Equipment of automatic pressurizing mold of escalator handrail belt

A technology of automatic pressurization and handrails, applied in escalators, transportation and packaging, etc., can solve the problems of harmful gas harmful to the human body, accidental injury of processing personnel, and low processing efficiency, so as to reduce the harm to human body burns, reduce the Harm to the human body, the effect of improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

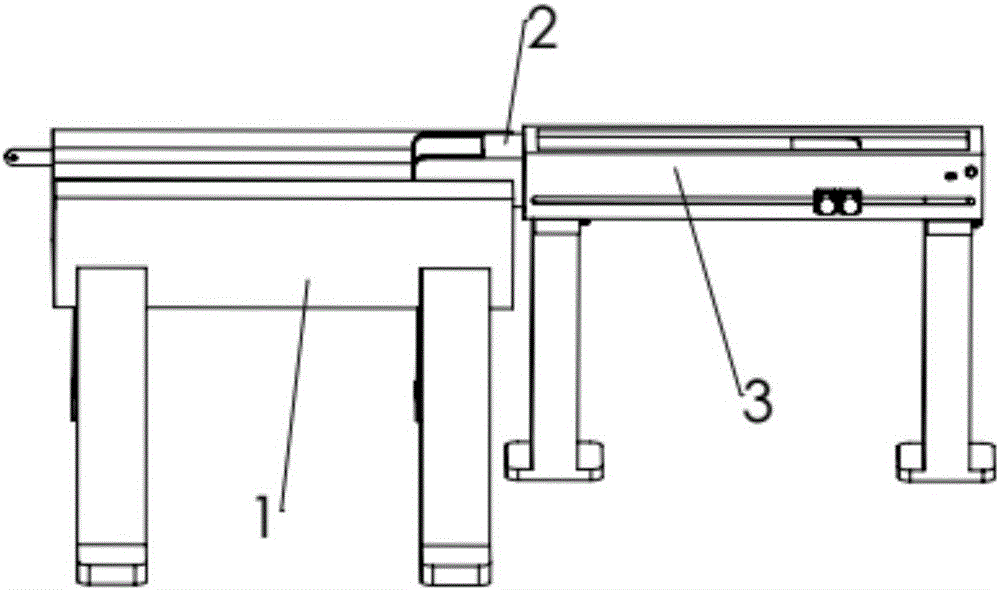

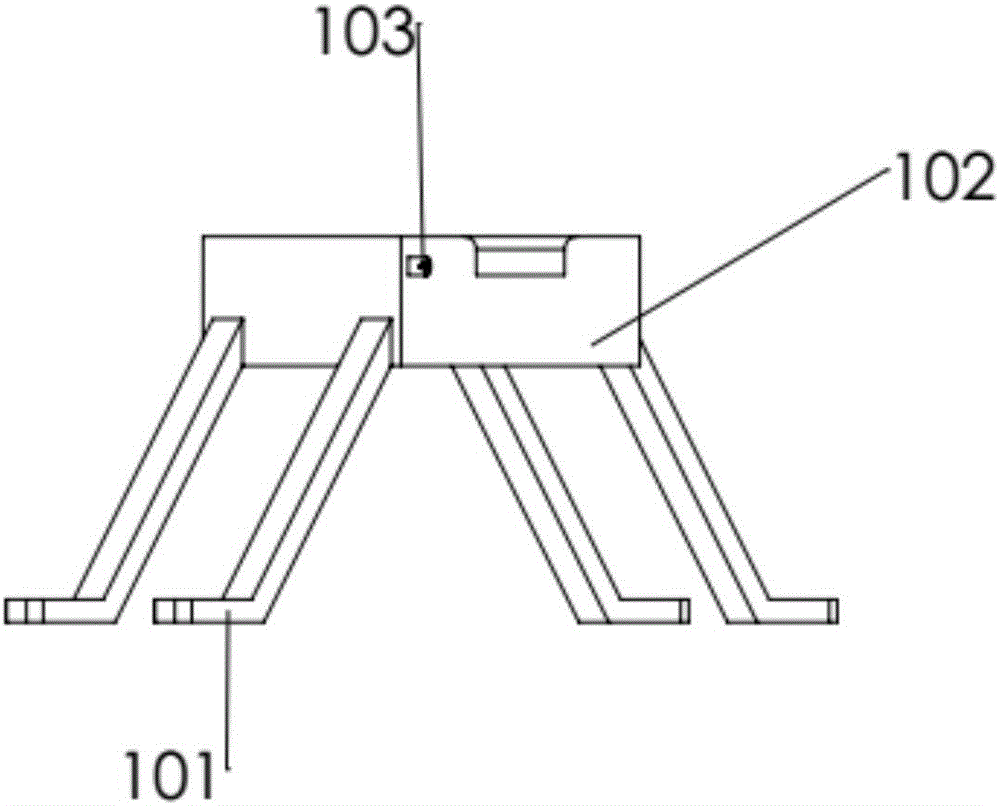

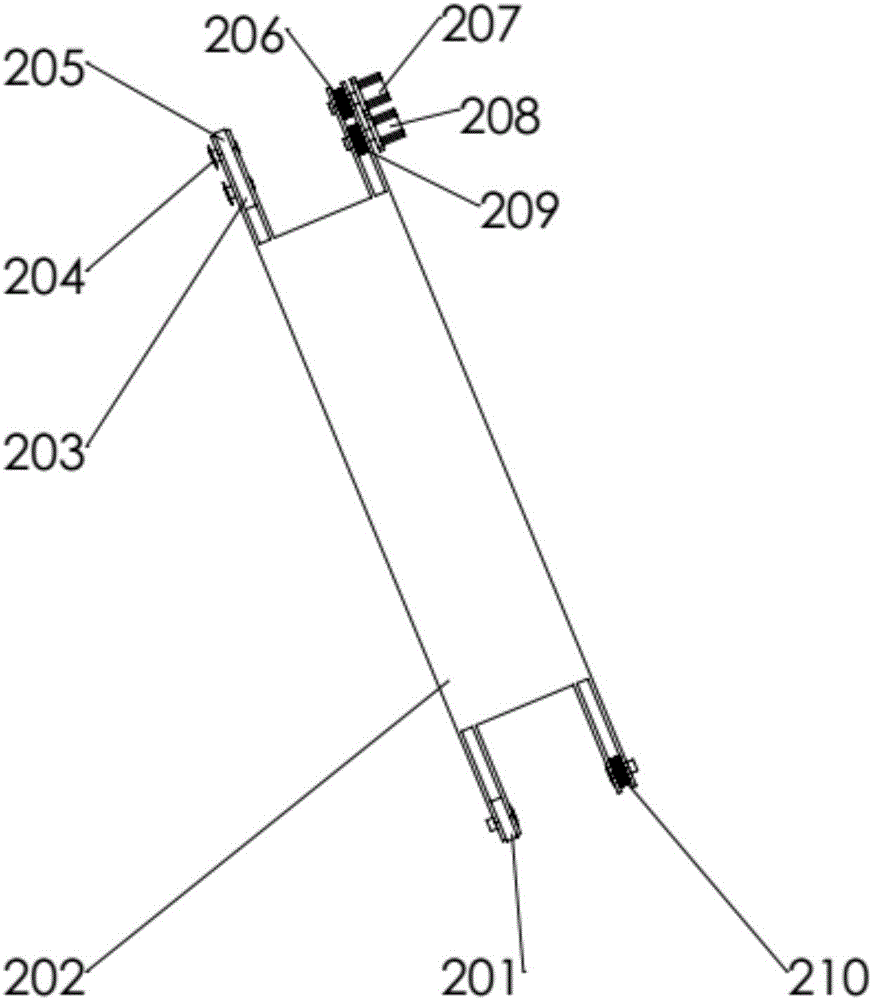

[0018] An elevator handrail belt automatic pressure mold equipment is composed of a pressure support body 1, a mold device 2 and a frame device 3, and the pressure support body 1 is composed of a support leg 101, a concave body 102 and an infrared Sensor one 103 is formed, and described mold device 2 is made up of roller one 201, square mold 202, roller two 203, mating pin 204, roller three 205, gear one 206, motor one 207, motor two 208, gear two 209 and Gear three 210 is made up of, and described frame device 3 is made up of frame leg one 301, frame leg two 302, rack one 303, motor three 304, gear four 305, drive shaft 306, frame body 307, inner rack 308, gear five 309, rack two 310, infrared sensor two 311, start button 312 and infrared sensor three 313 are formed, four support legs 101 are installed on the bottom of concave body 102, and infrared sensor one 103 is installed on concave body 102 The front part of the front part, the first roller 201 is installed on the squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com