus (USB) drive or two or more a combination of the above. Storage may include removable or non-removable (or fixed) media, where appropriate. The memory may be internal or external to the data processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com