Skipping type automatic conveying device for armature shafts

A technology of automatic conveying device and armature shaft, which is applied in the direction of grinding feed motion, grinding machine parts, metal processing equipment, etc. and other problems, to achieve the effect of improving polishing processing accuracy, uniform feed rate, and reducing abnormal noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

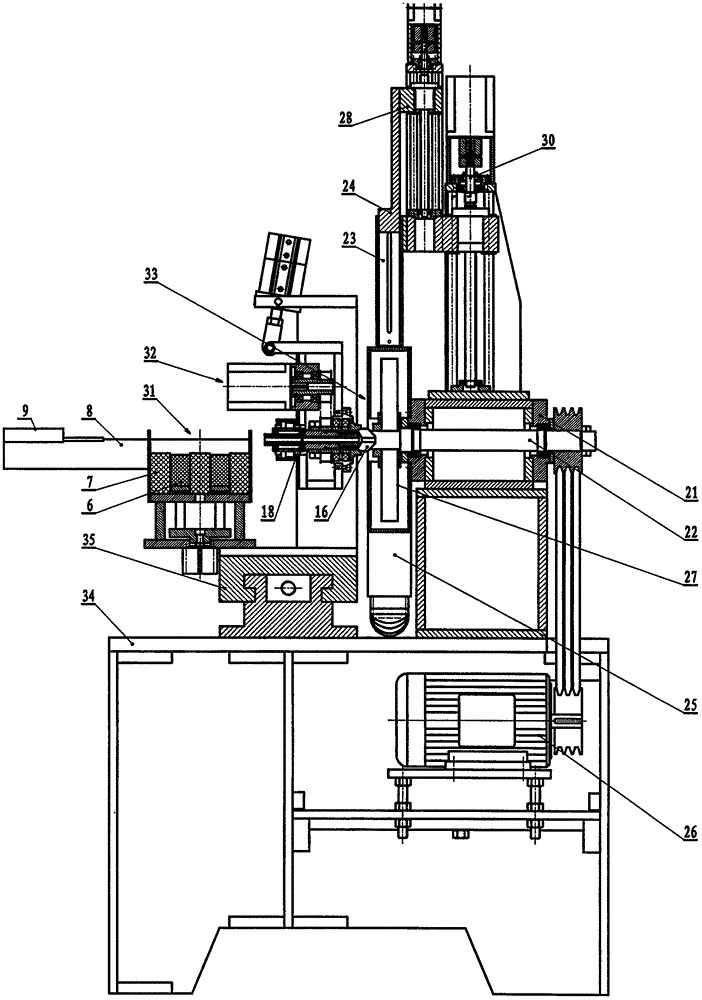

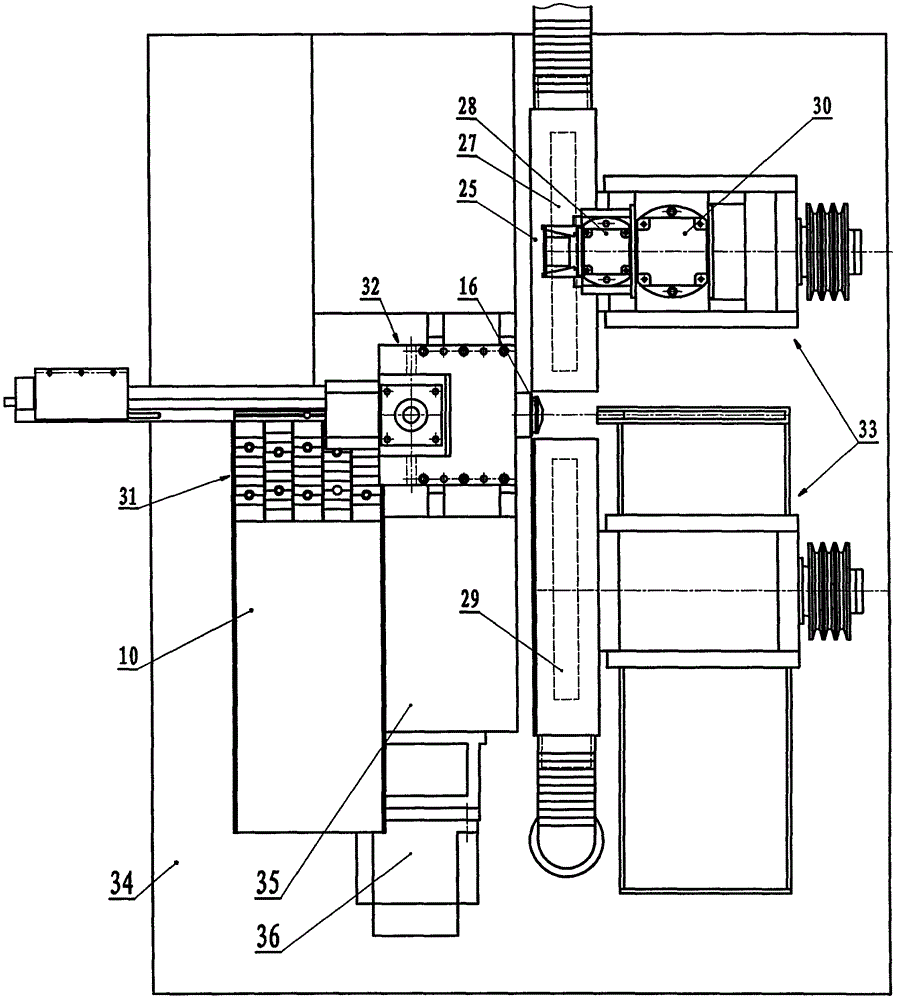

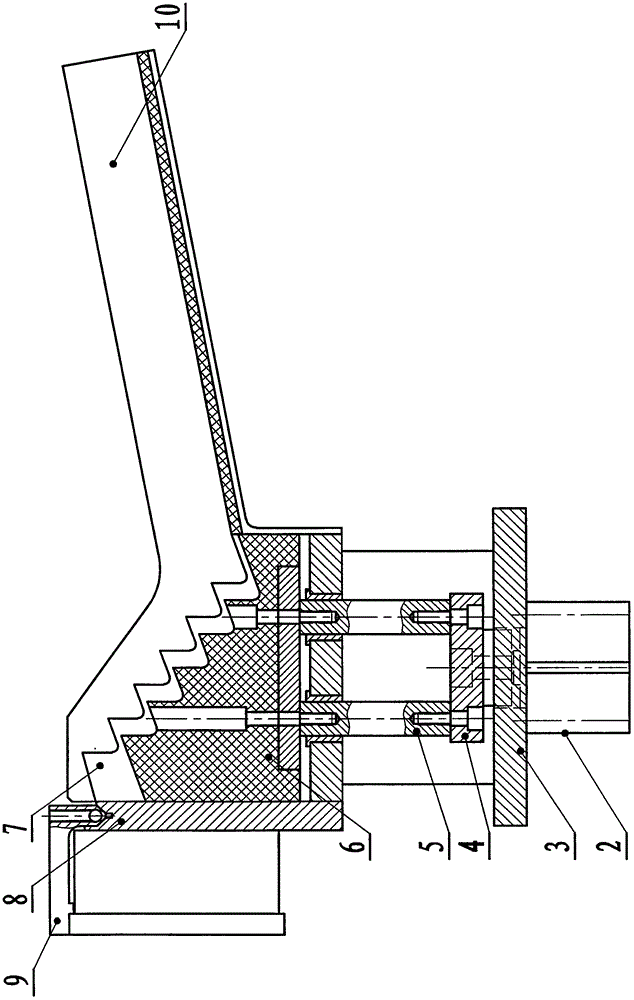

[0014] refer to image 3 , Figure 4 It can be seen that the jumping type armature shaft automatic conveying device of the present invention includes a material box 10 (with a certain slope) and a feeding bracket 3, and the material box 10 is connected with the fixed step 7 (and is fixed on the feeding bracket 3). The feeding power source 2 (feeding cylinder) is housed on the feeding support 3, and the feeding power source 2 links to each other with the feeding push plate 5 through the feeding connector 4, on the described feeding push plate 5, and with the ( In the middle) a movable step 6 is installed at the corresponding place, and a pusher block 9 is installed on the top of the step of the fixed step 7 through a material positioning plate 8 (with a groove for placing the armature shaft). 1 (for pushing material cylinder, it can be contained on the material positioning plate 8) links to each other.

[0015] Such as Figure 1 to Figure 6 , the armature shaft automatic fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com