Laser etching method and device, substrate electrode and electroluminescent device

A laser etching method and substrate electrode technology are applied in semiconductor devices, laser welding equipment, circuits, etc., and can solve problems such as lighting, adverse effects on device performance, and device leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

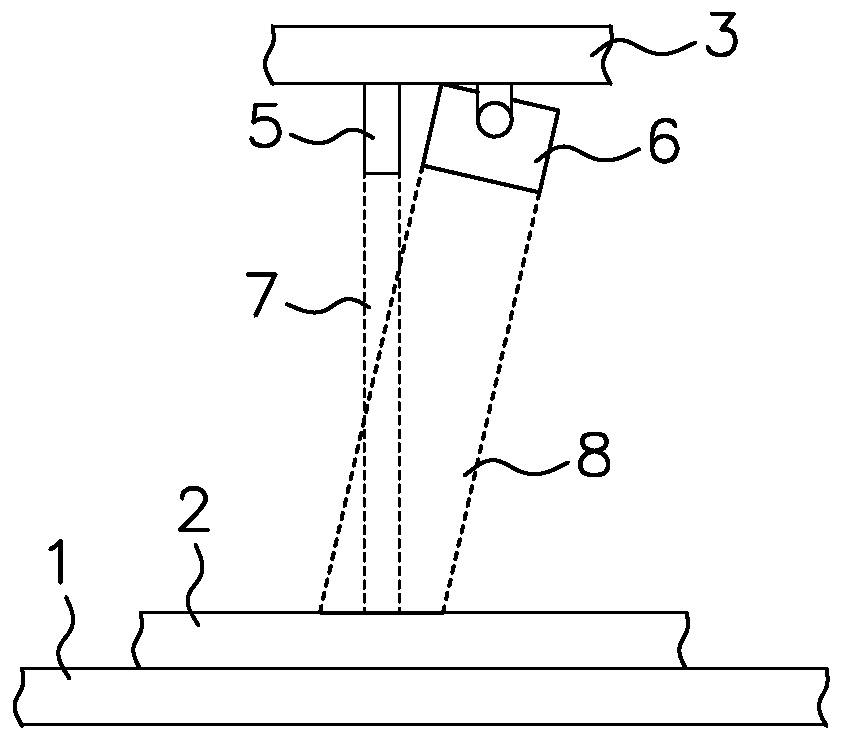

[0056] Such as figure 1 As shown, a kind of laser engraving machine that this embodiment provides, comprises the working platform 1 that is used to fix the object to be etched, and is arranged on the support 3 above the working platform 1, and the laser (comprising main laser 5) is installed on the support 3 and auxiliary laser 6), relative movement can occur between the working platform 1 and the support 3, and the relative movement can be in the horizontal direction or in the vertical direction.

[0057] The object to be etched includes a substrate coated with a conductive material. On the side coated with the conductive material, at least one region to be etched is provided on the object to be etched.

[0058] In this embodiment, the laser includes a main laser and an auxiliary laser.

[0059] Such as figure 2 show, combine figure 1 It can be seen that corresponding to one main laser 5, there may be one auxiliary laser 6. The main laser 5 is used to emit the main lase...

Embodiment 2

[0072] Such as Figure 12 As shown, a laser etching machine provided in this embodiment includes a working platform 1 for fixing the object to be etched, and a laser 4 arranged above the working platform 1, and a relative relationship between the working platform 1 and the laser 4 can occur. The relative movement can be horizontal or vertical.

[0073] The object to be etched 2 includes a substrate coated with a conductive material. On the side coated with the conductive material, at least one region to be etched is provided on the object to be etched.

[0074] Depend on Figure 12 and Figure 13 It can be seen that between the working platform 1 and the laser 4, the laser etching machine of this embodiment is also provided with an optical device for dividing the initial laser beam emitted by the laser into a main laser beam and an auxiliary laser beam.

[0075] Such as Figure 12 As shown, the optical device includes a total reflection mirror 12 having a through hole, an...

Embodiment 3

[0080] Take the ITO substrate as the object to be etched as an example, and use the laser etching machine in Embodiment 1 to etch it. The laser etching method includes:

[0081] (1) The front side of the ITO substrate to be etched (that is, the side provided with the ITO conductive material) is placed on the working platform of the laser etching machine and positioned;

[0082] (2) Adjust the distance between the working platform and the support, move the main laser to the top of the first area to be etched, so that the focus of the main laser beam falls on the first area to be etched;

[0083] (4) Input or import the ITO pattern to be etched into laser engraving software;

[0084] (5) Adjust the tilt angle of the auxiliary laser (when using figure 1 and Figure 8 The shown laser etching machine needs to adjust the tilt angle of the auxiliary laser, when using image 3 Not required for the laser engraving machine shown), adjust the beam size of the main laser beam and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com